Recovery process of phenylacetic acid

A technology of phenylacetic acid and process, applied in the field of recovery technology of phenylacetic acid, can solve problems such as environmental pollution, waste of resources, and difficulty in recovery, and achieve the effects of simple operation, reduced pollution, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

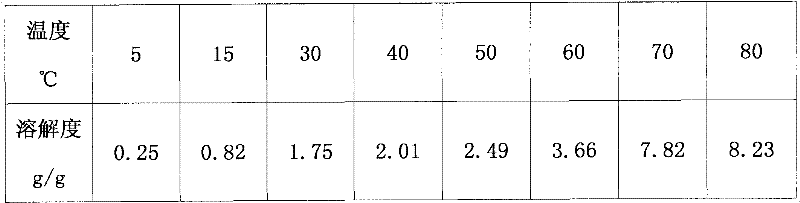

[0010] The present invention utilizes the extraction method to reclaim the phenylacetic acid in the pharmaceutical waste water, and the technological step of the present invention is: take 1000mL waste liquid and pack in the three-necked flask, adjust pH value 2.0~3.0 with 20% hydrochloric acid, add extractant, temperature Control at 5-80°C, stop stirring for 20-30 minutes, transfer the mixed solution into a separatory funnel, and let it stand for stratification; take the organic phase, adjust the pH value to 9.0-9.5 with sodium hydroxide, and transfer it into a separatory funnel Stand to separate and separate the organic phase; heat the water phase to 50-60°C, add 5-25g of activated carbon for decolorization, and filter; cool the filtrate, while stirring, add 20% hydrochloric acid dropwise to pH 2.0-3.0, crystals; white flaky crystals were obtained by suction filtration, weighed after drying, calculated the yield, and detected the content of phenylacetic acid.

[0011] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com