Formula whey milk

A technology of formula milk and whey, applied in whey, dairy products, applications, etc., can solve problems such as inability to adapt to the digestive system, difficulty in calculating the concentration of milk powder accurately, indigestion of infants, etc., and achieve short storage time, low cost, and high-quality products The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

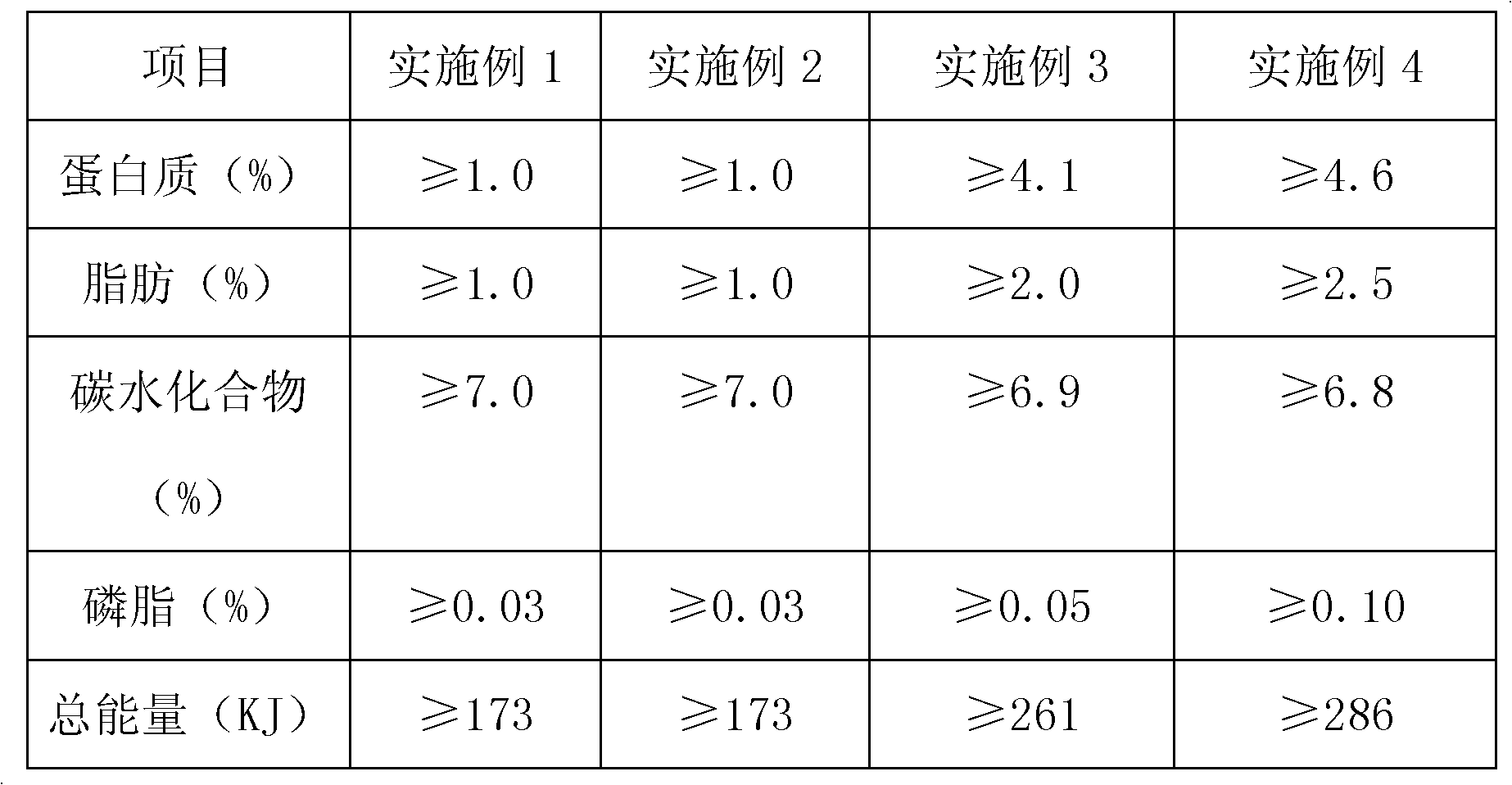

Examples

preparation example Construction

[0026] The preparation method adopted by the formula whey milk of the present invention is two kinds of prior art pasteurization process and ultra-high temperature instantaneous sterilization process UHT.

[0027] The formula whey milk of the present invention has components close to human milk, and its fat composition is better than that of human milk. The ratio of oleic acid: linoleic acid: linolenic acid is 1:1:1, and in human milk, saturated fatty acids account for about 50%.

[0028] The formula whey milk of the present invention does not need to be reconstituted, so the concentration remains unchanged, and the digestive system diseases of infants can be reduced or avoided. At the same time, feeding is also convenient. Since it does not need to be dissolved in boiling water, it can be fed at 20-30°C, so the feeding concentration will not be increased due to the growth of infants and young children. The feeding frequency or feeding amount can be adjusted according to the ph...

Embodiment 1

[0031] Embodiment 1, mass ratio group is:

[0032] 1. Whey 88.98%

[0033] 2. Raw milk 10.0%

[0034] 3. Vegetable oil 1.0%

[0035] 4. Phospholipids 0.02%

[0036] At room temperature, take the above-mentioned raw materials from the stainless steel storage tank, and input them into the batching tank through the pump pipeline for mixing, and process according to the pasteurization process of the prior art. In the clean area, the carton is 236ml, and the plastic cup is 150-200ml , 200ml glass bottles for aseptic filling.

Embodiment 2

[0037] Embodiment 2, mass ratio component:

[0038] 1. Whey 88.98%

[0039] 2. Raw milk 10.0%

[0040] 3. Vegetable oil 1.0%,

[0041] 4. Phospholipids 0.02%.

[0042] At room temperature, take the above-mentioned raw materials from the stainless steel storage tank, and input them into the batching tank through the pump pipeline to mix them, and process them according to the existing technology ultra-high temperature instantaneous sterilization UHT process, according to the carton 236ml, plastic cup 150 ~ 200ml, 200ml glass bottle for aseptic filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com