Fischer-Tropsch synthesis catalyst by taking modified alumina as carrier and application thereof

A Fischer-Tropsch synthesis and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of easy generation of fine powder, collision friction, and impact on wax products Issues such as quality improvement and upgrading to achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

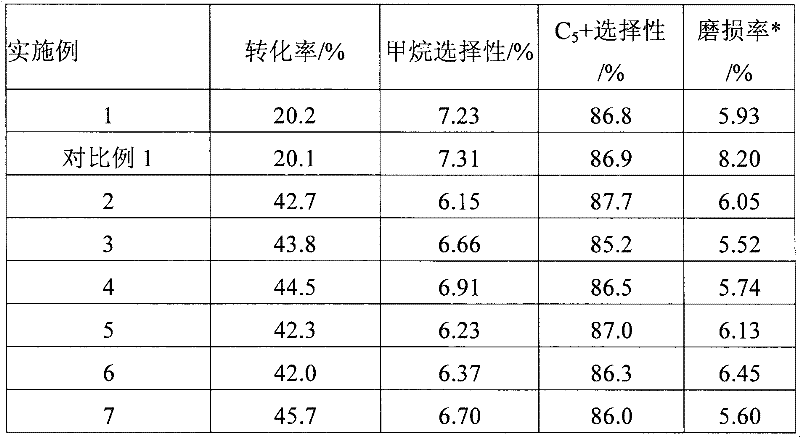

Examples

Embodiment 1

[0038] (1) Modified alumina and its preparation

[0039] Add 75 ml of concentrated ammonia water (analytical pure product, mass fraction 25%) into 75 ml of deionized water, and add 23.44 g of zinc nitrate hexahydrate to dissolve to obtain an alkaline Zn solution, the pH of the solution is about 12.0. 100 grams of γ-alumina (Sasol product, average particle size 55 microns) was added to the above solution, and the solution was left under stirring for 6 hours. After filtering, the filter cake was placed in an oven at 140°C for 6 hours and then calcined in a muffle furnace at 800°C for 4 hours.

[0040] (2) Catalyst and its preparation

[0041] 139 g of cobalt nitrate hexahydrate was dissolved in 50 mL of deionized water to obtain an immersion liquid. After dispersing the carrier obtained in step (1) into the impregnation solution and stirring at room temperature for 1 hour, a dried catalyst sample was obtained by rotary evaporation. After the sample was dried at 120°C for 2 hours, it ...

Embodiment 2

[0053] (1) Modified alumina and its preparation

[0054] Add 75 ml of concentrated ammonia water (analytical pure product, mass fraction 25%) into 75 ml of deionized water, and add 23.44 g of zinc nitrate hexahydrate to dissolve to obtain an alkaline Zn solution, the pH of the solution is about 12.0. 100 grams of γ-alumina (Sasol product, average particle size 55 microns) was added to the above solution, and the solution was left under stirring for 6 hours. After filtering, the filter cake was placed in an oven at 140°C for 6 hours and then calcined in a muffle furnace at 800°C for 4 hours.

[0055] (2) Catalyst preparation

[0056] 139 g of cobalt nitrate hexahydrate and 4.50 g of lanthanum nitrate hexahydrate were dissolved in 50 mL of deionized water, and 9.48 g of a Ru 1.5% nitrosyl ruthenium nitrate solution was added to obtain an impregnating solution. After dispersing the carrier obtained in step (1) into the impregnation solution and stirring at room temperature for 1 hour,...

Embodiment 3

[0060] (1) Modified alumina and its preparation

[0061] Add 75 mL of concentrated ammonia (analytical pure product, mass fraction 25%) into 75 mL of deionized water, and add 22.93 g of cobalt nitrate hexahydrate to dissolve to obtain an alkaline Co solution, the pH of the solution is about 12.0. 100g of γ-alumina (Sasol product, average particle size 55 microns) was added to the above solution and the reaction was continuously stirred for 6 hours. After filtering, the filter cake was placed in an oven at 140°C for 6 hours and then calcined in a muffle furnace at 800°C for 4 hours.

[0062] (2) Catalyst preparation

[0063] 139 g of cobalt nitrate hexahydrate and 4.45 g of cerous nitrate hexahydrate were dissolved in 50 mL of deionized water, and 9.48 g of nitrosyl ruthenium nitrate solution containing 1.5% Ru was added to obtain an impregnating solution. Disperse the calcined carrier into the impregnation solution and stir at room temperature for 1 hour, and then rotate it to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com