Method for treating wastewater of rubber antioxidant (RD) production device

A technology of rubber antioxidant and production device, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problems of no preparation of coal-water slurry additives, waste water discharge polluting the environment, etc. , to achieve the effect of solving emission and governance problems, reducing pollution and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

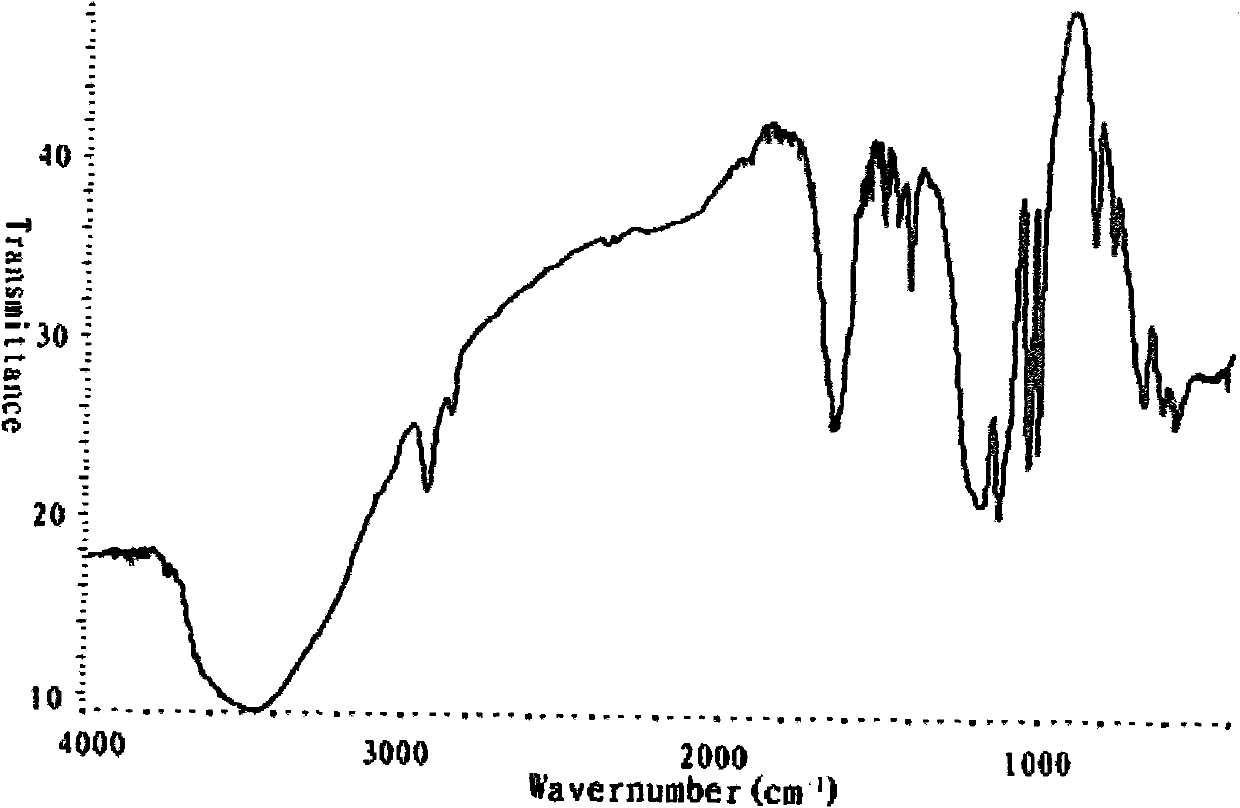

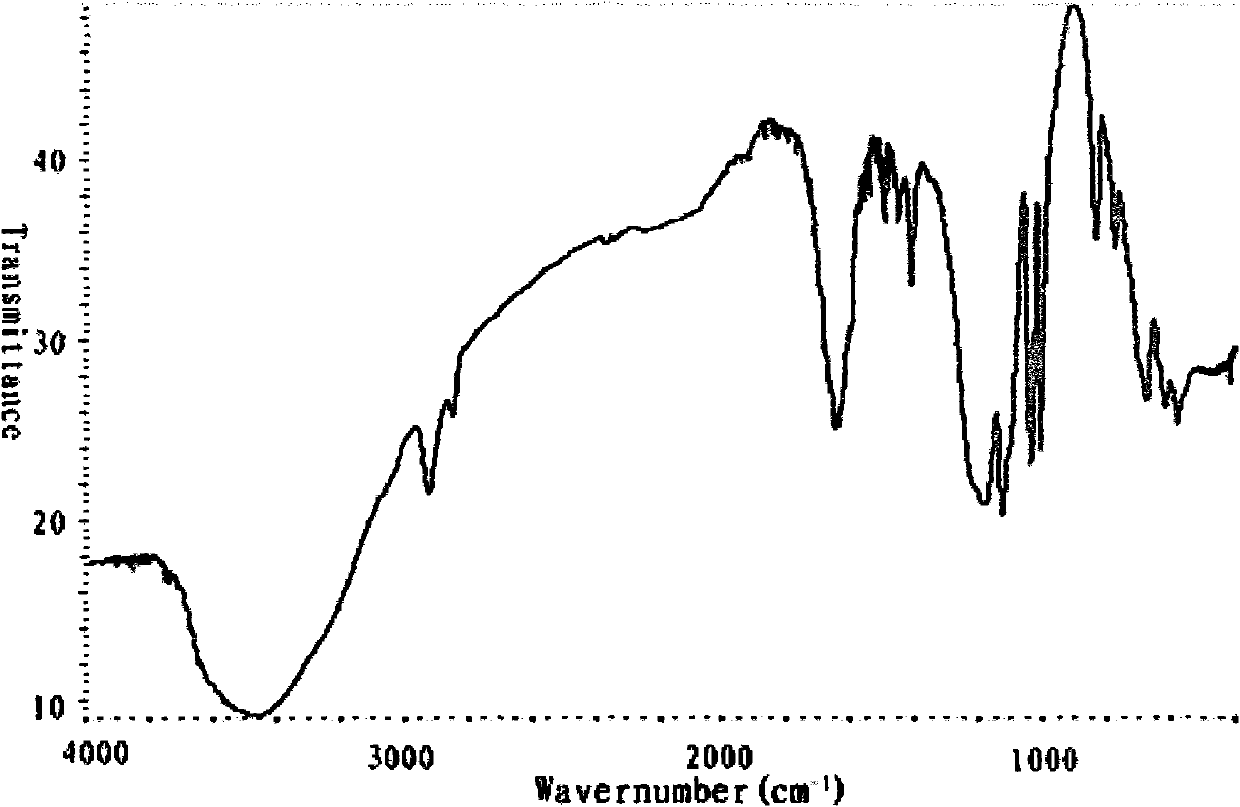

Image

Examples

Embodiment 1

[0032] Step 1: Weigh 2 g of polystyrene, add it to 40 g of sulfonating agent concentrated sulfuric acid, and then add 0.1 g of silver sulfate;

[0033] Step 2: heat up to 90°C, and react for 4 hours under stirring conditions to obtain the reaction product polystyrenesulfonic acid;

[0034] Step 3: Add the above reaction product to 160g of waste water from the production plant of rubber antioxidant RD (pH=13, COD=16000mg / L), adjust the pH to 7 with sodium hydroxide, and prepare the polystyrene sulfonate additive for coal-water slurry Sodium acid solution.

[0035] The non-sticky coal is ground by a ball mill to obtain coal powder with an average particle size of less than 75 μm and the mass percentage of particles is greater than 80%. After the obtained coal-water slurry additive and non-sticky coal powder are prepared and mixed according to the mass ratio of 38:62, Stir with an electric mixer for 10 minutes to obtain a coal-water slurry. When the additive amount of this coal...

Embodiment 2

[0037] Step 1: Weigh 4g of polystyrene, add it to 50g of sulfonating agent concentrated sulfuric acid, and then add 0.3g of silver sulfate;

[0038] Step 2: heat up to 95°C, and react for 5 hours under stirring conditions to obtain the reaction product polystyrenesulfonic acid;

