Preparation method of organosilicon hollow microsphere

A technology of hollow microspheres and organosilicon, which is applied in the field of preparation of organosilicon hollow microspheres, can solve the problems of complex process, high preparation cost, and unsuitability for mass production, and achieve simple preparation process, reduced preparation cost, and good formability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

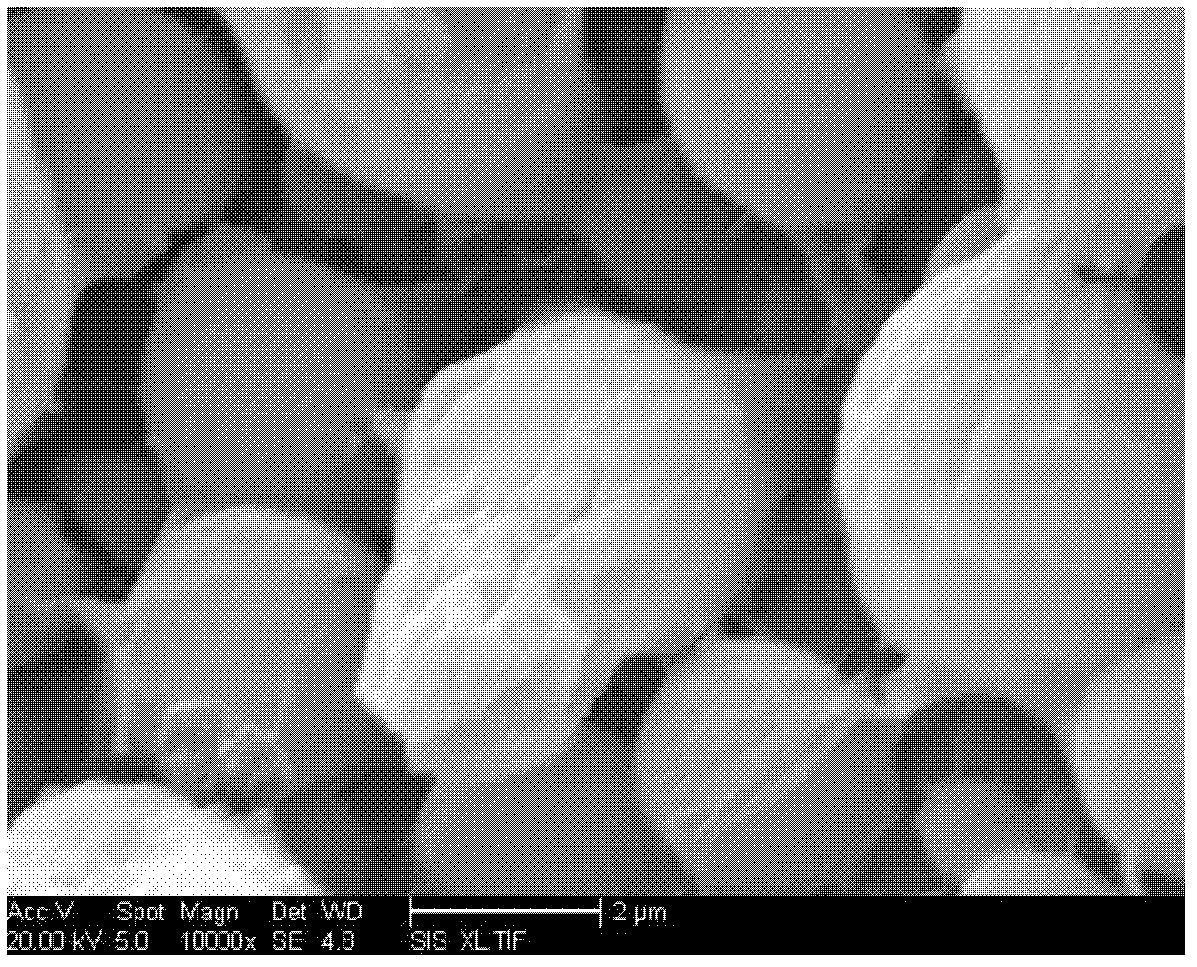

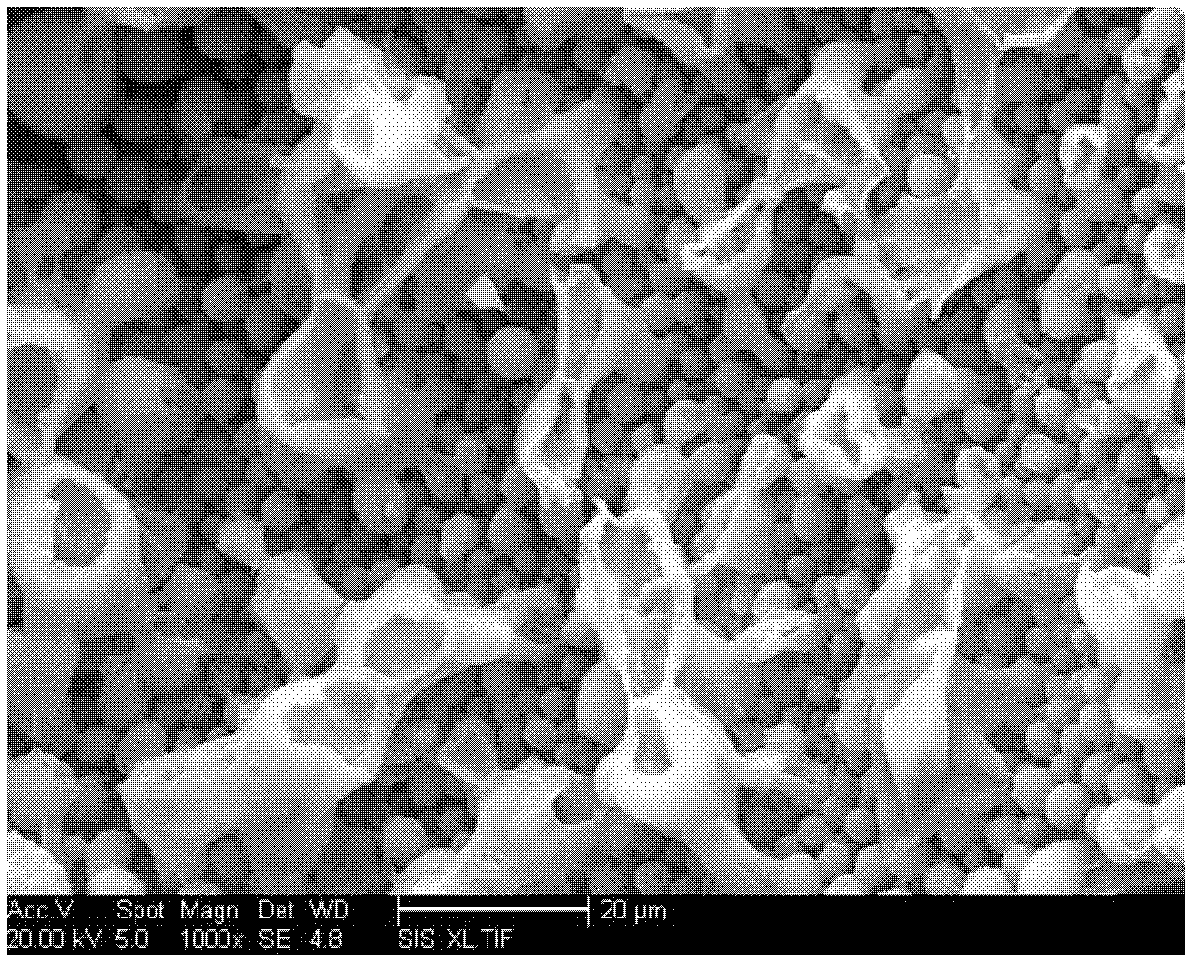

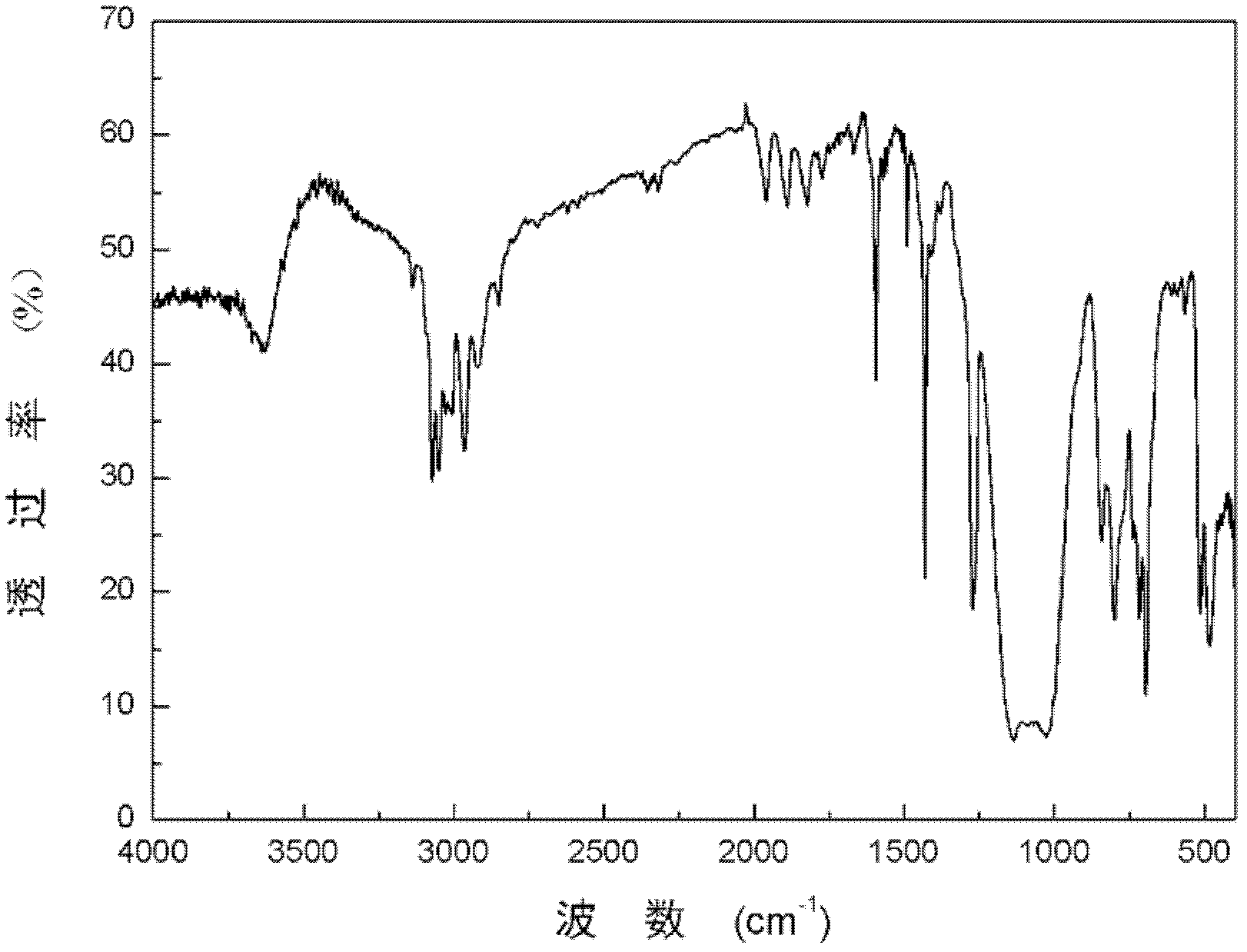

[0009] Specific embodiment 1: the preparation method of a kind of organosilicon hollow microsphere of the present embodiment is completed according to the following steps:

