Production method of fire retardant type magnesium hydroxide

A technology of magnesium hydroxide and a production method, applied in directions such as magnesium hydroxide, can solve the problems of unrealized industrialization, poor compatibility with high polymers, reduced processing performance and product quality, etc., and achieves good gas-liquid mixing effect, The effect of low temperature and pressure conditions and concentrated particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

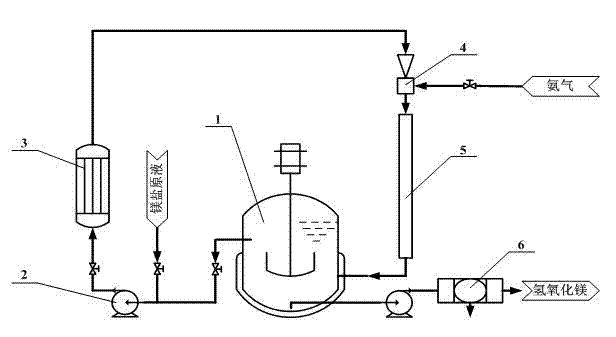

Method used

Image

Examples

Embodiment 1

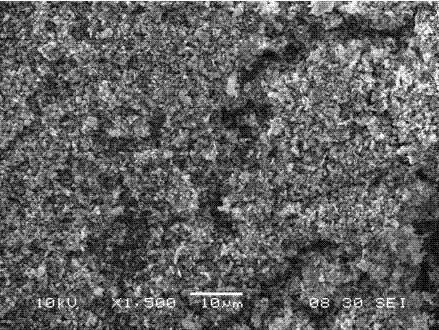

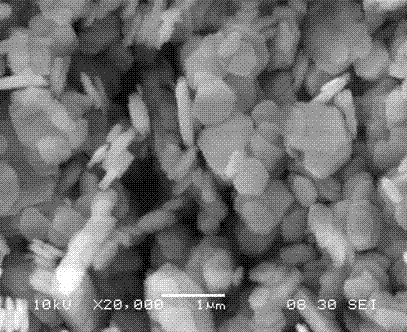

[0045] Magnesium nitrate refined solution (magnesium ion concentration 1.25mol / L, ammonium ion concentration 0.15mol / L) was obtained by distilling ammonium nitrate from lightly burned powder (containing 87wt% magnesium oxide, 92% magnesium oxide activity) and ammonium nitrate. Invent the steps and conditions of the above-mentioned specific embodiment to complete the production of magnesium hydroxide products. The temperature of the solution in the reactor is 130° C., and the concentration of magnesium ions in the product slurry is 0.45 mol / L. Characterization of product particle properties such as Figure 2-5 .

Embodiment 2

[0047] Magnesium chloride refined liquid (magnesium ion concentration 1.40mol / L, ammonium ion concentration 0.10mol / L) is obtained by distilling ammonium chloride from lightly burned powder (containing 87wt% magnesium oxide, 92% magnesium oxide activity) and ammonium chloride. Invent the steps and conditions of the above-mentioned specific embodiment to complete the production of magnesium hydroxide products. The temperature of the solution in the reactor is 130° C., and the concentration of magnesium ions in the product slurry is 0.30 mol / L. Characterization of product particle properties such as Figure 6-9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com