Method for improving aging performance of epoxidized natural rubber

A natural rubber aging performance technology, applied in the field of anti-aging performance control, can solve the problems of restricting the application and industrialization of epoxidized natural rubber, poor aging resistance, etc., to achieve improved anti-aging performance, low cost, and easy preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

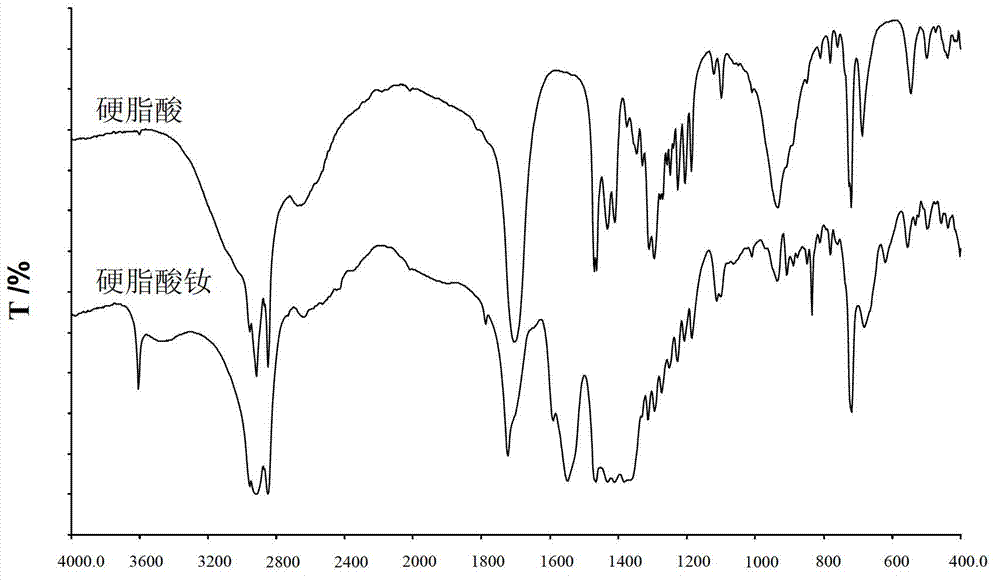

[0035] a Preparation of lanthanum stearate

[0036] Dissolve 4.8g (0.12mol) of sodium hydroxide in 100ml of water, slowly add 13g (0.04mol) of lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), the reaction was stirred at 80° C. for 30 min, followed by the addition of 30.48 g (0.12 mol) of stearic acid. The precipitate that reaction generates is filtered, then, vacuum-dried to constant weight, the structural formula that obtains white powder is (c 17 h 35 COO) 3 Lanthanum stearate of La, standby;

[0037] b component and number of servings

[0038] Epoxidized natural rubber with a degree of epoxidation of 10% 100; stearic acid 2; zinc oxide 5; accelerator NS 1.5; sulfur 1.5; lanthanum stearate 0.5.

[0039] c mixing and vulcanization

[0040] 1) Thinly pass the epoxidized natural rubber 10 times on the open mill (roll distance 1.4mm).

[0041] 2) Adjust the roller distance of the open mill to 0.2mm, and pass the rubber thinly twice without wrapping the roller.

[0042] 3) Adju...

Embodiment 2

[0055] a Preparation of lanthanum stearate

[0056] The preparation of lanthanum stearate is identical with embodiment 1.

[0057] b component and number of servings

[0058] Epoxidized natural rubber with 25% epoxidation degree 100; stearic acid 2; zinc oxide 5; accelerator NS 1.5; sulfur 1.5; lanthanum stearate 1.

[0059] c mixing and vulcanization

[0060] The mixing and vulcanization process and the hot air aging test are the same as in Example 1.

