Preparation method for polyaniline/ferroferric oxide compound with nucleus-shell structure

A technology of ferroferric oxide and polyaniline, which is applied in the direction of magnetism of organic materials/organic magnetic materials, can solve problems such as the limitation of microwave absorption performance, the inability to remove SDBS, and the impact, and achieve high component content and good microwave absorption function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

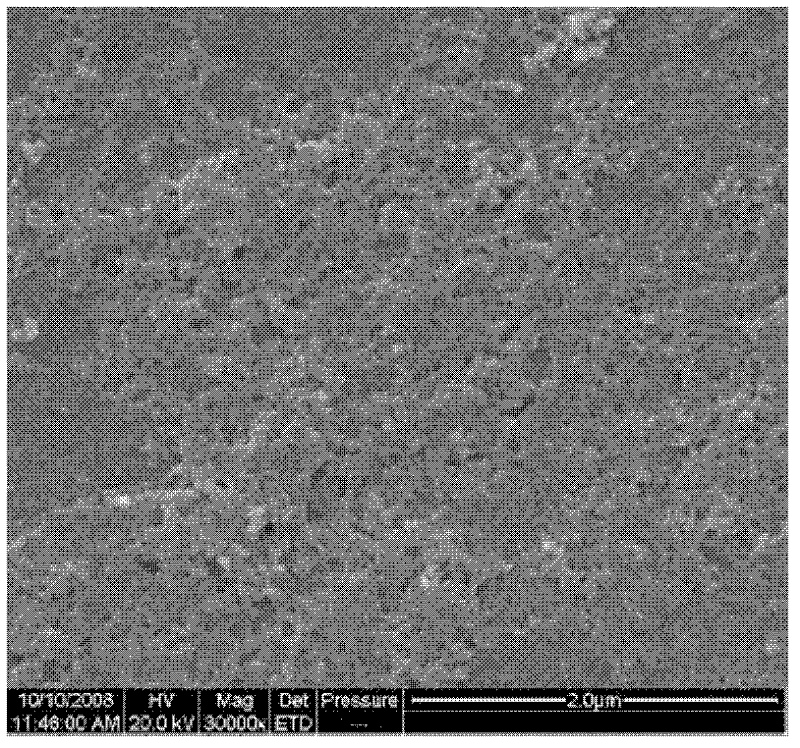

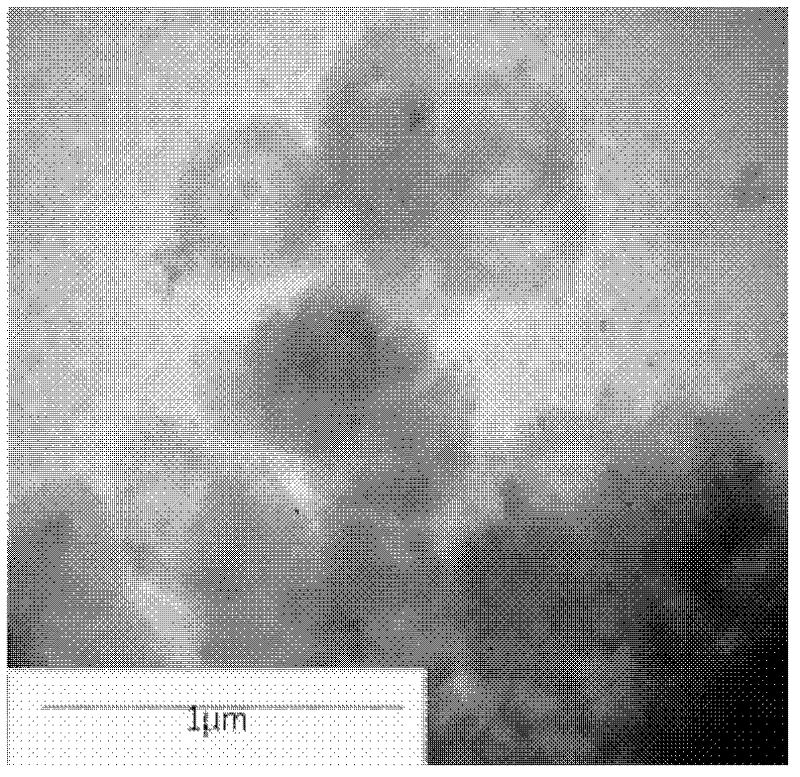

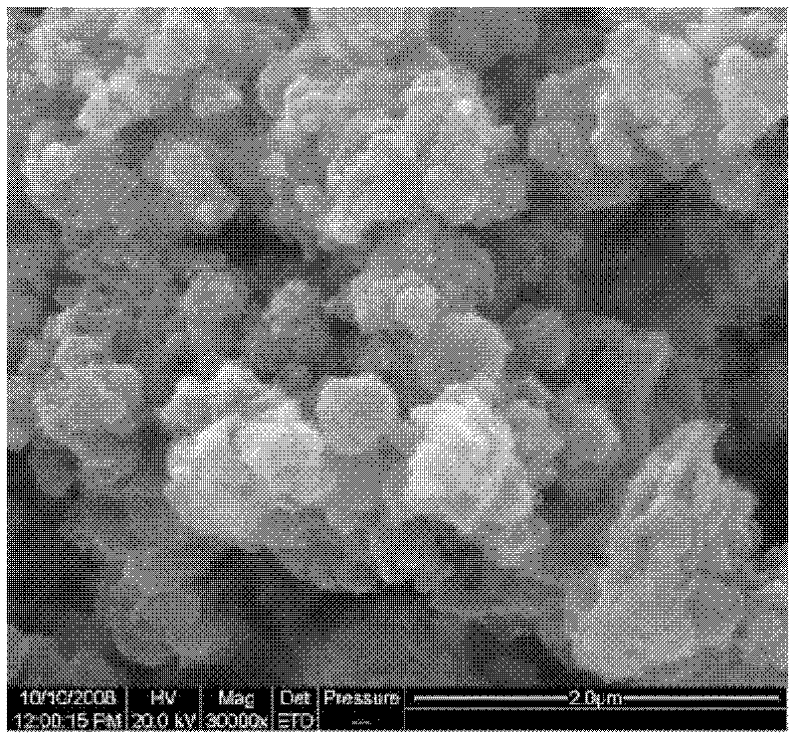

Image

Examples

Embodiment 1-5

[0028] The preparation method of the polyaniline / ferric oxide composite with core-shell structure of embodiment 1-5, concrete practice is:

[0029] a. Preparation of water-based magnetic fluid: Weigh 1.5-2.5 parts of polyethylene glycol and 1 part of ferric dichloride tetrahydrate, dissolve them in distilled water respectively, then mix and stir the two to obtain water-based magnetic fluid. Sol; add sodium hydroxide solution dropwise to the hydrosol to make the pH value 12.0-13.0, then add 0.05 parts by weight of hydrogen peroxide to the hydrosol, and then stir and react at 55-65°C for 4 hours to obtain dispersion Water-based ferrofluid with polyaniline / ferric oxide colloidal particles;

[0030] B, the adsorption treatment of initiator: add the initiator ammonium persulfate of aniline polymerization reaction in the water-based magnetic fluid obtained in a step, leave standstill for 8-32 hours after stirring, and complete the colloid of polyaniline / ferric oxide colloidal partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com