Industrial method for producing iminodibenzyl from 2,2'-ethylenedianiline by catalytic deamination

A technology of diaminobibenzyl catalyzed deamination reaction and iminodibenzyl, applied in chemical industry, organic chemistry, sustainable manufacturing/processing, etc., can solve serious decomposition of raw materials and products, no proposed production process, and short catalyst life and other problems to achieve the effect of improving life, improving reaction performance and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

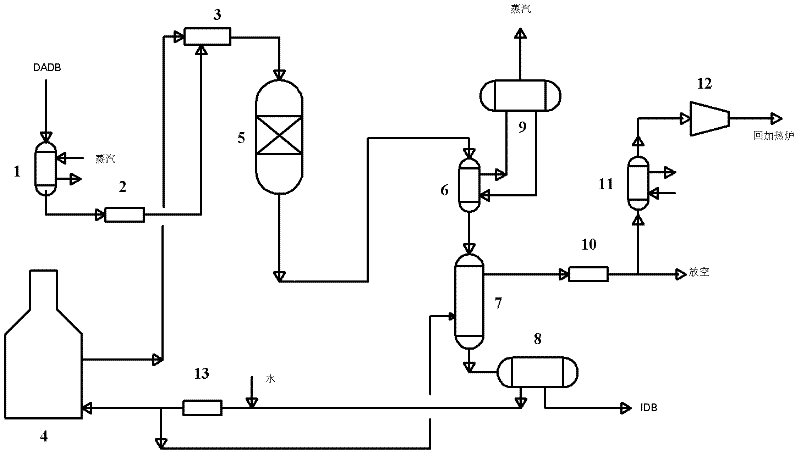

[0033] Catalytic gas-phase deamination of 2,2′-diaminobibenzyl to produce iminodibenzyl figure 1 The process flow is carried out, the deamination reactor 5 is a thin-bed axial reactor type, the mol ratio of water vapor to 2,2'-diaminobibenzyl gas is 300, and the temperature of the reactant stream at the inlet of the reaction bed is The temperature is 420°C, the average absolute pressure in the reactor is 0.30MPa, the deamination catalyst is γ-alumina catalyst, and the weight space velocity of 2,2′-diaminobibenzyl is 0.07h -1 . The temperature of the reaction product from the waste heat boiler 6 is controlled at 130° C., and then enters the liquid-vapor separation tank 7 . In the liquid-vapor separation tank 7, the liquid reaction product is separated from the water vapor, and the liquid reaction product falls into the lower part of the liquid-vapor separation tank 7 to crystallize out, and enters the liquid-solid separation tank from the lower part of the liquid-vapor separat...

Embodiment 2

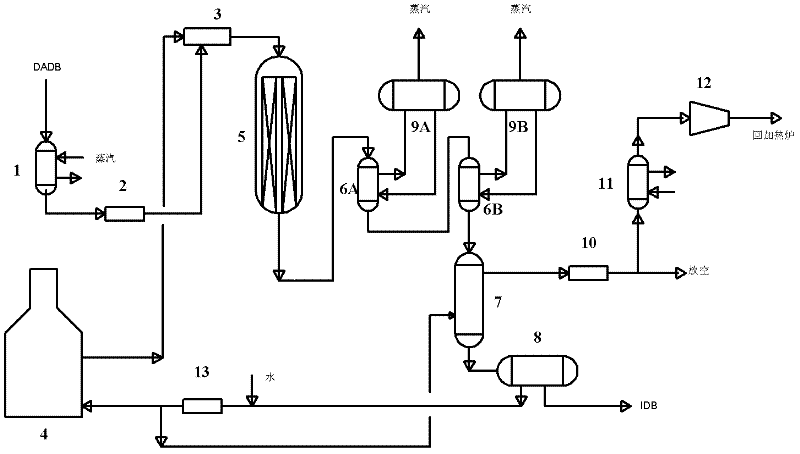

[0035] Catalytic gas-phase deamination of 2,2′-diaminobibenzyl to produce iminodibenzyl figure 1 The process flow is carried out, the deamination reactor 5 is a radial reactor type, the mol ratio of water vapor to 2,2'-diaminobibenzyl gas is 400, and the temperature of the reactant flow at the inlet of the reaction bed is 400 ° C, The average absolute pressure in the reactor is 0.25MPa, the deamination catalyst uses γ-alumina catalyst, and the weight space velocity of 2,2'-diaminobibenzyl is 0.02h -1 . The temperature of the reaction product from the primary waste heat boiler 6A is controlled at 220°C, the temperature of the reactant flow from the secondary waste heat boiler 6B is controlled at 120°C, and then enters the liquid-vapor separation tank 7. In the liquid-vapor separation tank 7, the liquid reaction product is separated from the water vapor, and the liquid reaction product falls into the lower part of the liquid-vapor separation tank 7 to crystallize out, and enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com