Cleaning agent for clearing away resins and soldering

A cleaning agent and welding trace technology, which is applied in the direction of detergent composition, non-surface active cleaning solvent, non-surface active detergent composition, etc., can solve the problems of strong corrosion ability and low stability, and achieve less loss and better recovery Easy and safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

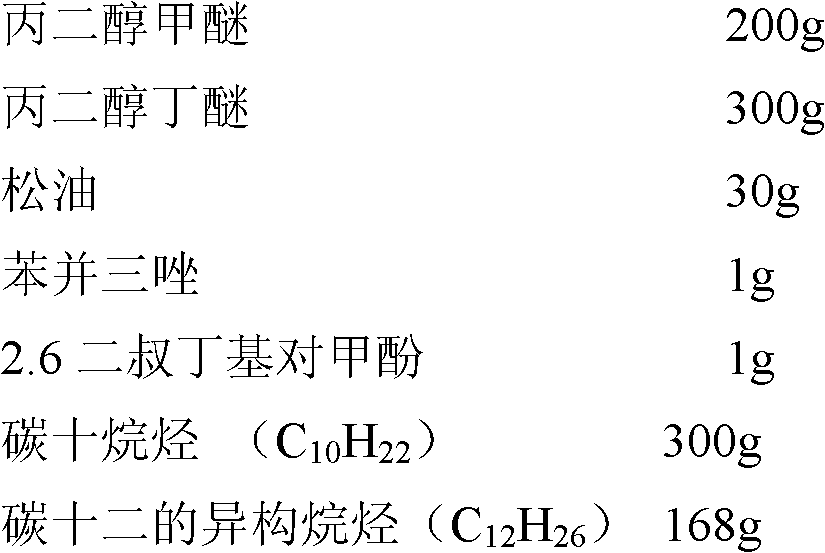

[0029] A cleaning agent for removing resin and welding marks, its composition and weight are as follows: (take 1000g product as an example)

[0030]

[0031] A kind of preparation method of the cleaning agent that is used to remove resin and welding mark is as follows:

[0032] (1) 1 gram of 2.6 di-tert-butyl-p-cresol is dissolved in a hydrocarbon solvent of 50-100 g with a beaker, and is added to the reaction kettle together with the remaining hydrocarbon solution;

[0033] (2) Use a beaker to dissolve 1 gram of benzotriazole in 50-100 g of alcohol ether solvent, and add it to the reaction kettle together with the remaining alcohol ether solution

[0034] (3) Add pine oil and stir evenly to obtain this product.

[0035] The quality standard of this environment-friendly resin and solder trace cleaning agent:

[0036] Appearance: colorless transparent liquid;

[0038] Specific gravity: 0.79-0.80g / ml;

[0039] Flash point (closed): ≥50°C;

...

Embodiment 2

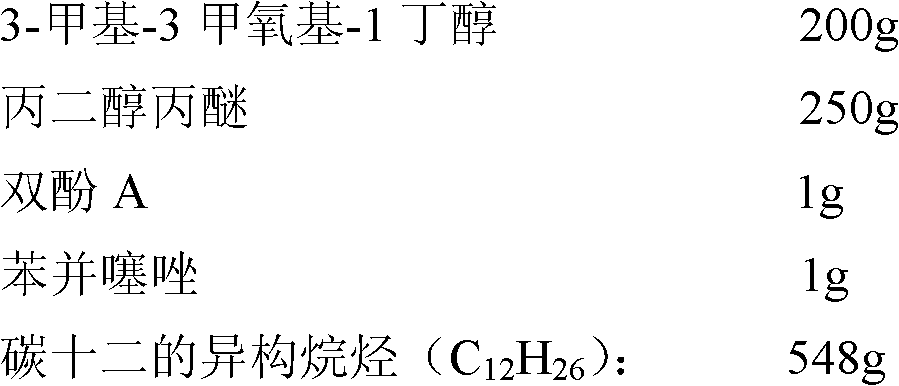

[0045] A cleaning agent for removing resin and welding marks, its composition and weight are as follows: (take 1000g product as an example)

[0046]

[0047] The steps of its preparation method are the same as in Example 1.

[0048] The cleaning agent quality standard for removing resin and solder traces:

[0049] Appearance: colorless transparent liquid

[0050] Odor: Slight solvent smell

[0051] Specific gravity: 0.79-0.80g / ml

[0052] Flash point (closed): ≥50°C

[0053] Boiling range: 150-174°C

[0054] Hazardous chemical grade: Class 3.3, high flash point, flammable liquid;

[0055] Acute oral toxicity (LD50mg / Kg): >15000;

[0056] Ozone destruction coefficient: 0.00;

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com