Lithium ion battery cathode material lanthanum strontium cobalt oxide and carbon coated lithium iron phosphate and preparation method thereof

A technology for coating lithium iron phosphate and lithium ion batteries, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor high-rate charge and discharge performance, and achieve improved discharge capacity, reduced corrosion, and excellent electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

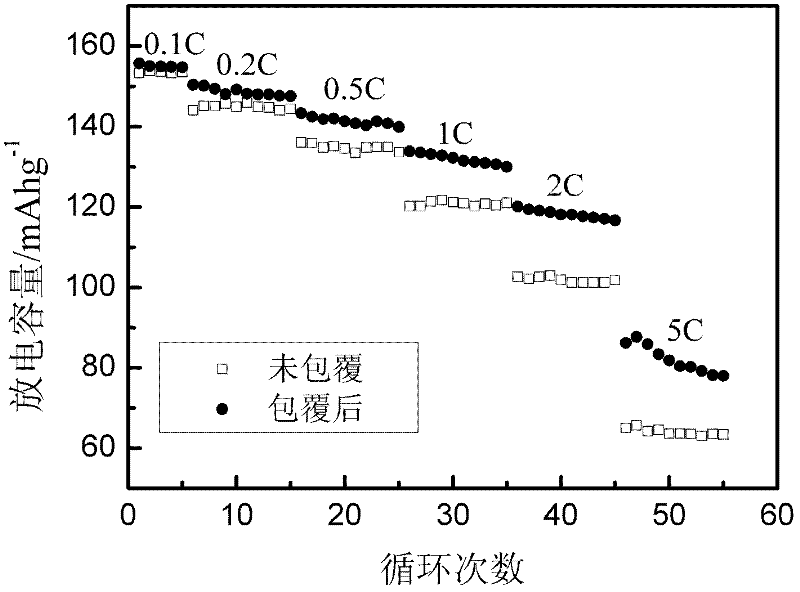

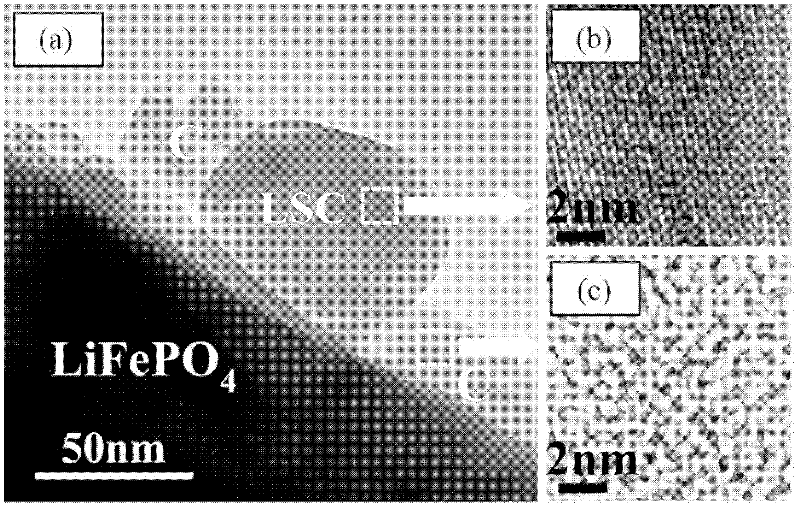

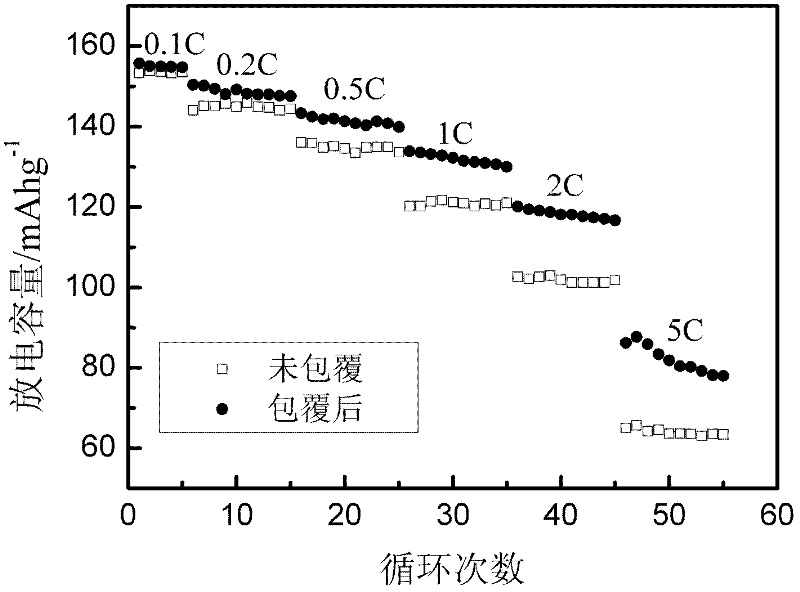

[0030] LiFePO prepared by carbothermal reduction method 4 +C (C content 3.58wt.%) was used as the matrix material, and the LSC powder prepared by the above-mentioned glycine combustion method was used as the coating. 2.97 grams of matrix materials were dispersed in 150 grams of absolute ethanol (mass concentration 1.9wt.%), 0.03 grams of LSC were dispersed in 20 grams of absolute ethanol (mass concentration 0.15wt.%), and the above two solutions were ultrasonically After shaking for 20 minutes, stir at room temperature for 4 hours. Add LSC alcohol suspension drop by drop to LiFePO 4 / C suspension, stirred at 60°C, and evaporated the mixed suspension until it became a paste. After that, it was dried in an oven, heat-treated at 400°C for 2 hours in a nitrogen atmosphere, ground, and sieved to obtain 1wt.% LSC-coated LiFePO 4 / C / LSC powder has good electrochemical performance. The battery was first charged and discharged at 0.1 rate for 5 cycles, and then charged and discharg...

Embodiment 2

