Porous ceramic ball and method for prolonging operation period of hydrogenation device

A hydrogenation device and ceramic ball technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, hydrocarbon oil treatment, etc., can solve the problem of shortening the operation period of the hydrogenation device and the pressure difference of the catalyst bed Improve the oxidation stability of paraffin waxes, improve the reaction performance, and improve the cetane number of diesel oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

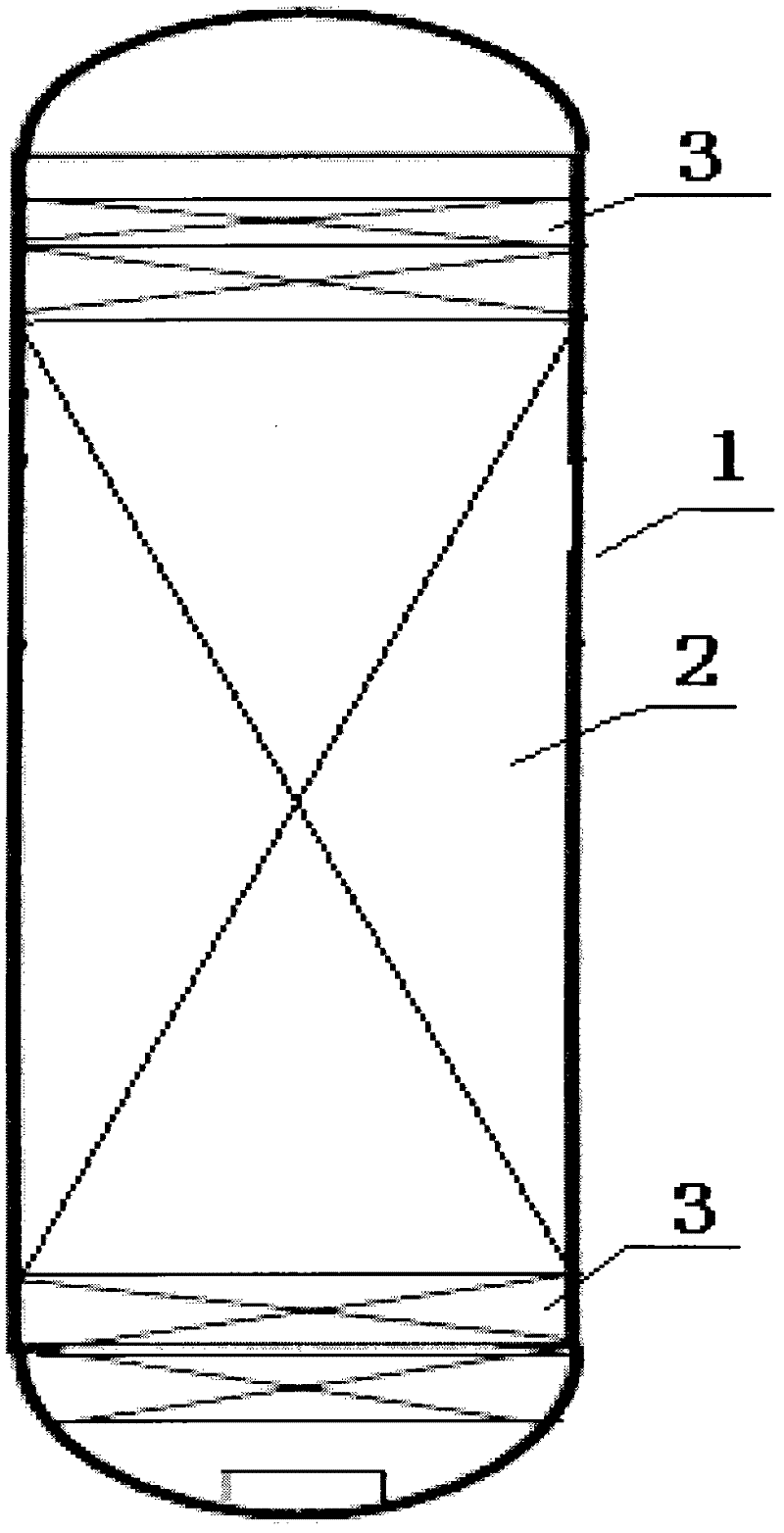

[0030] The lower part of the hydrogenation catalyst bed is filled with Φ5, Φ10 and Φ13 ceramic foam balls from top to bottom, and the upper part of the hydrogenation catalyst bed is filled with Φ13, Φ10 and Φ5 ceramic foam balls from top to bottom. The Φ5 ceramic foam ball on the upper part of the layer contains 1% molybdenum oxide. The filling thickness of each foam ceramic ball is 80mm. The reaction results are shown in Table 2.

