Method for preparing machinable microcrystal glass material with high bioactivity

A bioactive, glass-ceramic technology, applied in the field of bioactive materials, can solve the problems of high raw material requirements, high price, and high sintering temperature, and achieve the effects of improving biological activity, shortening sintering time, and reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

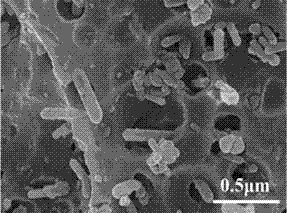

Image

Examples

Embodiment 1

[0029] (1) Preparation of hydroxyapatite powder: Dissolve 125mL ethanol in 375mL deionized water to prepare an ethanol solution with a mass fraction of 25%, dissolve 6.84g ammonium dihydrogen phosphate in the ethanol solution, add ammonia water to adjust the pH value 10-11, prepare an ethanol solution of ammonium dihydrogen phosphate with a molar concentration of 0.12mol / L; dissolve 16.27g of calcium nitrate in 20mL of deionized water to prepare a calcium nitrate solution with a molar concentration of 3.5mol / L; The ammonium hydrogen ethanol solution was stirred at a high speed at 270rpm, while calcium nitrate solution was added to it, and a pH regulator was added to adjust the pH value to 7; high-speed centrifugation at 4000rpm for 10min, the obtained lower layer precipitate was washed with ethanol and then freeze-dried at -10°C 30h to obtain powder; calcining the above powder at 700°C for 3h, cooling, grinding, and passing through a 200-mesh sieve to obtain hydroxyapatite powd...

Embodiment 2

[0035] (1) Preparation of hydroxyapatite powder: Dissolve 125mL ethanol in 375mL deionized water to prepare an ethanol solution with a mass fraction of 25%, dissolve 6.84g ammonium dihydrogen phosphate in the ethanol solution, add ammonia water to adjust the pH value 10-11, prepare an ethanol solution of ammonium dihydrogen phosphate with a molar concentration of 0.12mol / L; dissolve 16.27g of calcium nitrate in 20mL of deionized water to prepare a calcium nitrate solution with a molar concentration of 3.5mol / L; The ammonium hydrogen ethanol solution was stirred at a high speed at 400rpm, while calcium nitrate solution was added to it, and the pH value regulator was added to adjust the pH value to 7; it was centrifuged at a high speed of 5000rpm for 5min, and the obtained lower precipitate was washed with ethanol and then freeze-dried at -5°C 40h to obtain powder; calcining the above powder at 750°C for 2.5h, cooling, grinding, and passing through a 200-mesh sieve to obtain hydr...

Embodiment 3

[0041] (1) Preparation of hydroxyapatite powder: Dissolve 125mL ethanol in 375mL deionized water to prepare an ethanol solution with a mass fraction of 25%, dissolve 6.84g ammonium dihydrogen phosphate in the ethanol solution, add ammonia water to adjust the pH value 10-11, prepare an ethanol solution of ammonium dihydrogen phosphate with a molar concentration of 0.12mol / L; dissolve 16.27g of calcium nitrate in 20mL of deionized water to prepare a calcium nitrate solution with a molar concentration of 3.5mol / L; The ammonium hydrogen ethanol solution was stirred at a high speed at 350rpm, while calcium nitrate solution was added to it, and the pH value regulator was added to adjust the pH value to 7; it was centrifuged at a high speed of 4500rpm for 8min, and the obtained lower precipitate was washed with ethanol and then freeze-dried at -8°C 35h to obtain powder; calcining the above powder at 800°C for 2h, cooling, grinding, and passing through a 200-mesh sieve to obtain hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com