Method for preparing biologically active titanium dioxide film on NiTi alloy surface

A titanium oxide film, bioactive technology, applied in the field of surface bioactivation, can solve problems such as harsh conditions, achieve good biocompatibility, simplify the process, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

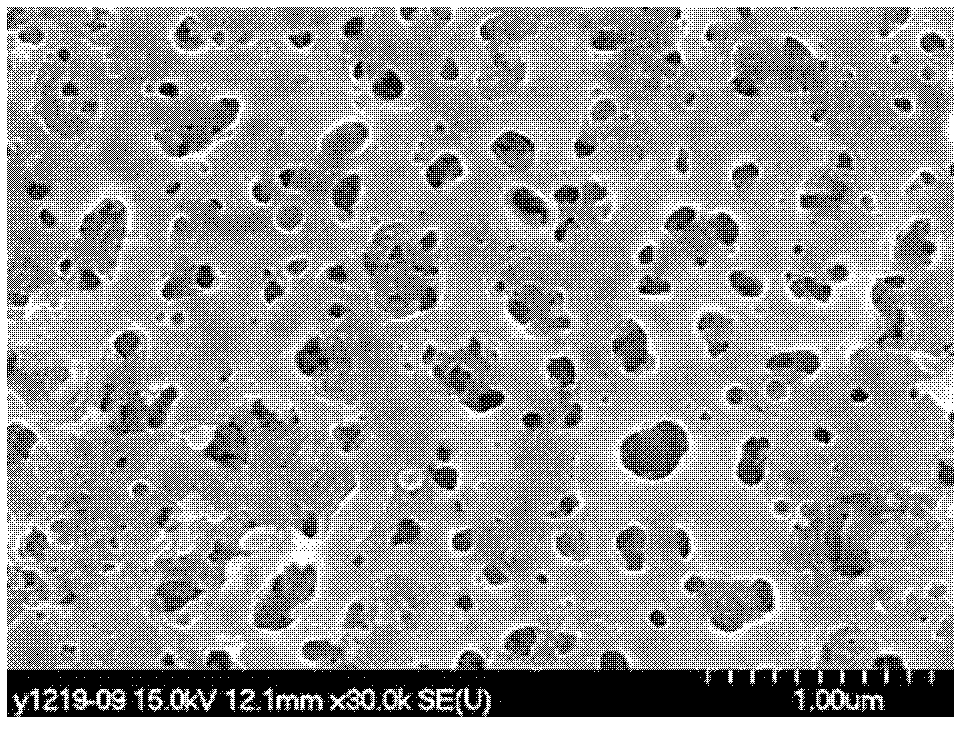

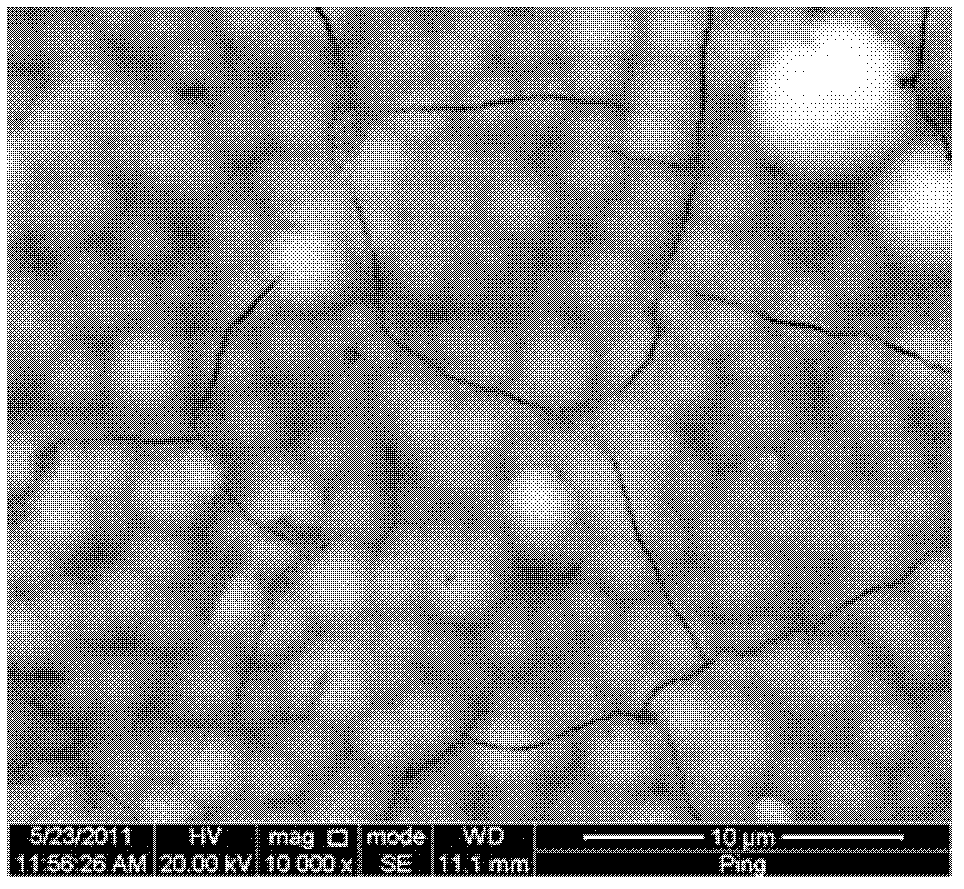

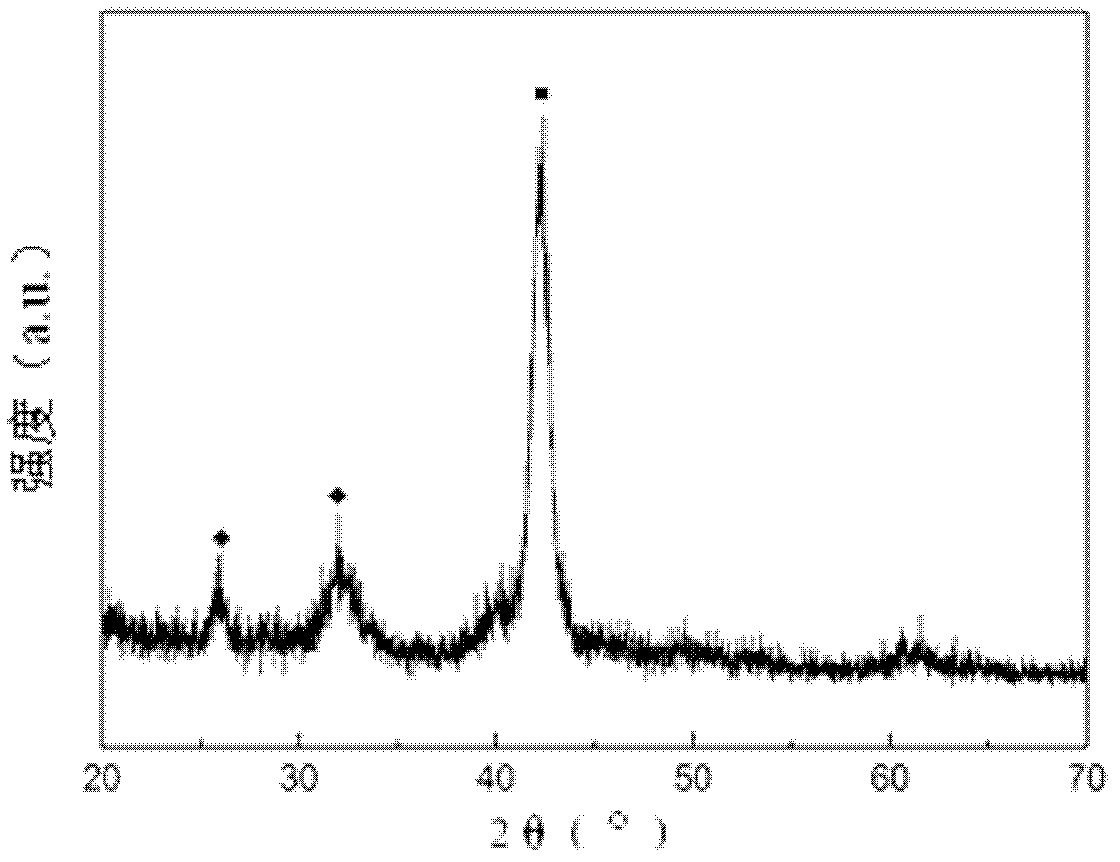

[0013] Specific embodiment one: the preparation method of the bioactive titanium oxide film layer on the surface of the NiTi alloy of the present embodiment is carried out according to the following steps: the concentrated sulfuric acid with a mass concentration of 98% is used as the electrolyte, the NiTi alloy is used as the positive electrode, and the stainless steel tank is used as the negative electrode. When the electrolyte temperature is 0℃~10℃, the current density is 1A / dm 2 ~20A / dm 2 1. Micro-arc oxidation under the condition of a voltage of 50V-70V for 2min-10min to obtain a biologically active titanium oxide film on the surface of the NiTi alloy.

[0014] In this embodiment, concentrated sulfuric acid with strong passivation is used as electrolyte to carry out micro-arc oxidation on NiTi alloy, and the pre-passivation layer formed on the surface of NiTi alloy by concentrated sulfuric acid is an important condition for determining whether the later spark discharge can...

specific Embodiment approach 2

[0015] Specific embodiment 2: This embodiment differs from specific embodiment 1 in that the NiTi alloy is used as the positive electrode and the stainless steel tank is used as the negative electrode. The temperature of the electrolyte is 2°C to 8°C, and the current density is 5A / dm. 2 ~18A / dm 2 , Micro-arc oxidation under the condition of voltage 55V~65V for 3min~8min. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment is different from Embodiment 1 in that the NiTi alloy is used as the positive electrode and the stainless steel tank is used as the negative electrode. The temperature of the electrolyte is 4°C and the current density is 12A / dm. 2 , Micro-arc oxidation under the condition of voltage 60V for 6min. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com