Method of preparing battery-grade lithium dihydrogen phosphate by recrystallized lithium hydroxide

A technology of lithium dihydrogen phosphate and lithium hydroxide, which is applied in the direction of phosphorus compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of impurity enrichment, long process, and cumbersome impurity removal, so as to improve recovery rate and reduce energy consumption. Consumption and cost, the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

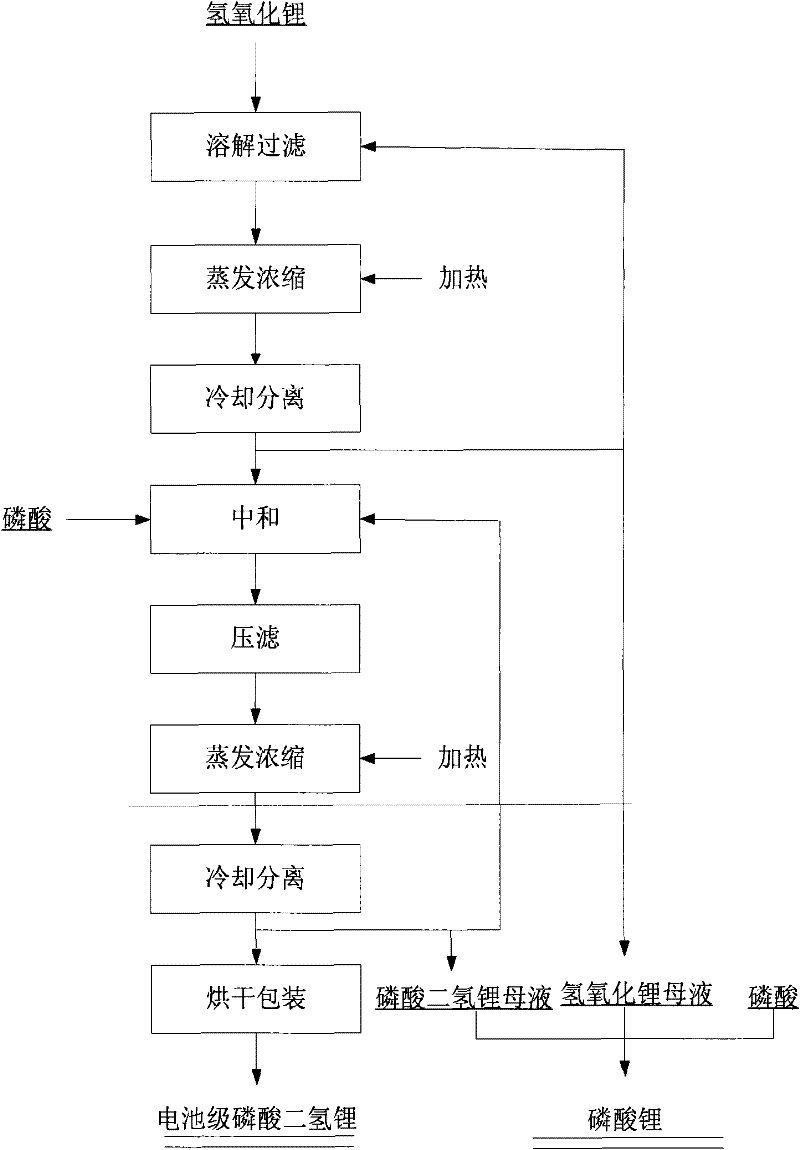

[0014] see figure 2 , the method for preparing battery-grade lithium dihydrogen phosphate in the present embodiment 1 includes the following steps:

[0015] (1) 800kg of industrial lithium hydroxide was added to 4000L of pure water, fully stirred, and after the lithium hydroxide was completely dissolved, filtered to remove insoluble impurities to obtain a pure lithium hydroxide solution;

[0016] (2) Evaporate the obtained clean liquid, and control the evaporation vapor pressure at 0.1-0.3Mp to prevent the lithium hydroxide solution from overflowing at an excessively fast evaporation rate. After the clean liquid is evaporated and concentrated to 1000L, it is cooled, and the cooling temperature is controlled at 20-30 Degree Celsius, after cooling is completed, separate with a centrifuge, obtain 640kg of recrystallized lithium hydroxide and a lithium hydroxide mother liquor after the separation, and the lithium hydroxide mother liquor returns to the dissolving filtration proces...

Embodiment 2

[0022] see figure 2 , the method for preparing battery-grade lithium dihydrogen phosphate in this embodiment 2 includes the following steps:

[0023] (1) 800kg of industrial lithium hydroxide was added to 4000L of pure water, fully stirred, and after the lithium hydroxide was completely dissolved, filtered to remove insoluble impurities to obtain a pure lithium hydroxide solution;

[0024] (2) Evaporate the obtained clean liquid, and control the evaporation vapor pressure at 0.1-0.3Mp to prevent the lithium hydroxide solution from overflowing at an excessively fast evaporation rate. After the clean liquid is evaporated and concentrated to 1000L, it is cooled, and the cooling temperature is controlled at 20-30 Degree Celsius, after cooling is completed, separate with a centrifuge, obtain 640kg of recrystallized lithium hydroxide and a lithium hydroxide mother liquor after the separation, and the lithium hydroxide mother liquor returns to the dissolving filtration process;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com