Method for manufacturing solar battery photoanode and product thereof

A solar cell, photoanode technology, applied in nanotechnology for material and surface science, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of high manufacturing cost, harsh process conditions, complex process equipment, etc. Achieve the effect of rapid synthesis, simple equipment and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

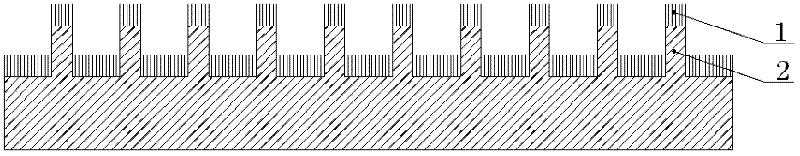

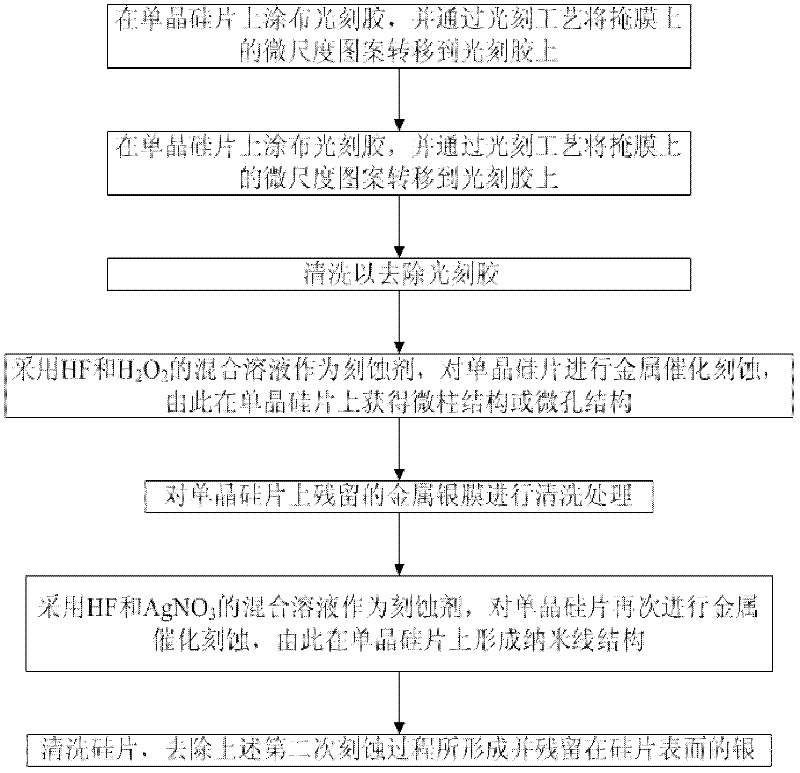

[0030] see figure 1 and image 3 , figure 1 It is a schematic diagram of the product structure prepared according to Embodiment 1 of the present invention, image 3 is a process flow block diagram of the manufacturing method according to the present invention. Such as image 3 and figure 1 Shown in, the method for manufacturing solar cell photoanode in the present embodiment comprises the following specific steps:

[0031] (a) Spin-coat AZ5214 photoresist on the monocrystalline silicon wafer as the photoanode substrate of the solar cell after surface cleaning treatment, and make the micro-scale pattern on the mask, that is, the structure in the order of microns, by photolithography The pattern is transferred to the photoresist, thereby forming the photoresist pattern of the microcolumn array; the microcolumn array here is a micron-scale columnar array structure;

[0032] (b) On the monocrystalline silicon wafer formed with the above-mentioned microcolumn array, adopt a s...

Embodiment 2

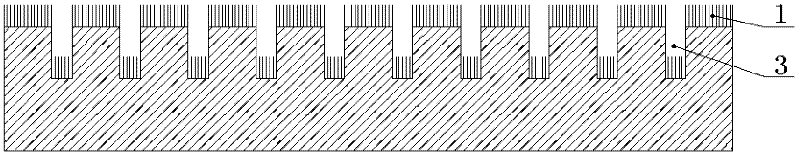

[0040] see figure 2 and image 3 , figure 2 It is a schematic diagram of the product structure obtained according to Embodiment 2 of the present invention. Its specific manufacturing process includes:

[0041] (a) AZ5214 photoresist is coated on the single crystal silicon wafer after surface cleaning, and the micro-scale pattern on the mask is transferred to the photoresist by photolithography process. The photoresist pattern is a microhole array That is, micron-scale hole array structure;

[0042] (b) Coating a 30nm silver film on the entire monocrystalline silicon wafer by a magnetron sputtering process;

[0043] (c) Use acetone to ultrasonically clean the silicon wafer for 10 minutes to remove the photoresist;

[0044] (d) using hydrogen fluoride and H 2 o 2 The mixed solution is used as an etchant to perform metal-catalyzed etching on a single crystal silicon wafer, thereby corroding a silicon micropore array structure, that is, a micron-scale micropore array stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com