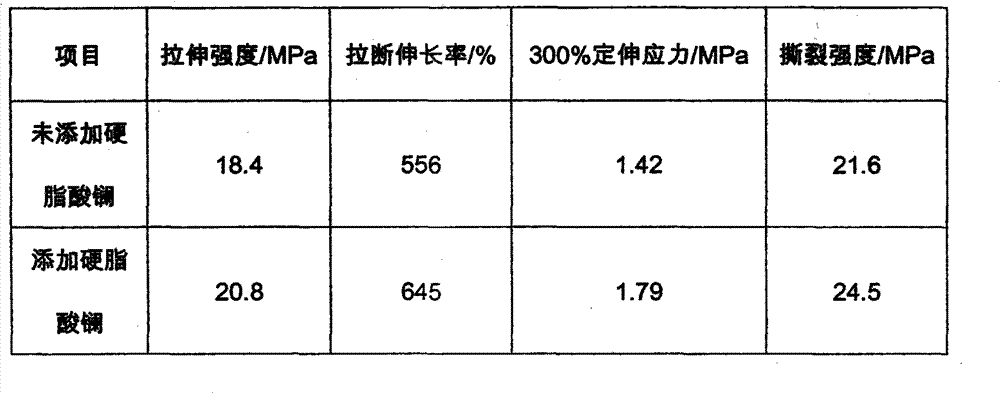

[0061] The mechanical properties of the epoxidized natural rubber vulcanizate with a degree of epoxidation of 25% are shown in Table 3. The tensile strength retention and elongation at break of the epoxidized natural rubber vulcanizate after aging in hot air at 100°C The rate retention rate is shown in Table 4.

[0062] Table 3 The mechanical properties of epoxidized natural rubber vulcanizate with epoxidation degree of 25%

[0063]

[0064] Table 4 Tensile strength retention and elongation at break of epoxidized natur...

Embodiment 3

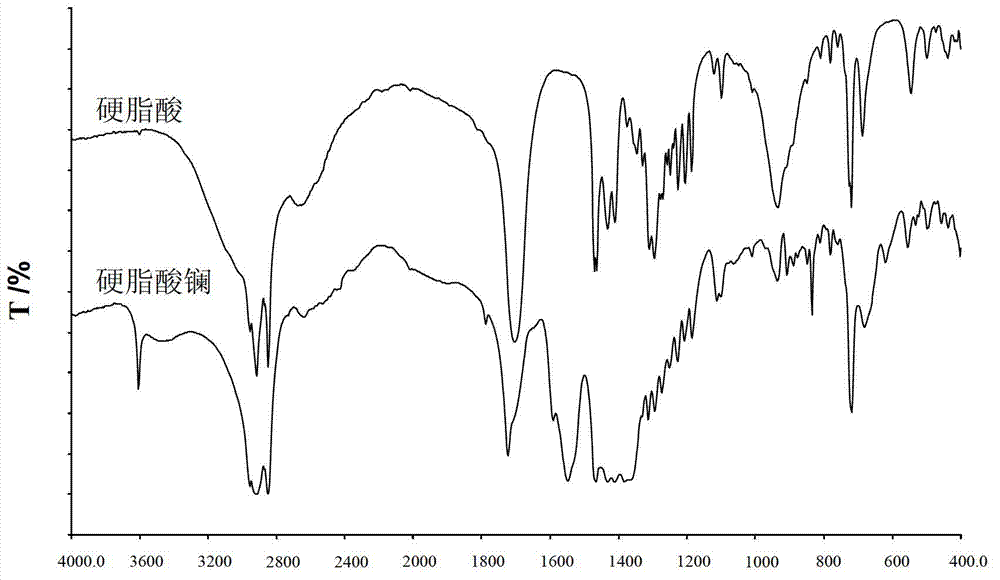

[0069] a Preparation of neodymium stearate

[0070] Dissolve 4.8g (0.12mol) of sodium hydroxide in 100ml of water, slowly add 13g (0.04mol) of neodymium nitrate (Nd(NO 3 ) 3 ·6H 2 O), the reaction was stirred at 80° C. for 30 min, followed by the addition of 30.48 g (0.12 mol) of stearic acid. The precipitate that reaction generates is filtered, then, vacuum-dried to constant weight, the structural formula that obtains white powder is (C 17 h 35 COO) 3 Neodymium stearate of Nd, spare;

[0071] b component and number of parts

[0072] Epoxidized natural rubber with 25% epoxidation degree 100; Stearic acid 2; Zinc oxide 5; Accelerator NS 1.5; Sulfur 1.5; Neodymium stearate 2.

[0073] The mixing and vulcanization process and the hot air aging test are the same as in Example 1.

[0074] The mechanical properties of the epoxidized natural rubber vulcanizate with a degree of epoxidation of 25% are shown in Table 5. The tensile strength retention and elongation at break of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com