Embodiment 2

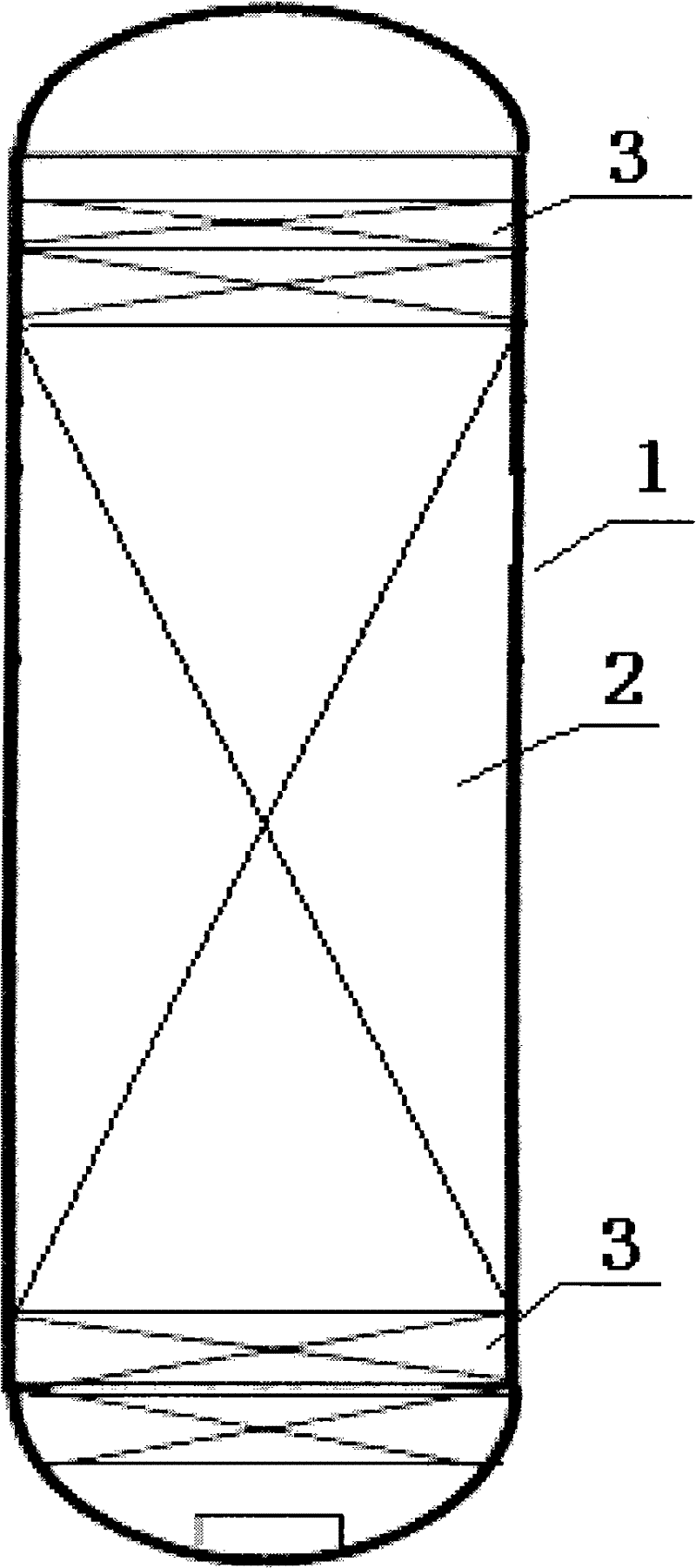

[0032] Φ15, Φ10, Φ6, and Φ3 honeycomb ceramic balls are loaded sequentially from top to bottom on the top of the hydrogenation catalyst bed, Φ10 honeycomb ceramic balls contain 0.5% molybdenum oxide, Φ6 honeycomb ceramic balls contain 1% molybdenum oxide and 0.5% nickel oxide, Φ3 honeycomb ceramic balls contain 2.5% molybdenum oxide and 0.5% nickel oxide, and the filling thickness of each honeycomb ceramic ball is 70mm. The lower part of the hydrogenation catalyst bed is inert ceramic balls packed conventionally. The reaction results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com