[0010] 1. Ultrasonic dispersion: use water as a solvent to prepare the surfactant into an aqueous surfactant solution; then add the silicone resin solution, and ultrasonically disperse it at 80kHz to 120kHz for 2 to 10min to obtain a uniformly mixed milky white mixture; 2. Adjust the pH value : Add alkaline solution to the milky white mixed solution prepared in step 1 at 200 to 300 rpm to obtain a mixed solution with a pH value of 9 to 11, and continue stirring for 5 to 10 min at 200 to 300 rpm to obtain a uniform mixed solution; 3. Forming: Seal the reaction vessel with the homogeneous mixture prepared in step 2 at 500-600 rpm, and heat it in a water bath at 50-80°C for 8-24 hours to obtain crude organosilicon hollow microspheres, which are then centrifuged and washed once with an organic solvent , and fi...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the surfactants described in step 1 are sodium dodecylbenzenesulfonate, sodium dodecylsulfonate, dodecyl sulfate Sodium or sodium pentadecylcarboxylate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the aqueous surfactant solution described in Step 1 is dodecylbenzene with a molar concentration of 0.001mol / L to 0.005mol / L Sodium sulfonate, sodium dodecyl sulfate with molar concentration of 0.015mol / L to 0.045mol / L, sodium dodecyl sulfate with molar concentration of 0.012mol / L to 0.036mol / L or, molar concentration of 0.0012 mol / L~0.0056mol / L of sodium pentadecylcarboxylate. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com