Material feeder suitable for easily-bridged materials

A feeder and medium technology, which is applied in the field of taking and feeding materials, achieves the effects of small system changes, strong medium adaptability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The bridging medium is a fuel with a low viscosity and a high moisture content. The feeder is a screw feeder.

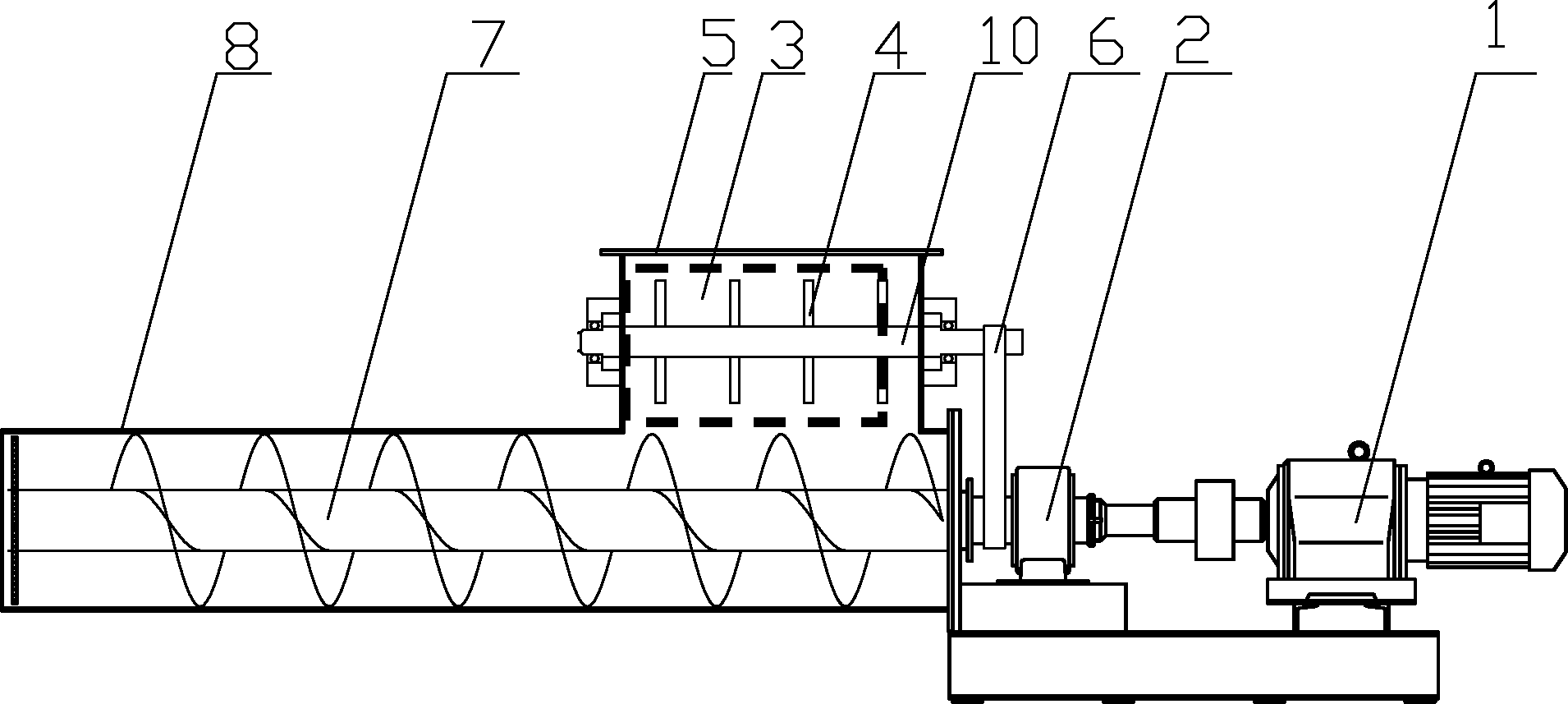

[0026] Such as figure 1 As shown, it is a material feeder suitable for bridging media, which includes a shell 8, which is connected to a silo 5, the upper part of the silo 5 has a feed inlet, and an agitator 3 is installed on the bottom of the silo wall, The stirrer 3 is composed of a stirring shaft 10 and a cutting device 4 on the stirring shaft 10. There is a spiral blade shaft 7 in the housing 8. The arrangement direction of the stirrer 3 is parallel to the axial direction of the spiral blade shaft 7, and the cutting device 4 is a protrusion Type, the screw drive device 1 is connected to the agitator 3 through the agitator transmission device 6. The agitator transmission device 6 is a transmission gear, and can also be a transmission mechanism such as a chain or a screw. The screw drive device 1 is electrically connected to the control cabinet, and the other e...

