Flame retardant high-wood content wood-plastic composite material and preparation method thereof

A technology of wood-plastic composite material and wood fiber material, which is applied in the field of wood-plastic composite material and its preparation, can solve the problems of high cost, low flame retardant efficiency, and easy-to-burn flame retardant addition, and achieve low cost and good The effect of mechanical properties and good synergistic flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

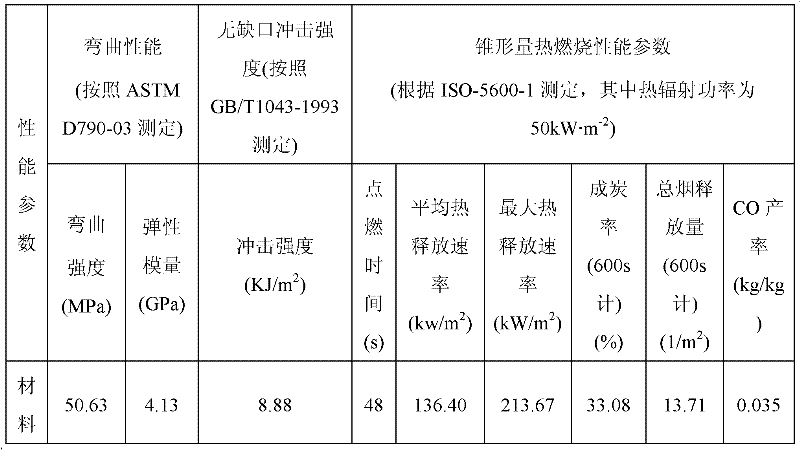

Examples

specific Embodiment approach 1

[0012]Specific Embodiment 1: In this embodiment, the flame-retardant high-wood content wood-plastic composite material consists of 5-25 parts by weight of wood fiber flame retardant, 50-70 parts of wood fiber material, 30-50 parts of Thermoplastics, 5-25 parts of flame retardant for plastics, 2-8 parts of coupling agent, 1-3 parts of lubricant, 0.1-3 parts of antioxidant, 1-5 parts of smoke suppressant and 0 ~5 parts of additives; among them, the flame retardants for wood fiber are amidinourea phosphate, flame retardant FRW, hydroxymethylated amidinourea phosphate, ammonium polyphosphate, ammonium pyrophosphate, ammonium monohydrogen phosphate, phosphoric acid Ammonium dihydrogen, ammonium sulfate, melamine or melamine pyrophosphate; the lignocellulosic material is one or a mixture of wood flour, rice husk powder, bamboo chips, straw powder, fruit shell powder, bagasse, and hemp fiber; Thermoplastics are polyethylene, polypropylene, polyethylene recycled materials or polypropy...

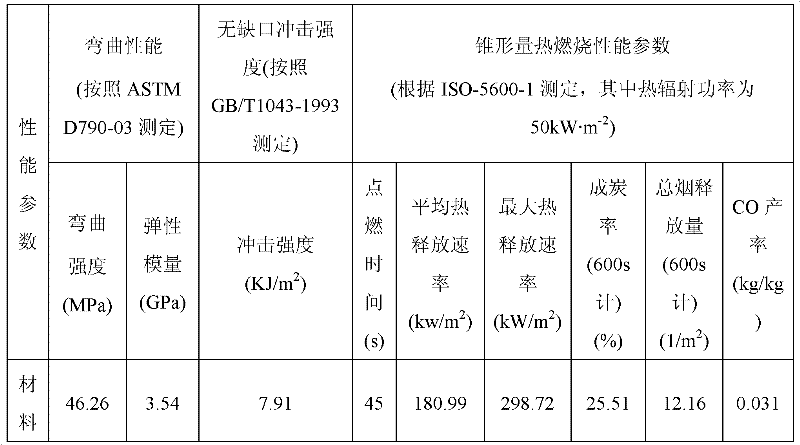

specific Embodiment approach 2

[0014] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the flame-retardant high-wood-content wood-plastic composite material consists of 5 parts of wood fiber flame retardant, 50 parts of wood fiber material, and 50 parts by weight. 1 part of thermoplastic, 5 parts of plastic flame retardant, 2 parts of coupling agent, 1 part of lubricant, 0.1 part of antioxidant and 1 part of smoke suppressant. Others are the same as in the first embodiment.

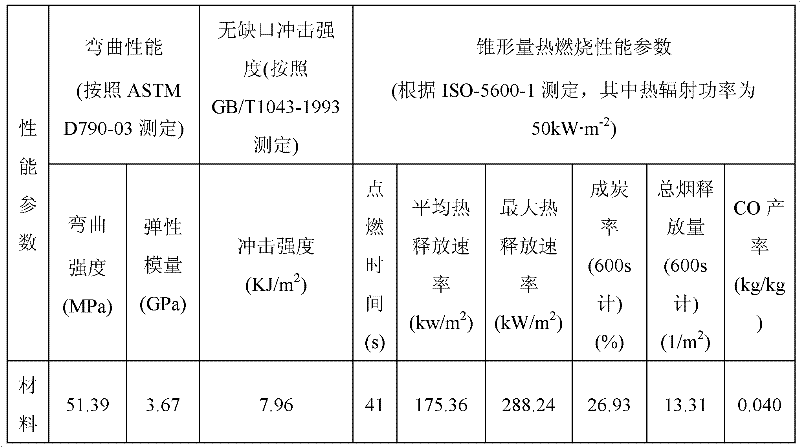

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the flame-retardant high-wood-content wood-plastic composite material consists of 25 parts by weight of a wood fiber flame retardant, 70 parts of a wood fiber material, and 30 parts by weight. 25 parts of thermoplastic, 25 parts of plastic flame retardant, 8 parts of coupling agent, 3 parts of lubricant, 3 parts of antioxidant, 5 parts of smoke suppressant and 5 parts of additives. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com