Method for preparing double-electric-layer capacitor

An electric double-layer capacitor and electrode technology, which is applied in the field of super-capacity electric double-layer capacitor preparation, can solve problems such as affecting capacitor performance, wide pore size distribution, affecting service life, etc., and achieves improved microstructure and performance, high charge and discharge speed, The effect of large specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

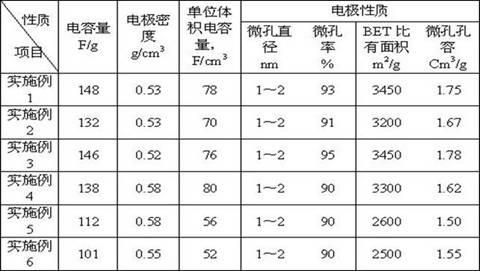

Examples

Embodiment 1

[0032] Take 100g petroleum coke, use 200gKOH, 5gCa(OH) 2 The solid mixture is used as a compound activator. After mixing, it is pre-activated in a low-temperature activation furnace for about 2 hours under nitrogen protection. The activation temperature is 200°C. The material is then transferred to a high-temperature activation furnace and activated at 750°C for about 1 hour. After activation, the material is taken out. And washed with water to neutral (PH=7), then soaked in dilute hydrochloric acid with a concentration of 0.014mol / L for about 30 minutes, and finally dried at 100°C and 0.092MPa vacuum for 2 hours to obtain powder activated carbon.

[0033] Take 2g of graphite and 5g of polytetrafluoroethylene and add it to the above-mentioned powdered activated carbon, press it with a 50-mesh stainless steel mesh at 80MPa and 150°C to make it 0.5mm thick and 5cm in area. 3 1 activated carbon electrode. The stainless steel mesh is pressed in the middle of the carbon electrode ...

Embodiment 2

[0036] Take 100g petroleum coke powder, use 300gKOH, 10gCa(OH) 2 , 5gZnCL 2The solid mixture is used as a complex activator. After mixing, activate in a low-temperature activation furnace for 2.5 hours at a temperature of 150°C, then transfer to a high-temperature activation furnace and activate at 800°C for 0.5 hours. Soak in L dilute hydrochloric acid for about 30 minutes, and finally dry at 120°C and 0.092MPa vacuum for 2 hours to obtain powdered activated carbon.

[0037] Add 15g of carbon black and 60g of coal tar to the above-mentioned powdered activated carbon, and press it with 200-mesh stainless steel mesh at 100MPa and 140°C to make it 0.4mm thick and 6cm in area. 3 1 activated carbon electrode. The stainless steel mesh is pressed in the middle of the carbon electrode and integrated with the electrode. The other electrode is pressed on a stainless steel mesh with one of ruthenium oxide, manganese oxide, and nickel oxide, and cut into a sheet with a thickness of a...

Embodiment 3

[0040] Take 100g lignin, use 300gKOH, 2g Ca(OH) 2 , 10g MaOH solid mixture as composite activator. After mixing, put it in the low-temperature activation furnace for about 1.5 hours, the activation temperature is 550°C, then transfer to the high-temperature activation furnace, and activate it at 700°C for about 1 hour. After activation, the material is taken out and washed with water until neutral, then soaked in 0.01 mol / L dilute hydrochloric acid for 30 minutes, and finally dried at 100°C and 0.092MPa vacuum for 2 hours to obtain powdered activated carbon.

[0041] Add 15g of polyaniline (PAn) and 60g of polytetrafluoroethylene (PTFE) into the above-mentioned powdered activated carbon, press it with 200 mesh stainless steel mesh in the middle of the carbon at 90MPa and 140°C, and integrate with the electrode.

[0042] Put the two above-mentioned activated carbon electrodes into 5wt% KOH aqueous solution, and add a separator in the middle to form an electric double layer cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com