Self-assembled copolymerized carbon nitride photocatalytic composite material and its preparation method and application

A composite material and self-assembly technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor preparation efficiency, high cost of raw materials, and limited application range of graphite phase carbon nitride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

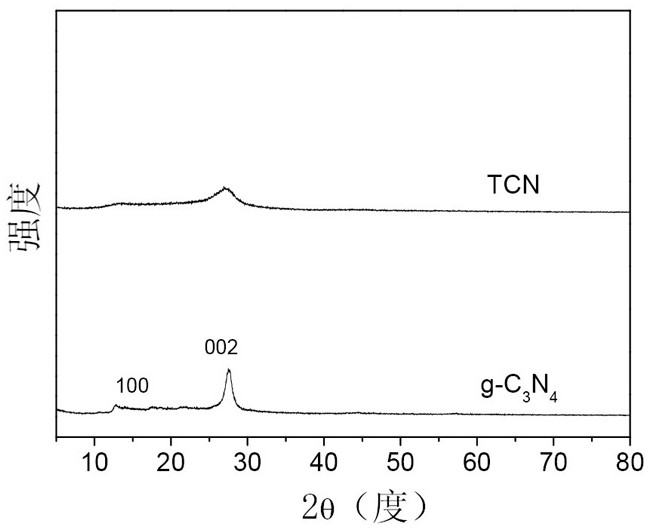

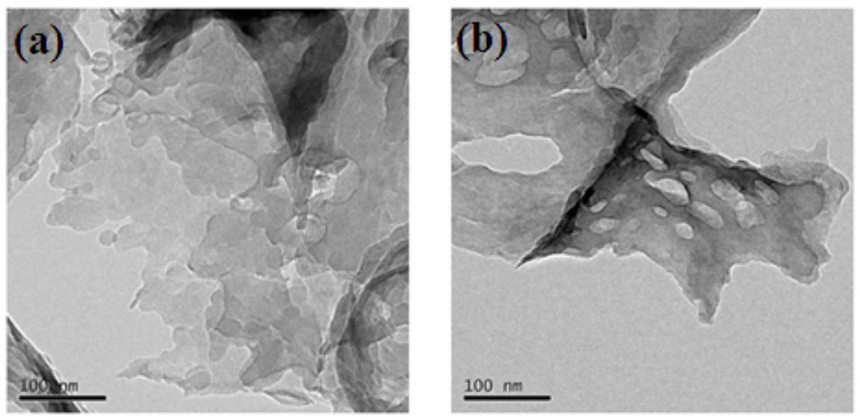

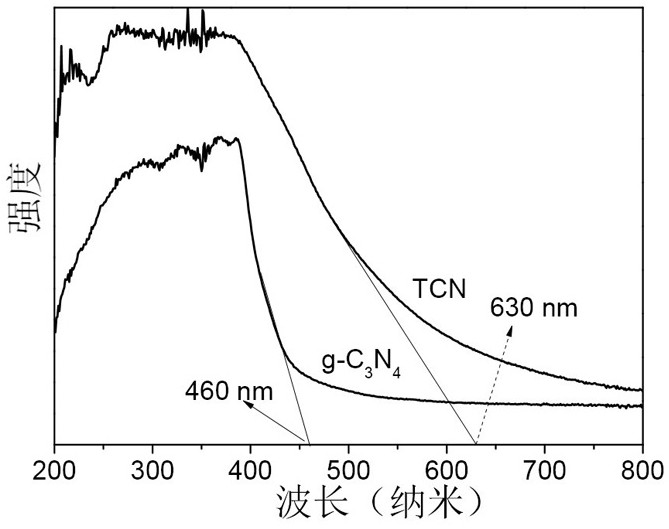

[0034] A self-assembled copolymerized carbon nitride photocatalytic composite material is prepared by calcining urea and thiobarbituric acid as raw materials. The mass ratio of urea and thiobarbituric acid is 1:0.02. The preparation method includes The following steps:

[0035] Take 10g of urea and 0.2g of thiobarbituric acid, grind them, dissolve them in 100mL of water, stir for 2h, and dry them on an electric furnace (at 80°C for 10h) to obtain a precursor. Put the precursor into a quartz crucible and place the quartz crucible in a muffle furnace, cover it, and perform calcination under normal conditions (that is, without protective gas), specifically: heating to 400 °C at a heating rate of 5 °C / min ℃, keep it at 400°C for 1 hour, continue heating to 550°C at a heating rate of 5°C / min, keep it at 550°C for 3 hours, take out the block after natural cooling, and grind it for 20 minutes to obtain self-assembled copolymerized carbon nitride light The catalytic composite materia...

Embodiment 2

[0043] An application of a self-assembled copolymerized carbon nitride photocatalytic composite material in degrading organic pollutants, specifically utilizing the self-assembled copolymerized carbon nitride photocatalytic composite material to degrade organic pollutants in water bodies, comprising the following steps:

[0044] Take the self-assembled copolycarbon nitride photocatalytic composite (TCN) prepared in Example 1 and the carbon nitride photocatalyst material (g-CN) prepared in Comparative Example 1 3 N 4 ), each 100mg, respectively placed in 100mL tetracycline solution with a concentration of 10mg / L, stirred in a dark environment (dark room) for 60 minutes to reach adsorption equilibrium, and then placed in a visible light source (xenon lamp) for photocatalytic reaction to complete the Degradation of organic pollutants in water bodies.

[0045] During the photocatalytic reaction, 4 mL of tetracycline solution was taken every 10 minutes, and the characteristic peak...

Embodiment 3

[0048] An application of a self-assembled copolymerized carbon nitride photocatalytic composite material in degrading organic pollutants, specifically utilizing the self-assembled copolymerized carbon nitride photocatalytic composite material to degrade organic pollutants in water bodies, comprising the following steps:

[0049] Take the self-assembled copolycarbon nitride photocatalytic composite (TCN) prepared in Example 1 and the carbon nitride photocatalyst material (g-CN) prepared in Comparative Example 1 3 N 4 ), each 100 mg, respectively placed in 100 mL of sulfamethazine solution with a concentration of 10 mg / L, stirred in a dark environment (dark room) for 60 minutes to reach adsorption equilibrium, and then placed in a visible light source (xenon lamp) for photocatalysis reaction to complete the degradation of organic pollutants in water.

[0050] During the photocatalytic reaction process, take 4mL sulfamethazine solution every 10 minutes, measure the characteristi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com