Environment-friendly firework material composition and preparation method thereof

A material composition and technology of environmentally friendly fireworks, applied in the field of environmentally friendly fireworks material composition and its preparation, can solve the problems of no profit generation, irreplaceable, low production capacity, etc., and achieve the goal of creating profits, keeping production capacity unchanged, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

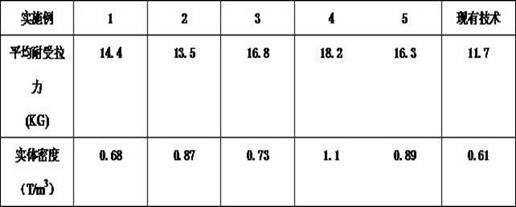

Examples

Embodiment 1

[0038] 1. According to the ratio of parts by weight, 15 parts of waste paper pulp (dry weight), 8 parts of polyvinyl alcohol powder, 2 parts of aluminum sulfate, 5 parts of Shuangfei powder, 70 parts of magnesium cement (40 parts of magnesium oxide, 30 parts of magnesium chloride), weighed Take each raw material component, stir each component evenly; add 160 components of 25°C water according to 100 parts of the above mixture, and stir evenly;

[0039] 2. Take 960 grams of the mixture prepared in the previous step and put it into the mold, vibrate on the vibration machine for 30 seconds to complete the mold filling, the frequency is 46HZ, cover the upper mold of the mold, leave it at room temperature for 50 minutes, open the mold and take out the product;

[0040] 3. Place the product in a ventilated place to dry naturally for 10 days.

Embodiment 2

[0042] 1. According to the ratio of parts by weight, 20 parts of sepiolite fiber, 11 parts of waste paper pulp (dry weight), 9 parts of bone glue, 3 parts of modified sodium silicate powder, 50 parts of ferric aluminate cement, and 0.2 parts of defoamer , 6.8 parts of gelatin slag powder, weigh each raw material component; according to 100 parts of the above mixture, first add bone glue to 135 parts of normal temperature water, let it stand for 30 minutes, then heat to 85 ° C and stir for 5 minutes, and then stir with other components Uniform;

[0043] 2. Take 1230 grams of the mixture prepared in the previous step and put it into the mold, vibrate on the vibration machine for 25 seconds to complete the mold filling, the frequency is 40HZ, cover the upper mold of the mold, leave it at room temperature for 25 minutes, open the mold and take out the product;

[0044] 3. Place the product in a ventilated place to dry naturally for 11 days.

Embodiment 3

[0046] 1. By weight, 5 parts of short animal hair waste, 11 parts of bamboo powder, 20 parts of acrylic rubber powder, 60 parts of sulphoaluminate cement, and 4 parts of Shuangfei powder, each raw material component is weighed, and each component Stir evenly; add 145 components of 60°C water according to 100 parts of the above mixture, and stir evenly;

[0047] 2. Take 1140 grams of the mixture prepared in the previous step and put it into the mold, vibrate on the vibration machine for 20 seconds to complete the mold filling, the frequency is 37HZ, cover the upper mold of the mold, leave it at room temperature for 45 minutes, open the mold and take out the product;

[0048] 3. Place the product in a ventilated place to dry naturally for 10 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com