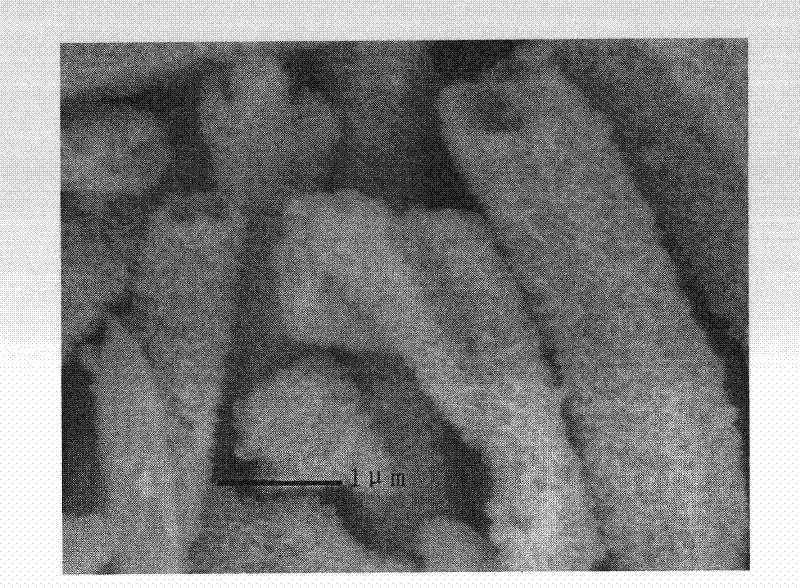

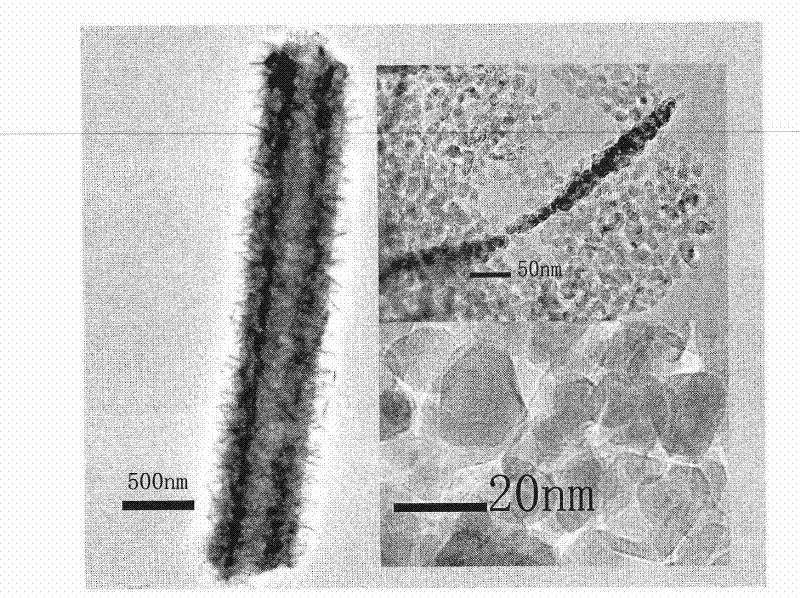

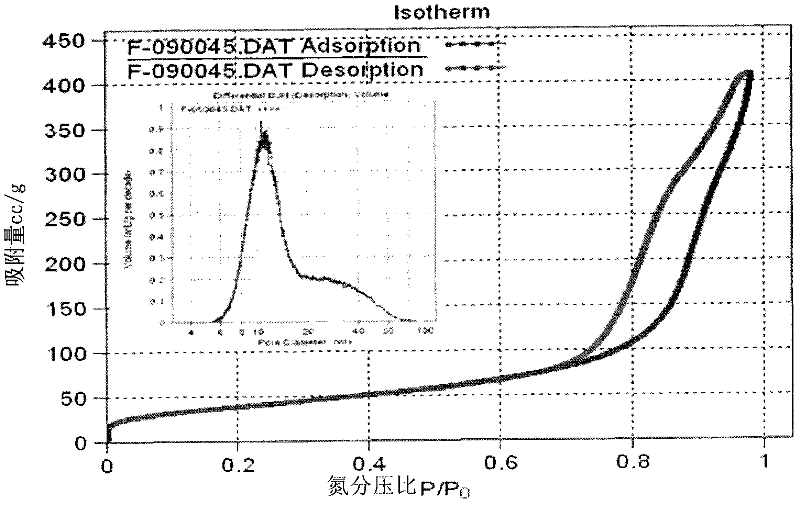

Titanium oxide micro-nanotube with visible-light catalysis effect, and preparation method thereof

A catalytic effect, titanium oxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as easy agglomeration, reduced photocatalyst activity, and failure to effectively utilize solar visible light, etc. Achieve the effect of scientific preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The concrete steps of preparation are:

[0030] Step 1: first mix titanyl sulfate hydrate, methanol and glycerin according to a molar ratio of 1:15:60, and then stir for 1 min to obtain a mixed solution. Then add diethyl ether to the mixed solution and stir for 1 min; wherein, the molar ratio between the diethyl ether and the hydrated titanyl sulfate in the mixed solution is 7:1 to obtain a precursor solution.

[0031] In step 2, first place the precursor solution in an airtight state, react at 105°C for 40 hours, and then cool to room temperature to obtain a gel. Then add ethanol to the gel and stir for 1 min; wherein, the molar ratio between ethanol and hydrated titanyl sulfate in the gel is 20:1 to obtain a gel mixture. Then, the gel mixture was subjected to ultrasonication, centrifugation, washing and drying; wherein, the time of ultrasonic treatment was 2min, the rotational speed of centrifugal treatment was 3500r / min, and the time was 3min. For drying at 75°C fo...

Embodiment 2

[0034] The concrete steps of preparation are:

[0035] Step 1: first mix titanyl sulfate hydrate, methanol and glycerin according to a molar ratio of 1:16:65 and then stir for 2 minutes to obtain a mixed solution. Then add diethyl ether to the mixed solution and then stir for 2 min; wherein, the molar ratio between the diethyl ether and the hydrated titanyl sulfate in the mixed solution is 8:1 to obtain a precursor solution.

