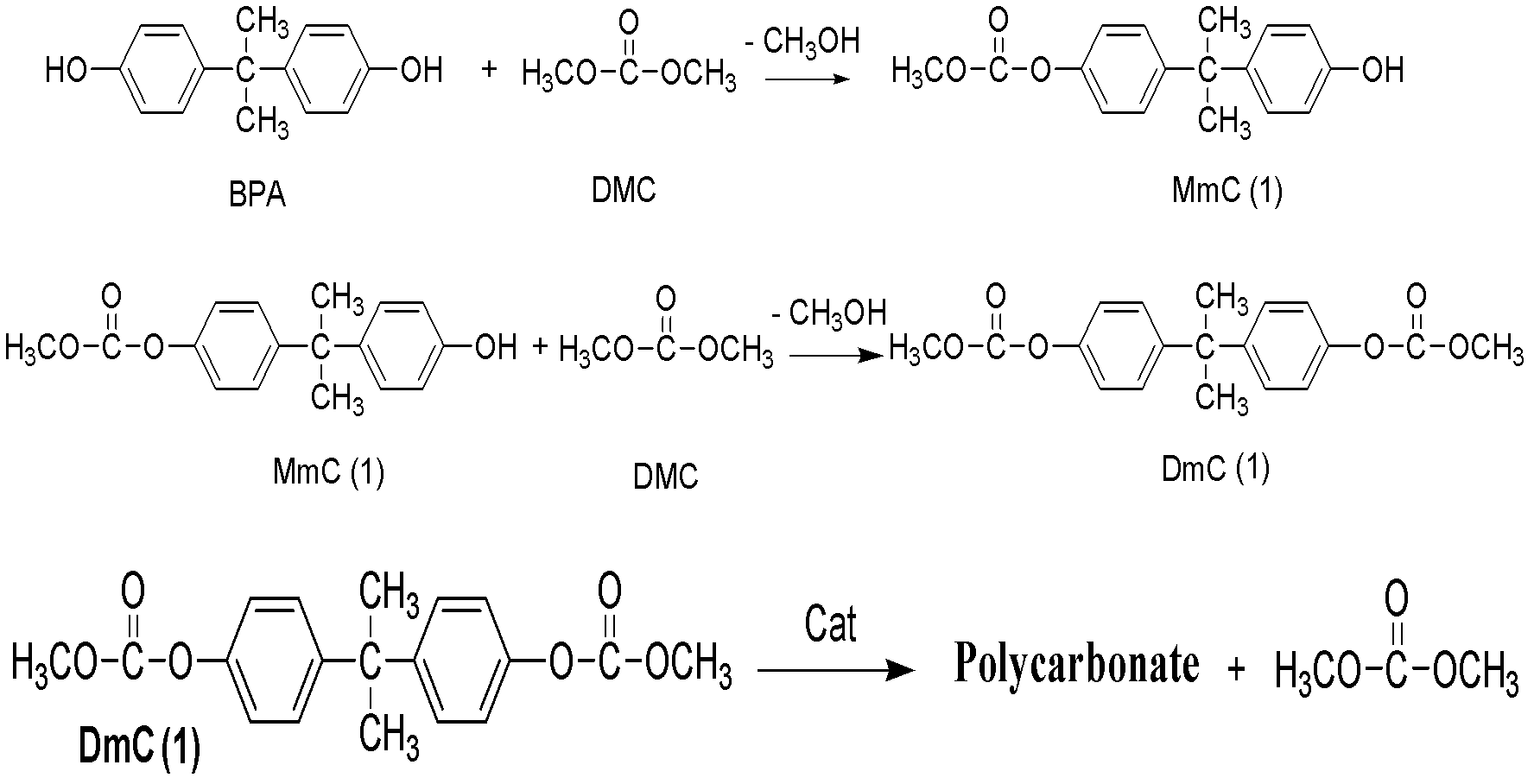

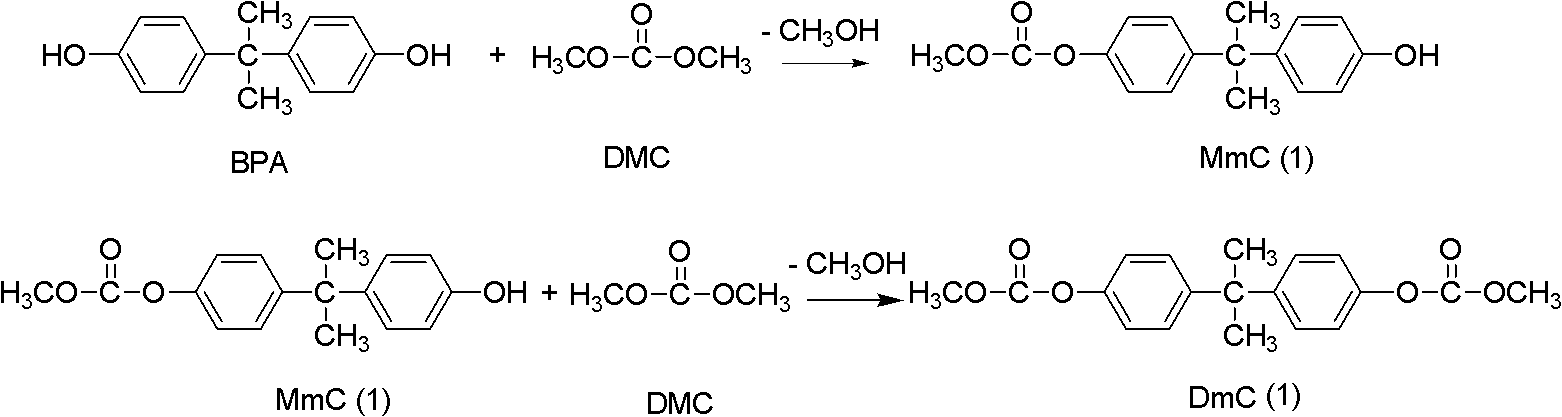

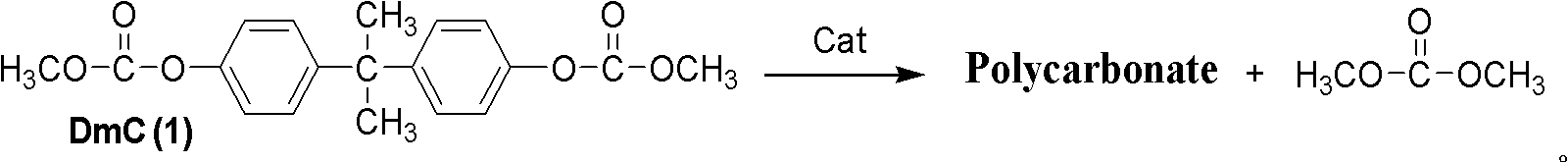

Preparation method of intermediate dimethoxy carbonic acid bisphenol A diester

A technology of dimethoxycarbonic acid bisphenol and intermediates, which is applied in the field of preparation of fine chemical intermediates, can solve the problems of low DmC selectivity and yield, unfavorable large-scale production, increase of polycondensation temperature and the like, and achieves short reaction time. , less by-products, good overall performance of polyester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Feeding: DMC / BPA / (Ar) 2SnO=4mol / 1mol / 1.2g, react in an autoclave, replace the air in the autoclave with nitrogen, react at 220°C for 12 hours, and stir at a speed of 150R / Min. After the reaction is completed, the catalyst is filtered, and the excess DMC and by-product methanol are distilled off to obtain a white powder with a yield higher than 92%. Gained white powder is dissolved in the mixed liquid of methanol and water at 65 DEG C, the volume ratio of alcohol and water is controlled at 1: 1, and the colorless massive solid that cools out is the intermediate DmC (1) that the present invention seeks, The product purity is higher than 99.8%, and the yield is higher than 90%.

Embodiment 2

[0026] Feeding: DMC / BPA / (Ph) 2 SnO=8mol / 1mol / 8g, react in an autoclave, replace the air in the autoclave with nitrogen, react at 220°C for 6 hours, and stir at a speed of 100R / Min. The crude product recovery process is the same as in Example 1, and the yield is higher than 96%; the obtained white powder is dissolved in a mixture of methanol and water at 70°C, and the volume ratio of alcohol to water is controlled between 1:2, and a colorless block is precipitated after cooling The solid is DmC (1), the product purity is higher than 99.8%, and the yield is higher than 93%.

Embodiment 3

[0028] Feeding: DMC / BPA / (Ph) 2 SnO=12mol / 1mol / 6g, using atmospheric pressure kettle reaction, adopting the method of adding DMC dropwise to the BPA melt, the by-product methanol will be distilled after the reaction, and the reaction temperature is controlled at 200°C, the reaction is 8 hours, and the stirring speed is 150R / Min. The crude product recovery and recrystallization process are the same as in Example 1, the crude product yield is higher than 85%, the product purity is higher than 99.8%, and the recrystallization product yield is higher than 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com