Lactobacillus johnsonii, microbial inoculum, application and premix thereof

A Lactobacillus johnsonii, premix technology, applied in application, bacteria, animal feed, etc., to achieve strong gastric acid tolerance, good stress resistance, and improve production performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Verification of Stress Resistance of Lactobacillus johnsonii CGMCC No.4926

[0022] Inoculate 1 mL of Lactobacillus johnsoni CGMCC No.4926 bacteria solution into 10 mL of MRS medium, and incubate at 37°C for 20 hours, then take 3 mL of the bacterial suspension, centrifuge at 12,000 rpm for 5 minutes, discard the supernatant, and add 10ml pH 2.0, 1% pepsin artificial gastric juice, stand at 37°C for 2h; centrifuge at 12,000rpm for 5min, discard the supernatant, add the bacterial pellet to 10ml artificial bile salt with a concentration of 0.3%, let stand at 37°C for 3h . After oscillating and mixing, take 1 mL of the bacterial suspension and dilute it with sterile physiological saline gradient to coat the MRS medium plate. After anaerobic culture at constant temperature at 37°C for 20 h, colonies were purified. The strains obtained from the primary screening were further screened.

[0023] (1) Tolerance of artificial gastric juice

[0024] Inoculate 1 mL of ...

Embodiment 2

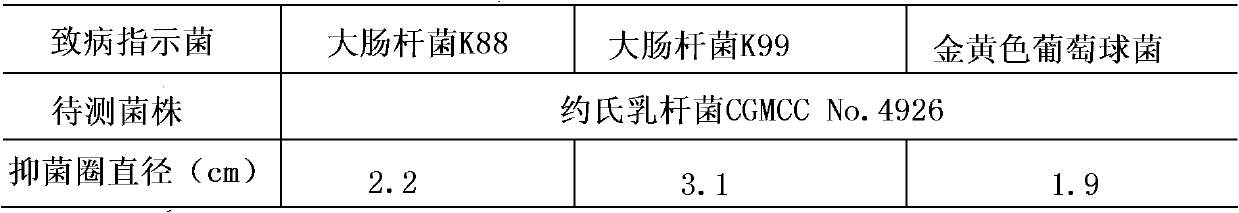

[0031] Example 2 Verification of Lactobacillus johnsonii CGMCC No.4926 antibacterial ability

[0032] Melt the LB solid medium and cool to 45°C. Add E.coli K88, K99 and Staphylococcus aureus cultured overnight (add 1 microliter of bacterial solution per milliliter of culture medium), shake and mix well, pour into a sterile plate, solidify horizontally, and place gently on each agar plate 4 Oxford cups should be equally spaced. Add 50 μL of Lactobacillus johnsonii bacteria solution to each Oxford cup, cover the dish cover, carefully move it to a 37°C incubator, and place the dish for static culture. After cultivating for 20 hours, open the lid of the dish, remove the Oxford cup, and measure the diameter of the inhibition zone with a caliper (results are shown in Table 1).

[0033] Table 1 Determination of inhibition zone

[0034]

example 3

[0035] The preparation of example 3 Lactobacillus johnsonii CGMCC No.4926 live bacteria preparation

[0036] Preparation of Lactobacillus johnsonii seed solution: Inoculate the strains preserved on the slant of the test tube into an anaerobic tube containing 20 mL of MRS medium, and culture at a constant temperature for 20 hours at 37°C until the number of viable bacteria reaches 10 7 CFU / mL, inoculate at 1% in a 250mL Erlenmeyer flask containing 100mL seed medium, culture anaerobically at 37°C for 20h, until the number of viable bacteria reaches 10 7 CFU / mL or more, as a seed solution for later use.

[0037] Seed liquid MRS medium is: peptone, 10.0g / L; beef extract, 8.0g / L; yeast extract, 4.0g / L; glucose, 20.0g / L; Tween 80, 1mL / L; dipotassium hydrogen phosphate, 2.0g / L; Sodium acetate trihydrate, 5.0g / L; Triammonium citrate, 2.0g / L; Magnesium sulfate heptahydrate, 0.2g / L; Manganese sulfate, 0.05g / L; Add distilled water to 1000mL, pH 6.2 ±0.2. liquid submerged fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com