Method for modifying and dying polyamide (PA) fabric by use of titanium sulfate and urea as well as reactive dye

A technology of titanium sulfate and nylon, which is applied in the modification and dyeing of nylon fabrics, and in the field of nylon fabric modification and dyeing. It can solve the problem that nano-titanium dioxide loading and dyeing cannot be realized simultaneously, and nylon fabrics have low anti-ultraviolet and antibacterial properties, fabric feel and breathability. Poor performance and other problems, to achieve the effect of excellent color fastness to sunlight, saving raw materials, and high dyeing percentage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

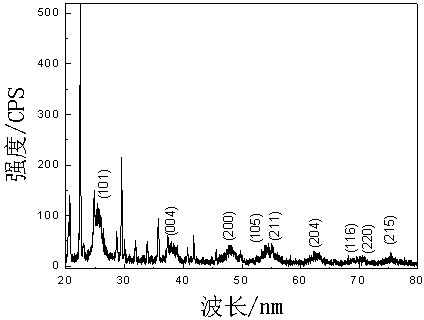

Image

Examples

Embodiment 1

[0028] Weigh 5g of nylon fabric and 15g of titanium sulfate, weigh urea according to the molar ratio of titanium sulfate to urea of 0.1:1, and weigh reactive brilliant blue KN-R dye according to 0.3% of the mass of nylon fabric. Nylon fabrics were washed with a mixed solution of deionized water and absolute ethanol with a volume ratio of 1:1 at a temperature of 80 ° C for 30 min under ultrasonic vibration at 50 KHz and a power of 100 W, and dried at 60 ° C. Dissolve the weighed titanium sulfate, urea and dye in 50ml deionized water, then immerse the nylon fabric in the mixed solution of titanium sulfate, urea and dye for 10min, then add the titanium sulfate, urea and dye solution impregnated with nylon fabric into a high-temperature and high-pressure reactor, and filled with deionized water to 60% of the volume of the reactor, and the sealed reactor was subjected to constant temperature treatment at 120°C for 3 hours. After the reaction, take out the nylon fabric, use 2g / L s...

Embodiment 2

[0031] Weigh 5g of nylon fabric and 30g of titanium sulfate, weigh urea according to the molar ratio of titanium sulfate to urea of 0.5:1, and weigh reactive brilliant blue KN-R dye according to 2% of the mass of nylon fabric. Nylon fabrics were washed with a mixed solution of deionized water and absolute ethanol with a volume ratio of 1:1 at a temperature of 80 ° C for 30 min under ultrasonic vibration at 50 KHz and a power of 100 W, and dried at 60 ° C. Dissolve the weighed titanium sulfate, urea and dye in 50ml deionized water, then immerse the nylon fabric in the mixed solution of titanium sulfate, urea and dye for 30min, then add the titanium sulfate, urea and dye solution impregnated with nylon fabric into a high-temperature and high-pressure reactor, and filled with deionized water to 80% of the volume of the reactor, and the sealed reactor was treated at a constant temperature of 160°C for 1 hour. After the reaction, take out the nylon fabric, use 2g / L soap flakes, 2...

Embodiment 3

[0034] Weigh 5g of nylon fabric and 20g of titanium sulfate, weigh urea according to the molar ratio of titanium sulfate to urea of 0.3:1, and weigh reactive brilliant blue KN-R dye according to 1% of the mass of nylon fabric. Nylon fabrics were washed with a mixed solution of deionized water and absolute ethanol with a volume ratio of 1:1 at a temperature of 80 ° C for 30 min under ultrasonic vibration at 50 KHz and a power of 100 W, and dried at 60 ° C. Dissolve the weighed titanium sulfate, urea and dye in 50ml deionized water, then immerse the nylon fabric in the mixed solution of titanium sulfate, urea and dye for 20min, then add the titanium sulfate, urea and dye solution impregnated with nylon fabric into a high-temperature and high-pressure reactor, and filled with deionized water to 70% of the volume of the reactor, and the sealed reactor was treated at a constant temperature of 140°C for 1.5h. After the reaction, take out the nylon fabric, use 2g / L soap flakes, 2g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com