Preparation method of mesoporous tomato stem active carbon

A tomato, multi-mesoporous technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of incompetent industrial utilization, large amount of activator, low activation efficiency, etc., to achieve developed pores, more mesopores, and activated Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Wash the tomato stalks with water, dry them at 100°C, pulverize them with a plant pulverizer, pass through a 45-mesh sieve, and set aside;

[0024] (2) According to the mass ratio of tomato sticks: H 4 P 2 o 7 = 1:1, H 4 P 2 o 7 Add to the tomato stalk scraps processed in step (1), stir while adding, after ultrasonic treatment for 15min, let stand at room temperature for 8h to obtain a mixture;

[0025] (3) Put the mixture treated in step (2) in a muffle furnace, heat up to 500°C, carbonize for 1 hour, stop heating, cool to room temperature, take out the solid material, wash with deionized water to a pH value of 6.5, and bake Dry, multi-mesoporous tomato stalk activated carbon.

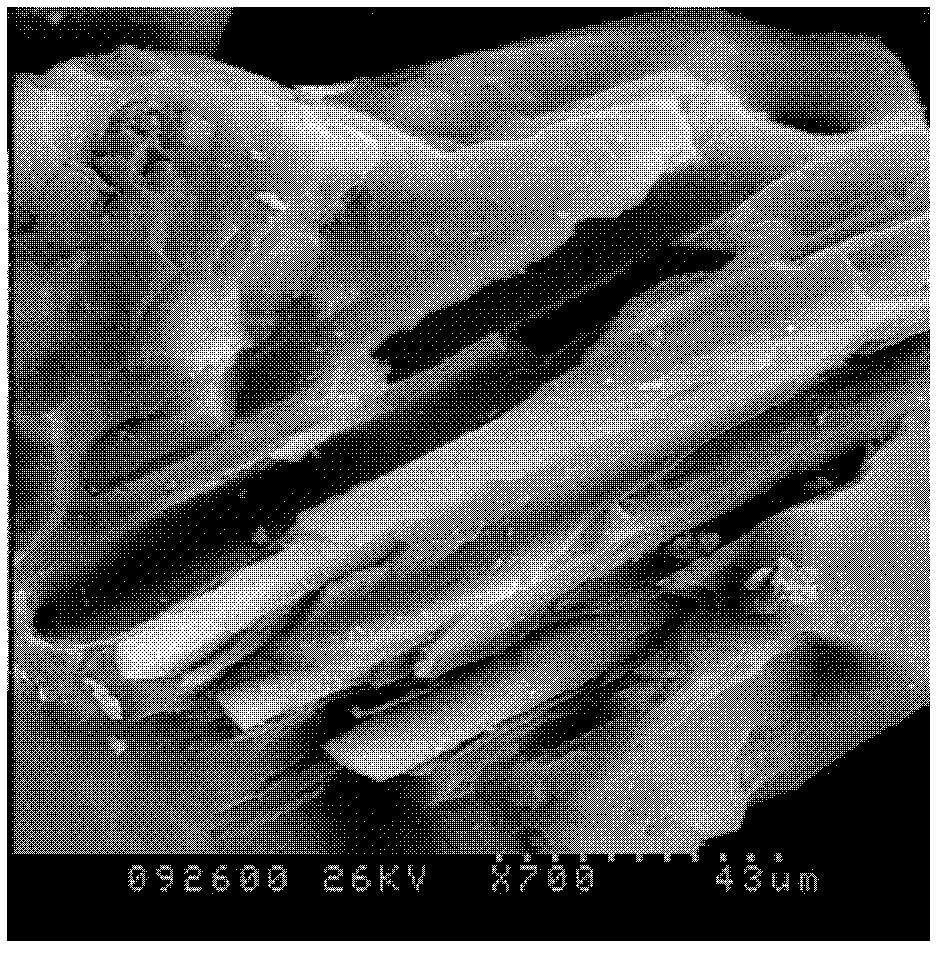

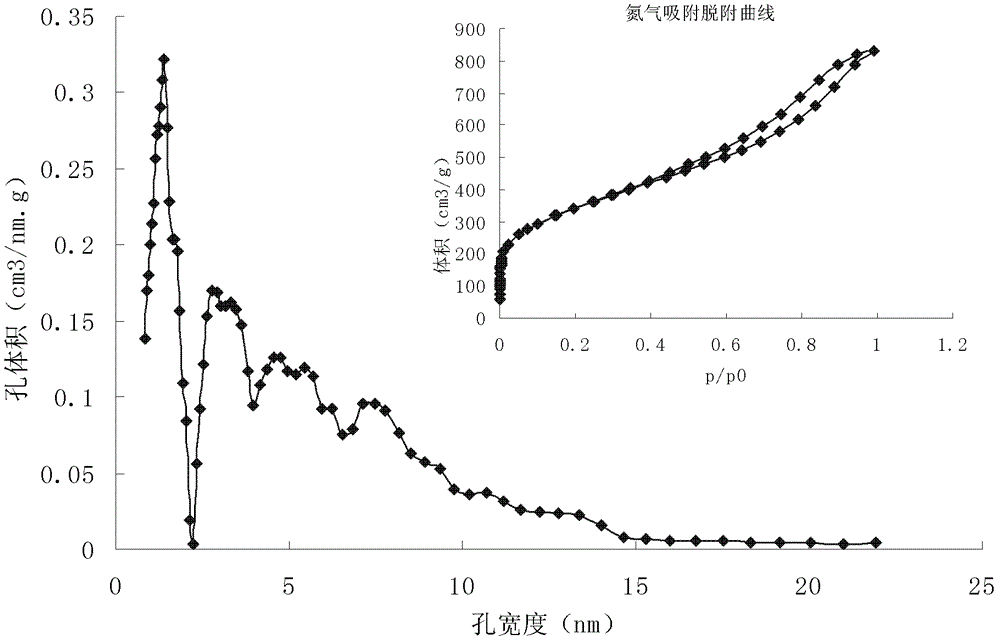

[0026] Gained tomato stalk activated carbon electron microscope photo is as follows figure 1 As shown, the pore size distribution and N 2 The adsorption-desorption curve is as figure 2 It can be seen from the results that the prepared activated carbon is completely activated, has ...

Embodiment 2

