Hydrogenation catalyst, preparation method and application thereof as well as hydrofining method

A hydrogenation catalyst and hydrogenation refining technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low hydrogenation catalyst activity, achieve high hydrodesulfurization activity, reduce Effect of energy consumption and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The invention provides a method for preparing a hydrogenation catalyst, the method comprising successively loading a first compound and a second compound on a carrier, wherein the first compound is a heteropolyacid with a Group VIB metal as a coordination atom and / or heteropoly acid salt, the second compound is a non-metal oxo acid salt with Group VIII metal as cation and / or anaerobic acid salt with Group VIII metal as cation, the method also includes: Between the first compound and the second compound, the carrier loaded with the first compound and NH 3 contacting; or between loading the first compound and the second compound, loading the quaternary ammonium salt and / or amine on the carrier loaded with the first compound.

[0015] Group VIB metals and Group VIII metals are the active components of hydrogenation catalysis, therefore, the loading form of Group VIB metals and Group VIII metals on the support has a significant impact on the hydrogenation activity of the f...

Embodiment 1

[0085] This example is used to illustrate the hydrogenation catalyst and its preparation method according to the present invention.

[0086] Take by weighing 10000 grams of aluminum hydroxide powder (70% by weight on a dry basis, purchased from Sinopec Changling Catalyst Branch) and 4000 grams of silica sol (containing 25% by weight of silicon dioxide, purchased from Qingdao Ocean Chemical Plant), mix them with an extrusion Strip machine (manufacturer: South China University of Technology Science and Technology Industrial General Factory, model: F-26(Ⅲ)) was extruded into a clover-shaped strip with a circumscribed circle diameter of 1.4 mm, then dried at 120°C for 10 hours, and roasted at 600°C for 3 hours. Vector S1 is obtained. The content of silicon oxide in support S1 was 12.5% by weight and that of aluminum oxide was 87.5% by weight.

[0087] Weigh 200 grams of carrier S1, impregnate the carrier with 170 milliliters of aqueous solution containing 14.0 grams of ammonium...

Embodiment 2

[0090] This example is used to illustrate the hydrogenation catalyst and its preparation method according to the present invention.

[0091] Take 200 grams of carrier S1 prepared in Example 1, impregnate with 170 ml of aqueous solution containing 17.5 grams of ammonium fluoride for 2 hours, then dry at 120°C for 4 hours, and bake at 480°C for 3 hours to obtain fluorine-containing carrier S1-2.

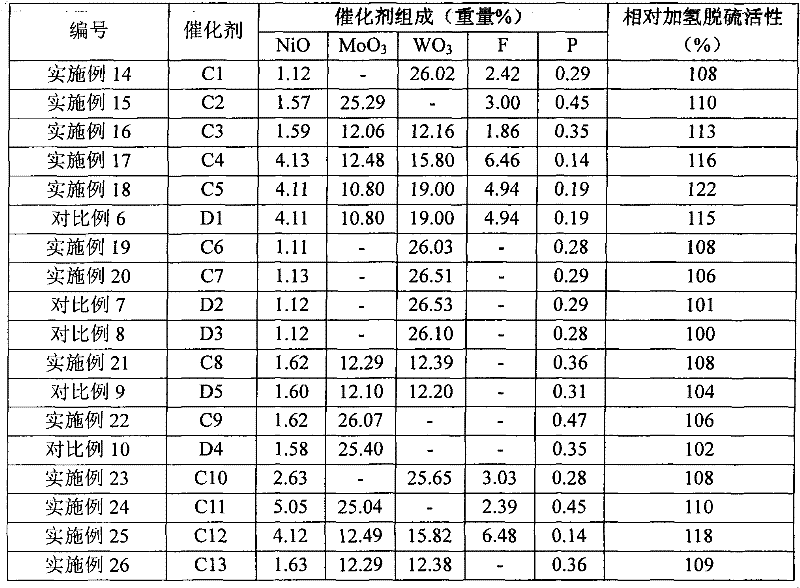

[0092] With 167 milliliters of aqueous solutions containing 76.69 grams of phosphomolybdic acid and 12.11 grams of urea, impregnate the above-mentioned fluorine-containing carrier S1-2 for 2 hours, then dry at 140° C. for 4 hours; 163 ml of an aqueous solution (with a nickel content of 20% by weight in terms of elements) was impregnated with the carrier for 2 hours, and then dried at 180° C. for 5 hours to obtain catalyst C2. The composition of catalyst C2 after calcination at 550° C. for 4 hours is listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com