[0039] Step 3: Add the above reaction product to 300g of waste water from the production plant of rubber antioxidant RD (pH=12, COD=21000mg / L), adjust the pH to 7 with sodium hydroxide, and obtain polystyrene sulfonate, an additive for coal-water slurry Sodium acid solution.

[0040] The non-sticky coal is ground by a ball mill to obtain coal powder with an average particle size of less than 75 μm and the mass percentage of particles is greater than 80%. After the obtained coal-water slurry additive and non-sticky coal powder are prepared and mixed according to the mass ratio of 38:62, Stir with an electric mixer for 10 minutes to obtain a coal-water slurry. When the additive amount of the coal-wate...

Embodiment 3

[0042] Step 1: Weigh 6g of polystyrene, add it to 100g of sulfonating agent concentrated sulfuric acid, and then add 0.6g of silver sulfate;

[0043] Step 2: heat up to 98°C, and react for 3 hours under stirring conditions to obtain the reaction product polystyrenesulfonic acid;

[0044] Step 3: Add the above reaction product to 500g of waste water from the production plant of rubber antioxidant RD (pH=11, COD=6000mg / L), adjust the pH to 7 with sodium hydroxide, and obtain polystyrene sulfonate, an additive for coal-water slurry Sodium acid solution.

[0045]The non-sticky coal is ground by a ball mill to obtain coal powder with an average particle size of less than 75 μm and the mass percentage of particles is greater than 80%. After the obtained coal-water slurry additive and non-sticky coal powder are prepared and mixed according to the mass ratio of 38:62, Stir with an electric mixer for 10 minutes to obtain a coal-water slurry. When the additive amount of the coal-water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com