A step-by-step method for preparing microfibrillar collagen using gradient polarity of ionic liquids

An ionic liquid and microfiber technology, applied in the field of biological material preparation, can solve the problems of loss of biological activity, difficult removal, toxicity, etc., and achieve the effects of ensuring biological activity, reducing industrialization costs, and reducing usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

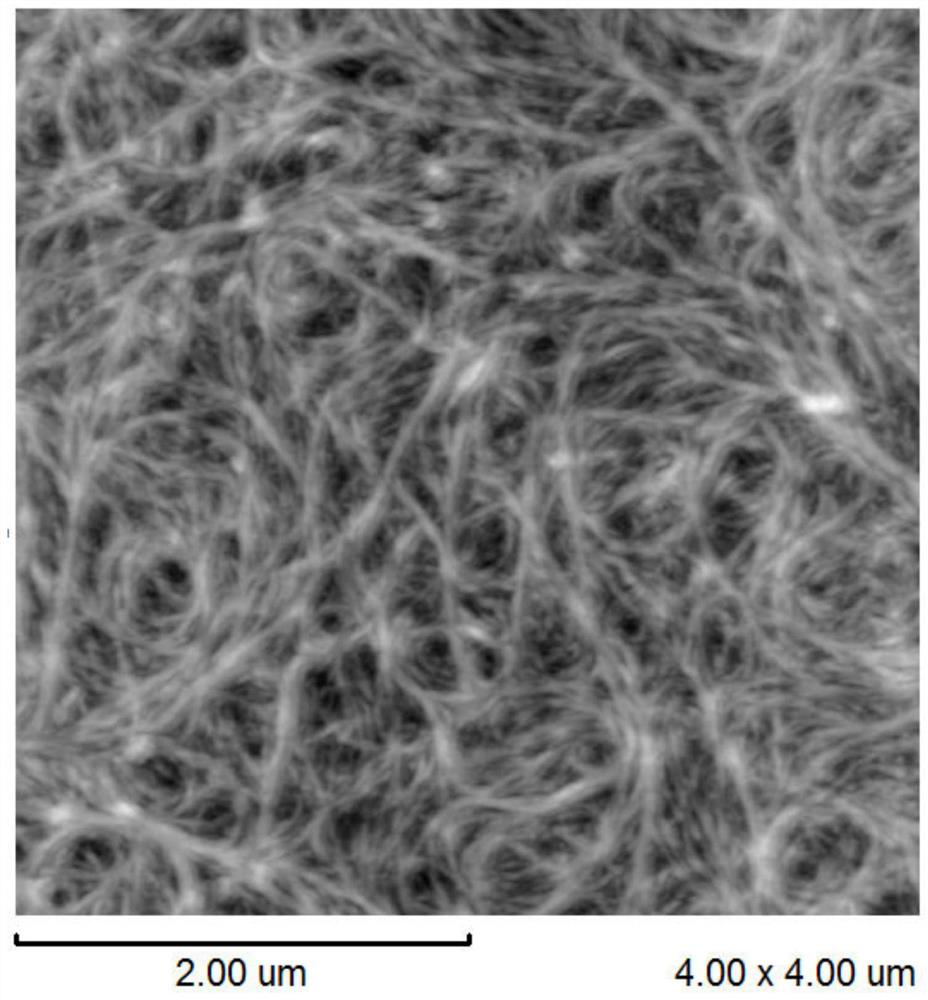

Image

Examples

Embodiment 1

[0057] (1) Raw material pretreatment

[0058] In parts by weight, add 1000 parts of cowhide to 5000 parts of isopropanol, shake for 10 hours, remove isopropanol after the time is up, then mix with 1500 parts of water and 0.2 part of DTM198 enzyme, and use Na 2 CO 3Adjust the pH to 9.0, stir for 30 minutes, stand still, stir for 1-2 minutes every 1 hour, and filter the solid product after standing for a total of 16 hours, then add the solid product to 3000 parts of peroxide with a mass concentration of 60g / L Hydrogen, the role of 4.5h, as the raw material of microfibril collagen.

[0059] (2) Step-by-step ionic liquid treatment

[0060] Chop the raw material of microfibril collagen into blocks with a diameter of 10 mm, immerse it in a solution of 1-ethyl-3-methylimidazolium acetate with a mass concentration of 30%, and stir at a temperature of 4-15°C for 13 hours After the action time is up, centrifuge to take the precipitate and wash it, then mechanically cut it into a bloc...

Embodiment 2

[0066] (1) Raw material pretreatment

[0067] In parts by weight, add 1000 parts of pigskin to 5200 parts of isopropanol, shake for 11 hours, remove isopropanol after the time is up, then mix with 1550 parts of water and 0.25 parts of DTM198 enzyme, and use Na 2 CO 3 Adjust the pH to 9.1, stir for 35 minutes, stand still, stir for 1 minute every 1 hour, and filter the solid product after standing for a total of 16 hours, then add the solid product to 3100 parts of hydrogen peroxide with a mass concentration of 60g / L , The role of 4.5h, as a raw material for microfibril collagen.

[0068] (2) Preparation of microfibril collagen

[0069] Chop the raw material of microfibril collagen into blocks with a diameter of 10 mm, immerse it in a solution of 1-butyl-3-methylimidazole dinitrile amine salt with a mass concentration of 70%, and stir it at a temperature of 4-15 ° C After 11 hours, after the action time is up, centrifuge to take the precipitate and wash it, then mechanically...

Embodiment 3

[0075] (1) Raw material pretreatment

[0076] In parts by weight, add 1000 parts of sheepskin to 5400 parts of isopropanol, shake for 12 hours, remove isopropanol after the time is up, then mix with 1540 parts of water and 0.22 parts of DTM198 enzyme, and use Na 2 CO 3 Adjust the pH to 9.0, stir for 35 minutes, stand still, stir for 2 minutes every 1 hour, and filter the solid product after standing for a total of 16 hours, then add the solid product to 3000 parts of hydrogen peroxide with a mass concentration of 60g / L , The role of 4.5h, as a raw material for microfibril collagen.

[0077] (2) Preparation of microfibril collagen

[0078] Mince the raw material of microfibrous collagen into blocks with a diameter of 10 mm, immerse it in a solution of 1-ethyl-3-methylimidazolium tetrafluoroborate with a mass concentration of 50%, and stir at a temperature of 4-15°C After 8 hours of action, after the action time is up, centrifuge to take the precipitate and wash it, then mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com