Sugar liquid evaporator with sharp expansion and accelerated flow converging-diverging tubes inserted with twisted leaves

A swirling sheet and evaporator technology, which is applied in the field of evaporators to enhance heat transfer, can solve the problems of large differences in sugar liquid concentration and viscosity distribution, slow fluid velocity near the wall, low heat transfer coefficient, etc., and achieve strong heat transfer. The effect of field synergy, reducing wall scaling and improving convective heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

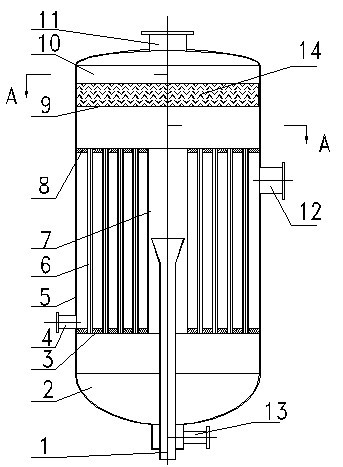

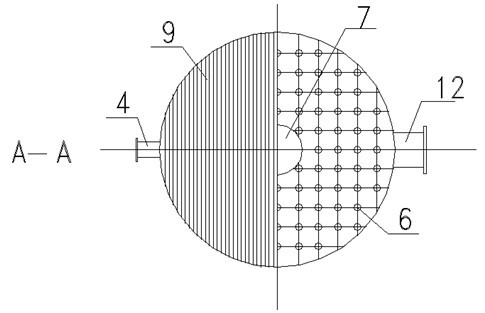

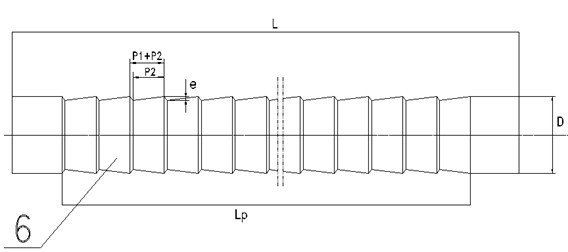

[0029] The structure of the sugar liquid evaporator in this embodiment is as shown above. The cylinder body 5 is made of 304 stainless steel, with a diameter of Φ2000x16mm and a height of 2000mm. There are 1170 internally inserted swirl slice rapid expansion and acceleration flow zoom tubes 6 in the cylinder body 5 (the front view of which is shown in image 3 shown). The tube body is made of 304 stainless steel, the tube length is 2000mm, and the tube diameter D is Φ45x3mm. The ratio of the length P2 of the contraction section to the length P1 of the expansion section is 8:1, and the periodic rib spacing (P1+P2) is 10 times the rib depth e , The rib depth e is 8% of the pipe diameter D, arranged in a square along the cylinder, the pipe spacing is 58mm, the diameter of the downcomer 7 in the axial center area is Φ250x10mm, and the length is 2000mm. The rapid expansion of the inserted swirl sheet and the rapid expansion of the accelerated flow zoom tube 6 and the downcomer 7 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com