Embodiment 2

[0029] The bridging medium is a fuel with relatively high viscosity, and the feeder is a screw feeder.

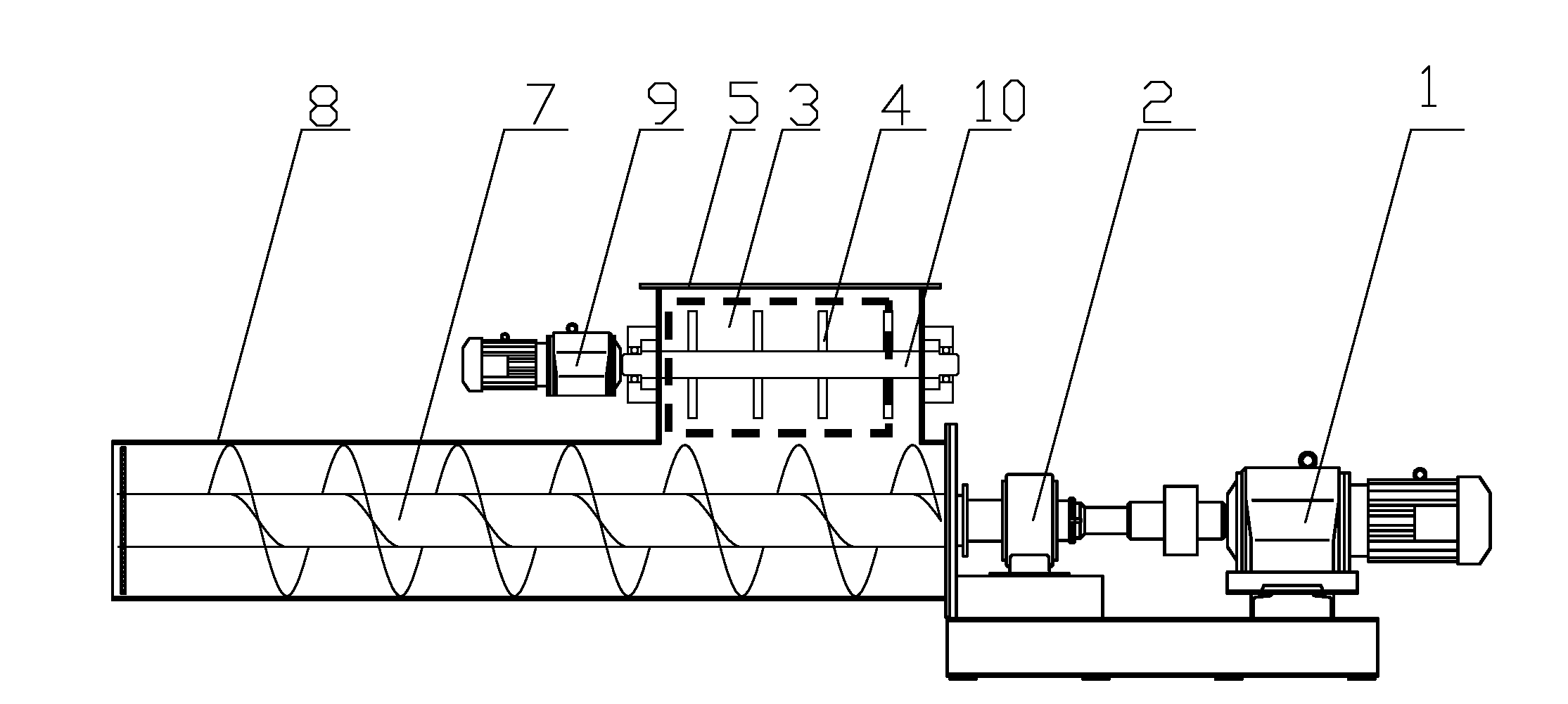

[0030] Such as figure 2 As shown, it is a material feeder suitable for bridging media, which includes a shell 8, which is connected to a silo 5, the upper part of the silo 5 has a feed inlet, and an agitator 3 is installed on the bottom of the silo wall, The agitator 3 is the cutting device 4, the housing 8 has a spiral blade shaft 7, the arrangement direction of the agitator 3 is parallel to the spiral blade shaft 7, the cutting device 4 is a shaftless spiral type, and the agitator 3 is connected to an independent agitator drive Device 9, the agitator drive device 9 is a motor, the screw drive device 1 is electrically connected to the control cabinet, the other end is connected to the bearing housing 2, the screw blade shaft 7 is installed on the bearing housing 2, the agitator drive device 9 and the screw drive device 1 are all motors.

