Method for preparing crystalline transitional metal boride - cobalt boride

A technology of transition metals and borides, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., to achieve the effects of simple process, abundant sources, and novel synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Weigh 0.465 g Co(OH) 2 and 0.540 g KBH 4 , after mixing uniformly in a mortar, press into tablets under a pressure of 20 MPa;

[0022] 2. Keep the pressed sheet at 600°C for 12 h under the protection of argon, and then slowly cool it down to room temperature. The obtained product was fully washed with deionized water and ethanol, and vacuum-dried at 80°C for 12 h to obtain the product crystalline CoB.

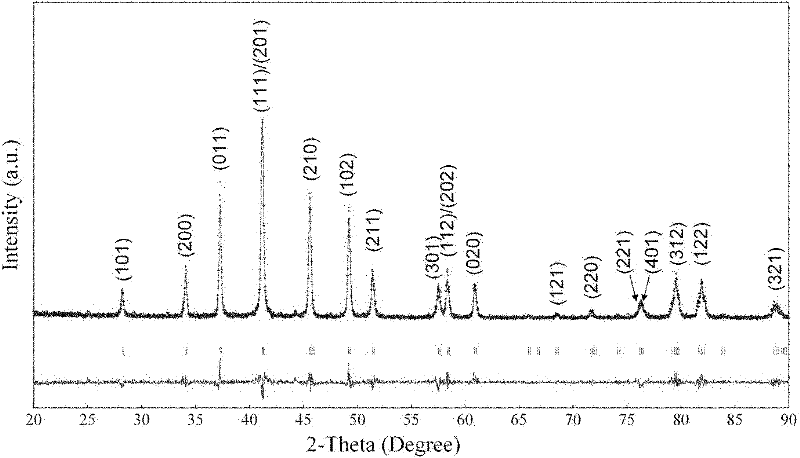

[0023] figure 1 is the XRD pattern of the obtained material. Compared with the standard card, it can be seen that the synthesized material is an orthorhombic crystal system.

Embodiment 2

[0025] 1. Weigh 0.512 g Co 3 o 4 and 0.540 g KBH 4 , after mixing uniformly in a mortar, press into tablets under a pressure of 20 MPa;

[0026] 2. Keep the pressed sheet at 600°C for 12 h under the protection of argon, and then slowly cool it down to room temperature. The obtained product was fully washed with deionized water and ethanol, and vacuum-dried at 80°C for 12 h to obtain the product crystalline CoB.

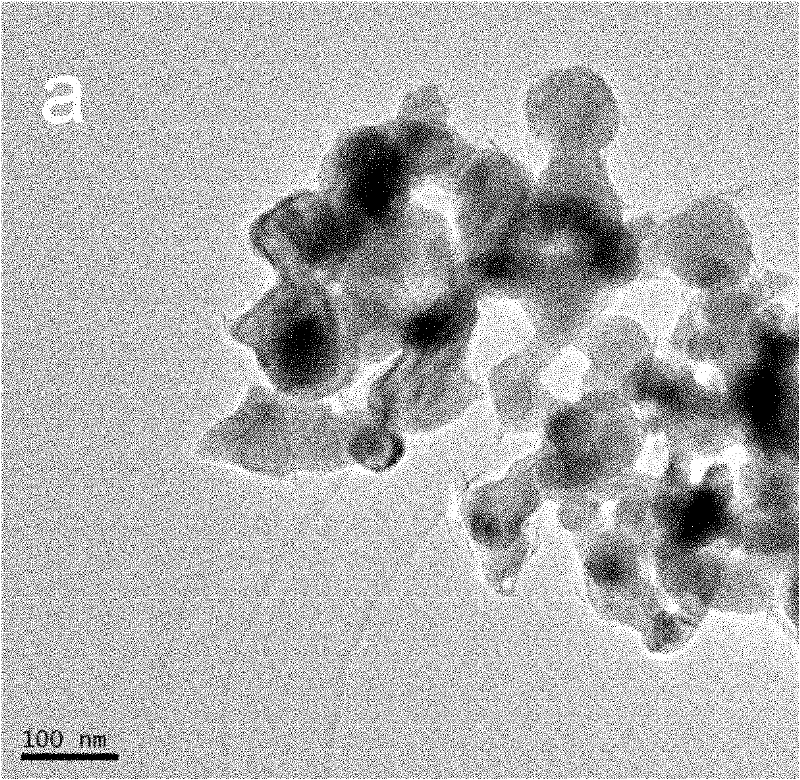

[0027] figure 2 is the TEM image of the as-prepared crystalline CoB. It can be seen from the figure that the crystalline CoB is composed of nanospheres with a diameter of tens to hundreds of nm.

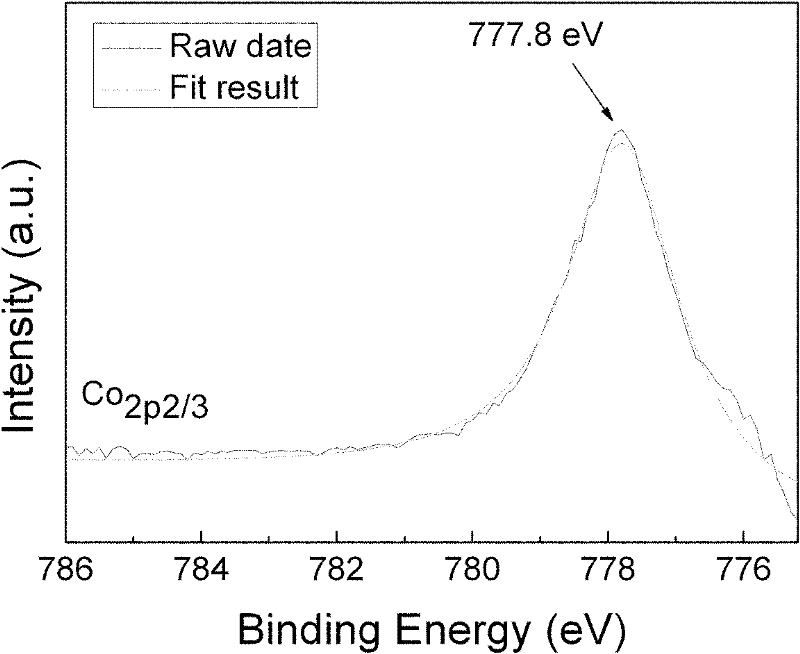

[0028] image 3 and Figure 4 It is the XPS pattern of the as-prepared crystalline CoB. It can be seen from the figure that Co and B exist in the form of CoB, indicating that the obtained CoB is of high purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com