Method for purifying chromatographic grade butyl acetate

A technology of butyl acetate and a purification method, which is applied in the field of purification of chromatographic grade butyl acetate, and achieves the effects of simple method, easy separation, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A purification method of chromatographic grade butyl acetate, the steps are as follows:

[0026] (1) Lift the raw material butyl acetate (99.0% content) to the top of the adsorption column, where the adsorption column is 1.6M in height, 4.2cm in diameter, and contains activated carbon with a particle size of about 20 mesh to 80 mesh and active oxidation of 50 mesh to 100 mesh Aluminum adsorbent, the column capacity is 4 / 5 of the column height, and the raw material flows through two series-connected adsorption columns at a speed of 50mL / min for adsorption and removal of impurities;

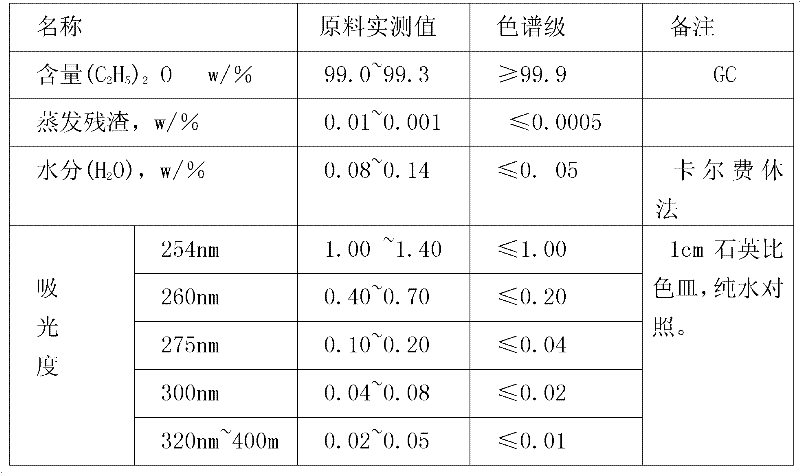

[0027] In the column, butyl acetate is in full contact with activated carbon and activated alumina adsorbents to remove organic impurities by adsorption, and detect the quality of the adsorbed effluent. Its specific technical index requirements are shown in Table 1) and then enter the next step operation, and remove the fraction before adsorption with high impurity.

[0028] (2) Enter the e...

Embodiment 2

[0033] A kind of purification method of chromatographic grade butyl acetate for scientific research, the steps are as follows:

[0034] (1) Lift the raw material butyl acetate (99.0% content) to the top of the adsorption column. The adsorption column is 1.6M in height and 4.2cm in diameter. Aluminum adsorbent, the column capacity is 4 / 5 of the column height, and the raw material flows through two series-connected adsorption columns at a speed of about 100mL / min for adsorption and removal of impurities;

[0035] In the column, butyl acetate is in full contact with activated carbon and activated alumina adsorbents to remove organic impurities by adsorption, and detect the quality of the adsorbed effluent. Its specific technical index requirements are shown in Table 1) and then enter the next step operation, and remove the fraction before adsorption with high impurity.

[0036] (2) Put the effluent in step (1) into the drying column. The specifications and loading capacity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com