[0028] (1) Wash the tomato stalks with water, dry them at 80° C., pulverize them with a plant pulverizer, pass through a 45-mesh sieve, and set aside;

[0029] (2) According to the mass ratio of tomato sticks: H 4 P 2 o 7 =1:0.75, H 4 P 2 o 7 Adding it to the crushed tomato stalks processed in step (1), mixing evenly, heating the mixture in a water bath at 90°C for 18 minutes, and standing it at room temperature for 8 hours to obtain the mixture;

[0030] (3) Put the mixture treated in step (2) in a muffle furnace, heat up to 450°C, carbonize for 1.5h, stop heating, cool to room temperature, take out the solid material, wash with deionized water until the pH value is 7.0, Dry naturally, that is, multi-mesoporous tomato stem activated carbon.

Embodiment 3

[0032] (1) Wash the tomato stalks with water, dry them at 90° C., pulverize them with a plant pulverizer, pass through a 45-mesh sieve, and set aside;

[0033] (2) According to the mass ratio of tomato sticks: H 4 P 2 o 7 =1:0.9, H 4 P 2 o 7 Adding to the crushed tomato stalks processed in step (1), stirring while adding, after ultrasonic treatment for 18min, standing for 7.5h to obtain a mixture;

[0034] (3) Put the mixture treated in step (2) in a muffle furnace, heat up to 500°C, carbonize for 1 hour, stop heating, cool to room temperature, take out the solid material, wash with deionized water to a pH value of 6.5, and bake Dry or air-dried, that is, multi-mesoporous tomato stalk activated carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com