Vertical heat pipe organic medium evaporation medium and low temperature flue gas waste heat power generation system

A low-temperature flue gas and waste heat power generation technology, which is applied in the field of energy and environment, can solve the problems of difficult replacement of heat exchange pipes, waste of organic working fluid, and decline in heat exchange efficiency, so as to meet process requirements, fully utilize heat energy, and improve heat transfer efficiency. The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

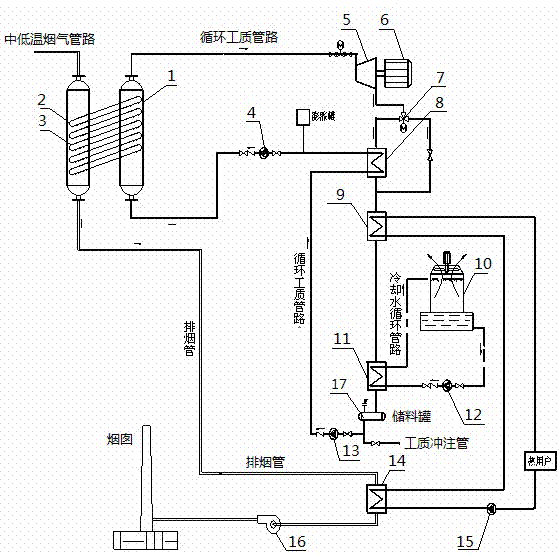

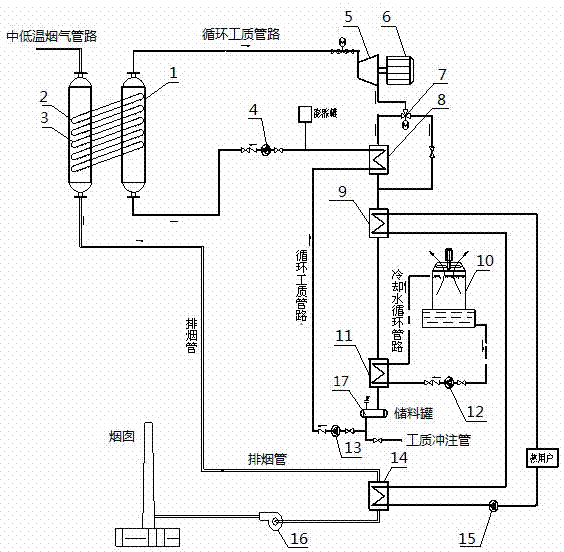

[0025]Example 1: A three-stage walking heating furnace on the high-speed line of a steel plant, a vertical heat pipe organic medium evaporation medium and low temperature flue gas waste heat power generation co-supply system is built, the motor output power is 10Kw, and it supplies 45-50 ℃ sanitary heat Water 600l / d.

[0026] The vertical heat pipe organic medium evaporation medium and low temperature flue gas waste heat power generation system includes a heat pipe heat exchange system, an organic working medium Rankine cycle, a medium and low temperature flue gas exhaust pipe, a heating and hot water circuit and a cooling water circuit; The heat system consists of a heat pipe 2, a flue gas heat exchanger 3 and a drum 1. The flue gas heat exchanger 3 and the drum 1 are arranged vertically, and the heat pipe 2 is a vertical inclined 60 0 For the two-phase thermosiphon set, the evaporation section at the lower end is placed in the flue gas heat exchanger 3, and the condensation ...

Embodiment 2

[0032] Example 2: This vertical heat pipe organic medium evaporation medium and low temperature flue gas waste heat power generation system is the same as Example 1, and the organic Rankine cycle working medium used is propane R290; the thermosiphon is vertically inclined 30 0 Set up, adopt two-phase thermosiphon, a total of 1000, each pipe is 4.5m long, and there are 32 enhanced heat transfer fins on the upper and lower sections respectively; the thermosiphon is filled with 25% V (heat pipe volume) softened and desalinated water.

Embodiment 3

[0033] Example 3: This vertical heat pipe organic medium evaporation medium and low temperature flue gas waste heat power generation system is the same as Example 1, and the organic Rankine cycle working fluids used are toluene, pentane R601, and tetrafluoroethane R134a, respectively 30% , 25%, 45% volume ratio; the thermosiphon is vertically inclined 50 0 Set up, using two-phase thermosiphon, a total of 900, each tube is 5.5m long, and there are 48 enhanced heat transfer fins on the upper and lower sections respectively; the thermosiphon is filled with 30% V (heat pipe volume) softened and desalinated water.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap