Feed for specific pathogen-free (SPF) chicken in peak laying period and preparation method for feed

A technology for egg production peak period and feed, applied in animal feed, food preparation, animal feed and other directions, can solve the problems of shortening of feed storage time, loss of nutrients, waste of resources, etc., and achieve scientific and reasonable feed formula, easy storage, satisfying The effect of nutritional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take each raw material respectively by weight part according to the present invention: 633kg corn flour, 200kg soybean meal, 20kg wheat bran, 40kg fish meal, 1.8kg content are 98% methionine, 80kg stone powder, 12.2kg calcium hydrogen phosphate, 3kg salt and 10kg of premix, wherein every kilogram of said premix contains 20g of compound multidimensional, 200g of compound mineral dimension, 200g of choline chloride, 400g of imported fish meal and 180g of 200 mesh zeolite powder.

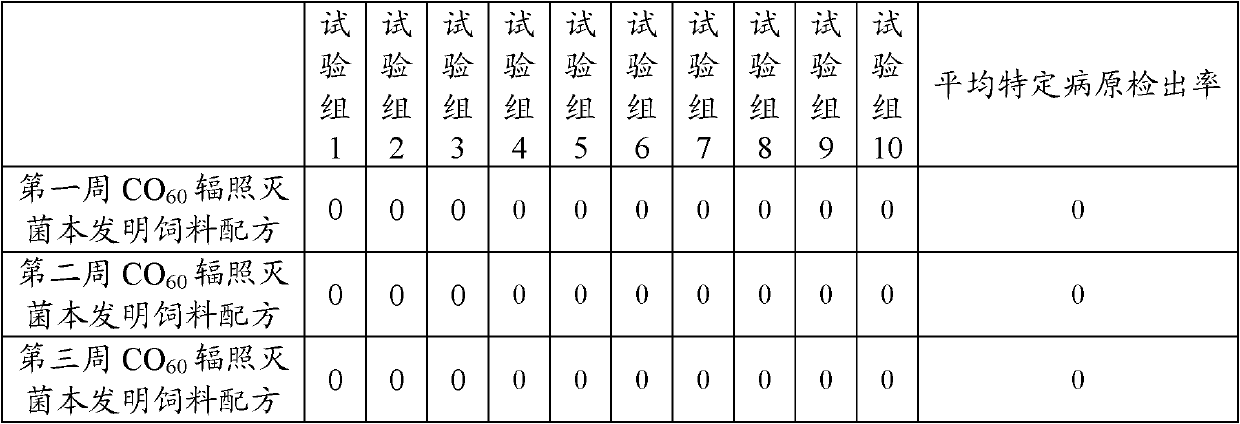

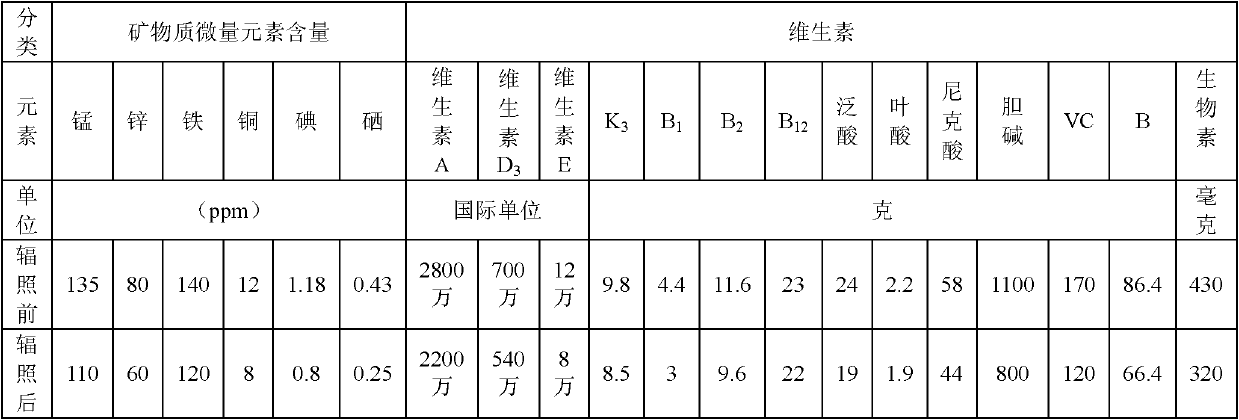

[0028] Grind and mix the raw materials of the above weight evenly, and use nylon-polyethylene composite packaging material to seal the package, each bag is 40KG, and the volume is 80cm*40cm*20cm, using Co 60 The ray source is sterilized by irradiation, the calibration error of the irradiation field is less than ±5%, the unevenness of the absorbed dose of the sample is less than 1.2, when the sample is irradiated to half the dose, the irradiation is continued after being turned over in situ, and t...

Embodiment 2

[0030] Take by weighing each raw material respectively by weight part according to the present invention: 625kg corn flour, 200kg soybean meal, 15kg wheat bran, 45kg fishmeal, 2kg content are 98% methionine, 90kg stone powder, 10kg calcium hydrogen phosphate, 2.5kg table salt and 10kg Premix, wherein every kilogram of said premix contains 20g of compound multidimensional, 200g of compound mineral dimension, 200g of choline chloride, 400g of imported fish meal and 180g of 200 mesh zeolite powder.

[0031]Grind and mix the raw materials of the above weight evenly, and use nylon-polyethylene composite packaging material to seal the package, each bag is 40KG, and the volume is 80cm*40cm*20cm, using Co 60 The ray source is sterilized by irradiation, the calibration error of the irradiation field is less than ±5%, the unevenness of the absorbed dose of the sample is less than 1.2, when the sample is irradiated to half the dose, the irradiation is continued after being turned over in ...

Embodiment 3

[0033] Take by weighing each raw material respectively by weight part according to the present invention: 640kg corn flour, 210kg soybean meal, 20kg wheat bran, 35kg fish meal, 1kg content are 98% methionine, 70kg stone powder, 11kg calcium hydrogen phosphate, 2.5kg table salt and 10kg Premix, wherein every kilogram of said premix contains 20g of compound multidimensional, 200g of compound mineral dimension, 200g of choline chloride, 400g of imported fish meal and 180g of 200 mesh zeolite powder.

[0034] Grind and mix the raw materials of the above weight evenly, and use nylon-polyethylene composite packaging material to seal the package, each bag is 40KG, and the volume is 80cm*40cm*20cm, using Co 60 The ray source is sterilized by irradiation, the calibration error of the irradiation field is less than ±5%, the unevenness of the absorbed dose of the sample is less than 1.2, when the sample is irradiated to half the dose, the irradiation is continued after being turned over i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com