[0032] LiFePO prepared by carbothermal reduction method 4 +C (C content 3.58wt.%) was used as the matrix material, and the above-mentioned glycine combustion method was used to prepare LSC. Take 2.94 grams of LiFePO 4 / C material is dispersed in 150 grams of absolute ethanol (mass concentration 1.9wt.%), 0.06 grams of LSC is dispersed in 30 grams of absolute ethanol (mass concentration 0.2wt.%), and stirred at room temperature after ultrasonic oscillation for 20 minutes 4 hours; then add the LSC solution drop by drop to LiFePO under the premise of heating and stirring at 25°C 4 / C solution, continue to heat and stir at this temperature to evaporate the liquid until it becomes a paste, then dry it in an oven below 70°C, heat-treat at 400°C for 2 hours in a nitrogen atmosphere, grind, and pass through a 280-mesh sieve to obtain 2wt.% LSC coated LiFePO 4 / C / LSC powder. The battery was first charged and discharged at 0.1 rate for 5 cycles, and then charged and discharged at 0....

Embodiment 3

[0034] LiFePO prepared by carbothermal reduction method 4 +C (C content 3.58wt.%) material, LSC was prepared by the above-mentioned glycine combustion method. Take 2.91 grams of LiFePO 4 / C material is dispersed in 150 grams of absolute ethanol (mass concentration 1.9wt.%), 0.09 grams of LSC is dispersed in 45 grams of absolute ethanol (mass concentration 0.2wt.%), and stirred at room temperature after ultrasonic oscillation for 20 minutes 4 hours; then add the LSC alcohol suspension drop by drop to LiFePO under the premise of heating and stirring at 70°C 4 / C alcohol suspension, continue to heat and stir at this temperature to evaporate the liquid until it becomes a paste, then dry it in an oven below 70°C, heat-treat at 400°C for 2 hours in a nitrogen atmosphere, grind, and pass through 280 mesh Sieve to get 3wt.% LSC-coated LiFePO 4 / C / LSC powder. The battery was first charged and discharged at 0.1 rate for 5 cycles, and then charged and discharged at 0.2 rate, 0.5 rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com