Method for preparing layered zeolite with MWW structure

A layered zeolite and mixture technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of potential safety hazards, template agent storage, transportation, high cost of use and management, etc., to reduce dosage, shorten crystallization time, and improve production speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

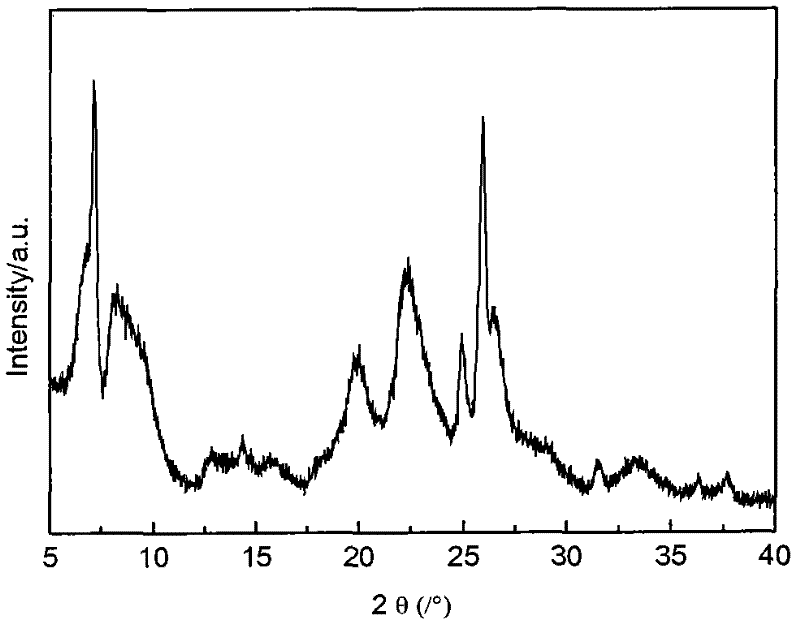

[0028] The synthetic process of the present invention is as follows: take by weighing 150 grams (1 mole) of silica sol (40% by weight), 30 grams (0.05) of aluminum sec-butoxide, 75 grams of dimethyl diethyl ammonium hydroxide (20% by weight) aqueous solution ( 0.1 mole), 11.6 grams (0.2 moles) of sodium chloride, 4 grams (0.1 moles) of sodium hydroxide, 8 grams of seed crystals, and 50 grams of distilled water were mixed and stirred for 18 hours, and the slurry mixture was poured into the crystallization kettle , moved into an oven for crystallization at 140°C for 4 days, took out the product, filtered, washed, and the XRD powder diffraction spectrum detection of the dried product determined that the zeolite microcrystal was a zeolite with a layered WMM structure. The specific X-ray diffraction spectrum is shown in the attached figure 1 , and its XRD spectrum has a dissociation peak at 7°-11°, indicating that the product prepared by the present invention is a layered zeolite wi...

Embodiment 2~9

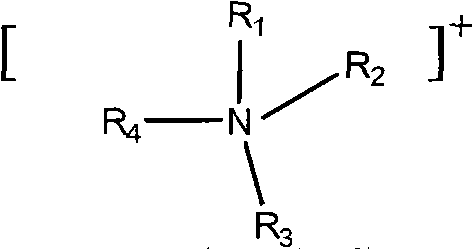

[0034] The synthesis steps and methods of [Examples 2-9] are the same as [Example 1], except that the types and proportions of raw materials, crystallization temperature, crystallization time, templating agent, seed crystals and proportions are changed. The synthesized zeolite product was determined by XRD powder diffraction spectrum detection. The zeolite microcrystal is a layered zeolite with a similar MWW topology. The specific X-ray diffraction spectrum and the attached figure 1 unanimous. The specific data are the same as in Table 1. Template agent: The molecular formula of the template agent obtained according to the different values of m, n, k, and l in the general formula of the template agent is represented by different English letters, as shown in Table 2. The ratio of raw materials for the synthesis system is shown in Table 3.

[0035] In this method, during the preparation of layered zeolite molecular sieves, unequal tetraalkylammonium cations are used to repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com