Weaving diaphragm cloth for electrolytic nickel and weaving method thereof

An electrolytic nickel and diaphragm cloth technology, applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of corrosion damage to the diaphragm, increase the cost of processes and use, and the electrolyte does not tend to be neutral, and achieve high electrolysis efficiency. The effect of wide application and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

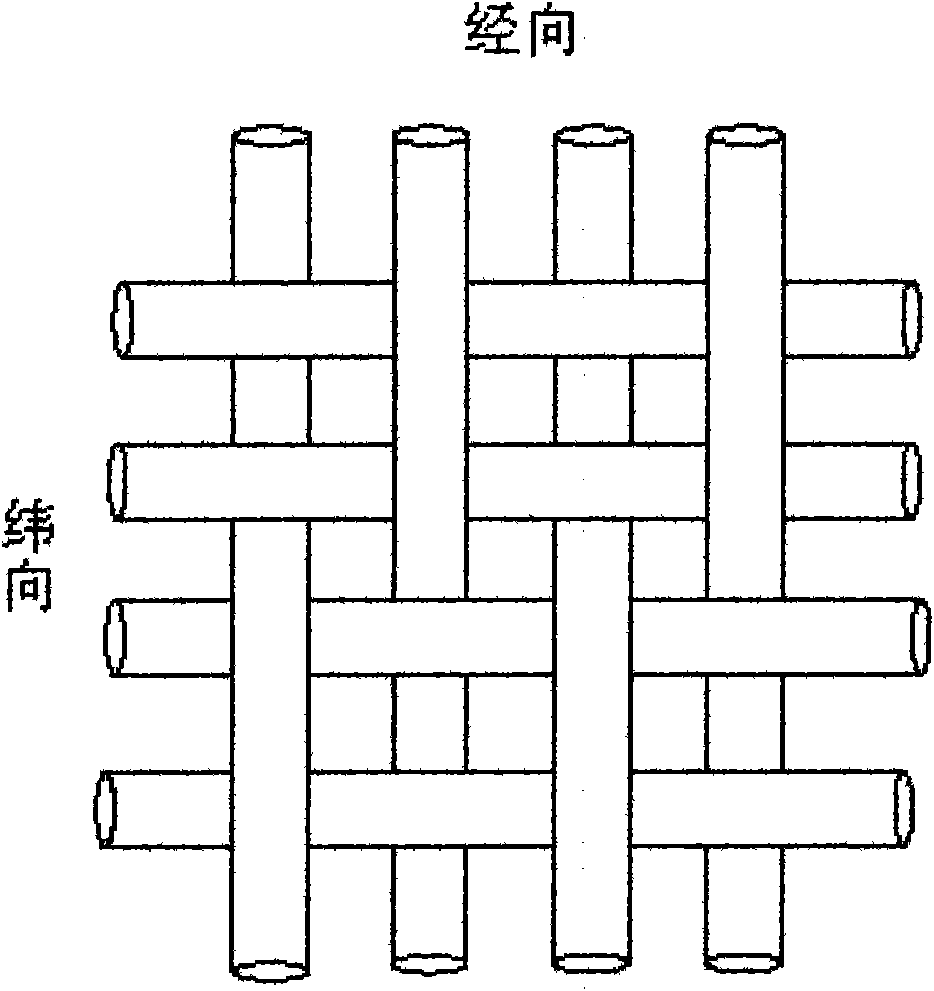

[0040] A woven diaphragm fabric for electrolytic nickel, which also meets the following requirements: the warp and weft yarns of the woven diaphragm fabric for electrolytic nickel simultaneously use polyester / cotton blended yarn, and the blending ratio is 65 / 35; The raw yarn count is warp yarn (21±1)S / 10, weft yarn is (21±1)S / 5; warp and weft density respectively: warp density 150±1 strand / 10cm, weft density 100±1 strand / 10cm .

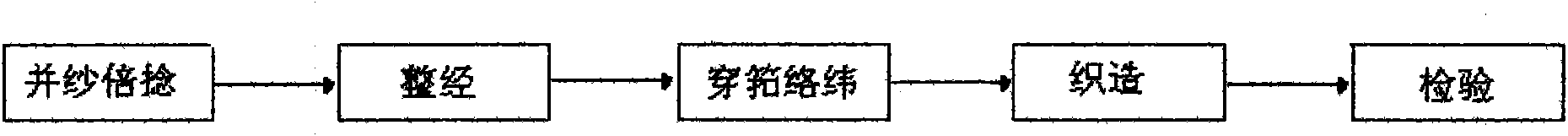

[0041] The weaving method of woven diaphragm cloth for electrolytic nickel as described above, the weaving method is carried out according to the following process steps: 1) Double-twisting: polyester-cotton yarn or polyester-cotton and special fiber ply and twisting; 2) warping: according to The process requires that a certain amount of two-for-one twisted yarn is evenly wound on the weaving shaft; 3) Fabric weave: In order to ensure the improvement of product performance, we adopt a warp and flattening weave; 4) Weaving: On the loom, warp and weft yar...

Embodiment 2

[0044] The content of this embodiment is basically the same as that of embodiment 1, and the difference lies in:

[0045] The woven diaphragm fabric for electrolytic nickel also meets the following requirements: the warp and weft yarns of the woven diaphragm fabric for electrolytic nickel simultaneously use polyester / cotton blended yarn, and the blending ratio is 100 / 0 (that is, pure polyester spinning) The raw material yarn count is warp yarn (17±1)S / 10, weft yarn is (25±1)S / 5; warp and weft density are respectively: warp density 164±1 strand / 10cm, weft density is 114±1 strand / 10cm.

[0046] The woven diaphragm fabric used for electrolytic nickel forms a fabric when the water pressure is 150mm, the water permeability standard is 80±20L / m 2 ·H below; the resistance of the fabric is less than 20±5OM·cm 2 .

Embodiment 3

[0048] The content of this embodiment is basically the same as that of embodiment 1, and the difference lies in:

[0049] The woven diaphragm fabric for electrolytic nickel also meets the following requirements: the warp and weft yarns of the woven diaphragm fabric for electrolytic nickel simultaneously use polyester / cotton blended yarn, and the blending ratio is 0 / 100 (that is, pure cotton spinning) The raw yarn count is warp yarn (25±1)S / 10, weft yarn is (17±1)S / 5; warp and weft density are respectively: warp density of 150±15 pieces / 10cm, and weft density of 100±15 pieces / 10cm.

[0050] The woven diaphragm fabric used for electrolytic nickel forms a fabric when the water pressure is 150mm, the water permeability standard is 25±15L / m 2 ·H below; the resistance of the fabric is less than 15±10OM·cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com