[0036] In step 2, first place the precursor solution in an airtight state, react at 108°C for 34 hours, and then cool to room temperature to obtain a gel. Then add ethanol to the gel and stir for 1 min; wherein, the molar ratio between ethanol and hydrated titanyl sulfate in the gel is 23:1 to obtain a gel mixture. Then, the gel mixture was subjected to ultrasonication, centrifugation, washing and drying; wherein, the time of ultrasonic treatment was 3min, the rotational speed of centrifugal treatment was 3800r / min, and the time was 3min, and the washin...

Embodiment 3

[0039] The concrete steps of preparation are:

[0040] Step 1: first mix titanyl sulfate hydrate, methanol and glycerin according to a molar ratio of 1:17.5:70, and then stir for 3 minutes to obtain a mixed solution. Then add diethyl ether to the mixed solution and stir for 3 minutes; wherein, the molar ratio between the diethyl ether and the hydrated titanyl sulfate in the mixed solution is 8.5:1 to obtain a precursor solution.

[0041] In step 2, first place the precursor solution in a closed state, react at 110° C. for 28 hours, and then cool to room temperature to obtain a gel. Then add ethanol to the gel and stir for 1.5 min; wherein, the molar ratio between ethanol and titanyl sulfate hydrate in the gel is 25:1 to obtain a gel mixture. Then, the gel mixture was subjected to ultrasonication, centrifugation, washing and drying; wherein, the time of ultrasonic treatment was 3.5min, the rotational speed of centrifugal treatment was 4000r / min, and the time was 2min. Treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com