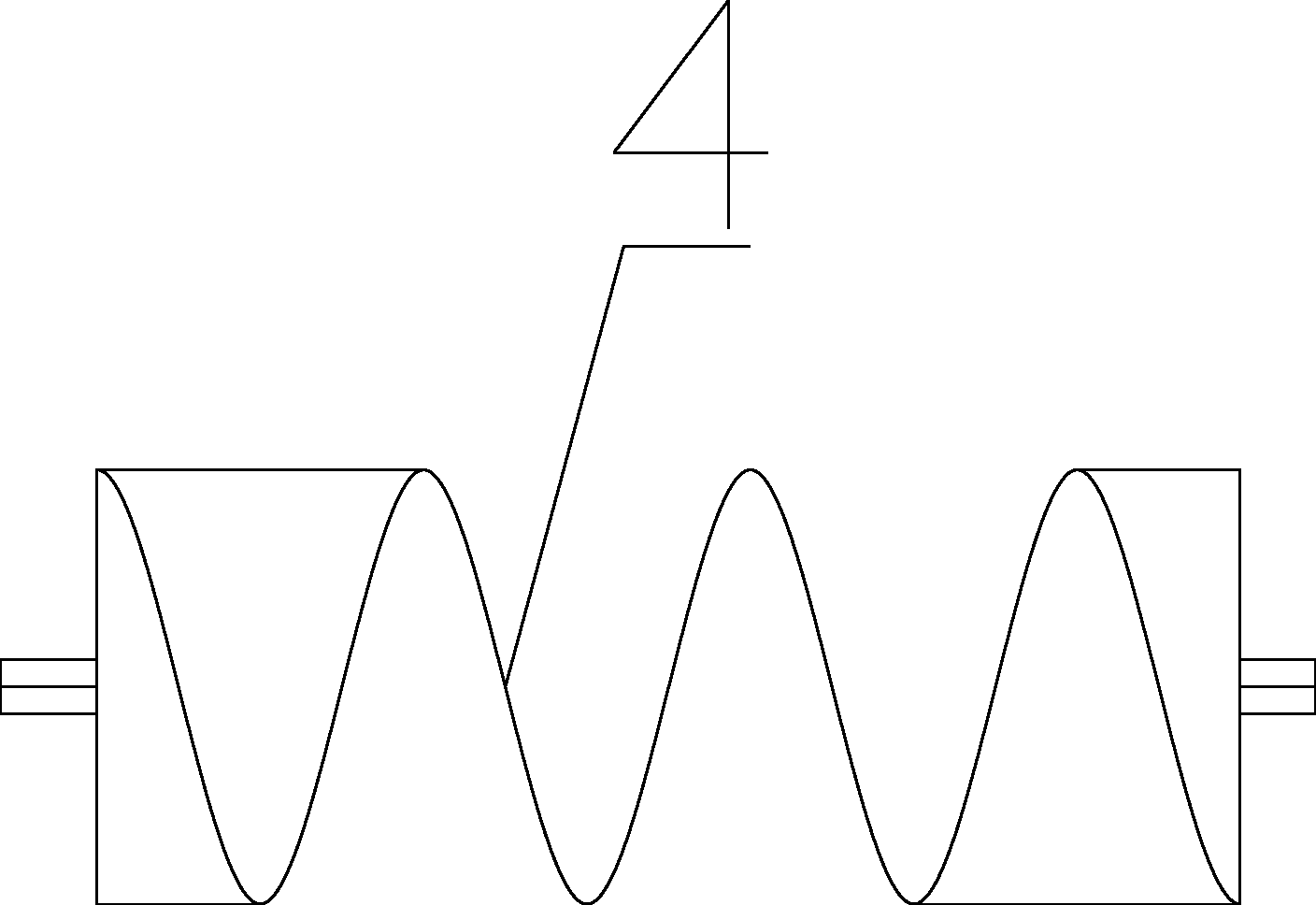

[0031] Such as image 3 Shown is a sc...

Embodiment 3

[0034] The easy bridging medium is a fuel with a low density, such as biomass fuel, and the feeder is a screw feeder.

[0035] The difference in structure from the first embodiment is that the cutting device 4 is a fin type or a rotary plough type.

[0036] Such as Figure 4 Shown is a schematic structural diagram of the fin-type cutting device 4, which has a large resistance (corresponding to a greater disturbance to the material). Because biomass fuels such as rice husks, bark, etc. have low density and are not easy to stick, Therefore, the cutting effect can be better achieved with this sheet type.

[0037] Such as Figure 5 As shown, it is a schematic diagram of the structure of the rotary tillage type cutting device 4, and its resistance is relatively large (corresponding to greater disturbance to the material), and it is also suitable for fuel with a relatively low density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com