Method for extracting natural activated products from orange drops

A technology of citrus and fruit drop, applied in chemical instruments and methods, preparation of organic compounds, sugar derivatives, etc., can solve the problems of insufficient utilization and waste of other components, and achieve the effect of improving the value of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

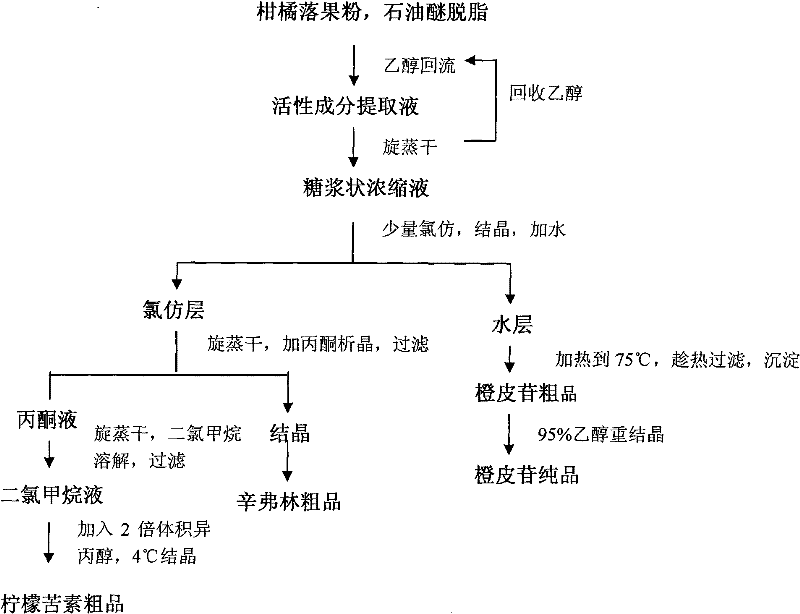

Method used

Image

Examples

Embodiment 1

[0032] 1. Experimental materials: The first batch of crushed navel oranges (the variety is Pengna, a high-quality navel orange variety widely promoted in southern China, and the fallen fruit of Pengna navel oranges came from the citrus garden of Wangchunhua Juice Co., Ltd., Songzi City, Hubei Province) was dried at 80°C. Physiological shedding and fruit of the second physiological shedding.

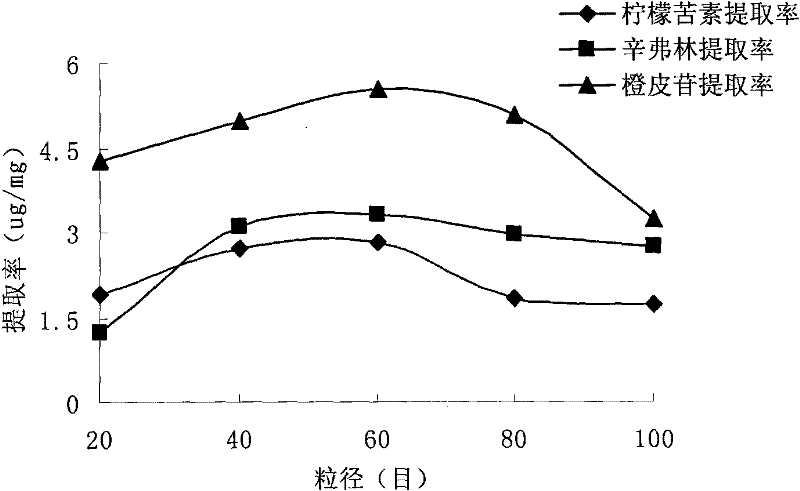

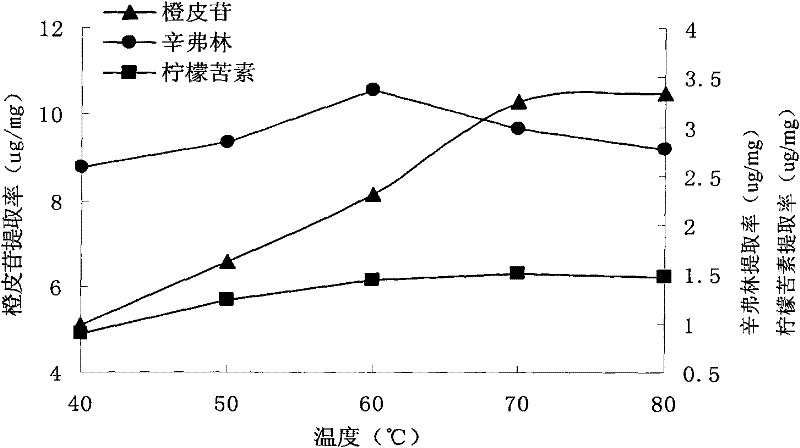

[0033] 2. Experimental method

[0034] (1) Clean the fallen navel oranges, dry them at 80° C., and then pulverize them through a 50-mesh analytical sieve to obtain pretreated citrus fallen fruits powder;

[0035] (2) Take by weighing 3.0g pretreated orange fruit drop powder, place in the Soxhlet extractor, connect the evaporating flask of constant weight, add sherwood oil, the weight / volume ratio of pretreatment orange fruit drop powder and petroleum ether is 1: 40. Heat and reflux in a water bath at 40-50°C for 8 hours, evaporate the petroleum ether and then dry at 100-105°C to obtain def...

Embodiment 2

[0041] Follow the basic steps of Example 1. Navel orange source is with embodiment 1.

[0042] (1) Clean the fallen navel oranges, dry them at 80° C., and then pulverize them through a 20-mesh analytical sieve to obtain pretreated citrus fallen fruits powder;

[0043] (2) Take by weighing 3.0g pretreated orange fruit drop powder, place in the Soxhlet extractor, connect the evaporating flask of constant weight, add sherwood oil, the weight / volume ratio of pretreatment orange fruit drop powder and petroleum ether is 1: 40. Heat and reflux in a water bath at 40-50°C for 8 hours, evaporate the petroleum ether and then dry at 100-105°C to obtain defatted citrus fruit drop powder;

[0044] (3) The defatted citrus fruit drop powder obtained in step (2) and ethanol are 1: 10 by weight / volume ratio, and the ethanol concentration is 90%, reflux extraction at 40 DEG C for 1-3h, filter, and the filtrate is for subsequent use; the filter residue is reused Repeat the extraction twice by t...

Embodiment 3

[0049] Follow the basic steps of Example 1. Navel orange source is with embodiment 1.

[0050] (1) Clean the fallen citrus fruits, dry them at 80° C., and then pulverize them through a 100-mesh analytical sieve to obtain pretreated citrus fallen fruits powder;

[0051] (2) Take by weighing 2.0-3.0g pretreated citrus fruit drop powder, place in the Soxhlet extractor, connect the evaporation flask with constant weight, add sherwood oil, the weight / volume ratio of pretreatment citrus fruit drop powder and sherwood oil is 1:40, heat and reflux in a water bath at 50°C for 8 hours, evaporate the petroleum ether and then dry at 100-105°C to obtain defatted citrus fruit drop powder;

[0052] (3) The weight / volume ratio of the degreased citrus fruit drop powder obtained in step (2) and ethanol is 1:50, the ethanol concentration is 50%, reflux extraction at 80°C for 1-3h, filter, and the filtrate is for subsequent use; the filter residue is reused Repeat the extraction twice by the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com