Suspension for producing a layer increasing the coefficient of friction, molded part having such a layer increasing the coefficient of friction, method for the production thereof, and use thereof

一种增大摩擦、悬浮体的技术,应用在摩擦夹紧的可卸紧固件、摩擦衬片、机械设备等方向,能够解决低温度稳定性等问题,达到高粘附摩擦系数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

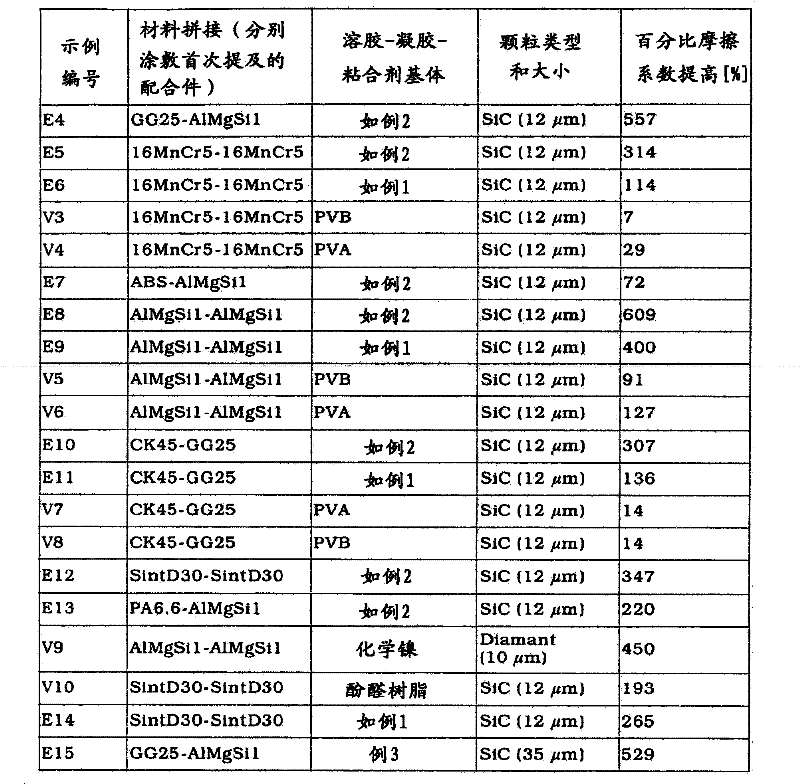

Examples

example 1

[0109] Example 1: SiC with ethanolated 2 - Coating of sol-gel-adhesive and hard material SiC

[0110] Mix 87g BaSO 4 (Sachtoperse HU-N from the company Sachtleben) was mixed into 783 g of the binder Inosil SB (Inomat GmbH) and subsequently dispersed with an Ultra-Turrax (IKA company) for 10 minutes.

[0111] Average particle size d 50 = 12μm and d 97 - 130 g of SiC powder with a value of 22 μm is mixed into a mixture of binder and BaSO 4 Make up the premix for an hour. The binder is made with SiO 2 - Nanoparticles of SiO 2 - Sol-gel-nanocomposite formation, which is surface-modified with hydrolyzable residues of silanes. The suspension was applied with a HVLP applicator gun. After drying the coating at room temperature the layer was calcined at 350° C. for 30 minutes. After calcination, the average matrix layer thickness was about 5 μm and the surface coverage with SiC particles was about 20% as determined by optical microscopy.

example 2

[0112] Example 2: Boehmite-SiO with binder 2 -Coating of sol and hard material SiC

[0113] Heat 500ml of water to 85°C to 95°C. 34 g of nanoscale boehmite powder were then added under vigorous stirring. Homogenization was performed within 10 minutes with vigorous stirring. The suspension was gelled with 6 ml of concentrated nitric acid at process temperature. No aging step at elevated temperature was performed. The sol is concentrated during the manufacturing process. The sol was diluted by adding water to a boehmite solids content of 7.1% by weight (corresponding to a content of 8.3 g of hydrated boehmite powder). 500 g of Dynasylan Sivo 110 (Evonik Degussa) were stirred into 500 g of cold boehmite sol.

[0114] Average particle size d 50 = 12μm and d 97 - 80 g of SiC powder with a value of 22 μm are mixed in 920 g of a premix consisting of boehmite sol and Dynasylan Sivo 110 for one hour.

[0115] The suspension was applied with a HVLP applicator gun. The la...

example 3

[0116] Example 3: SiO with ethanol 2 - Coating of sol-gel-adhesive and hard material SiC

[0117] 40 g of HDK N20 (fumed silica, Wacker-Chemie AG) were mixed in 830 g of binder Inosil SB (Inomat AG) with a stirring assembly and subsequently dispersed with an Ultra-Turrax (IKA company) for 60 minutes.

[0118] Average particle size d 50 = 35μm and d 97 - 130 g of SiC powder with a value of 60 μm are mixed into the premix consisting of binder and HDK N20 for one hour. The binder is made with SiO 2 - Nanoparticles of SiO 2 - Sol-gel-nanocomposite formation, which is surface-modified with hydrolyzable residues of silanes. The suspension was applied with a HVLP applicator gun. The layer was tempered at 100° C. for 30 minutes after drying the coating at room temperature. The average base layer thickness was about 8 μm, and the surface coverage with SiC particles was about 20% as determined by optical microscopy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com