Method for culturing marine green alga accumulated starch with carbon dioxide

A technology of marine green algae and green algae, applied in chemical instruments and methods, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of high starch production costs and reduce production costs, and achieve good sustainability, Environmentally friendly, realize the effect of CO2 emission reduction and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

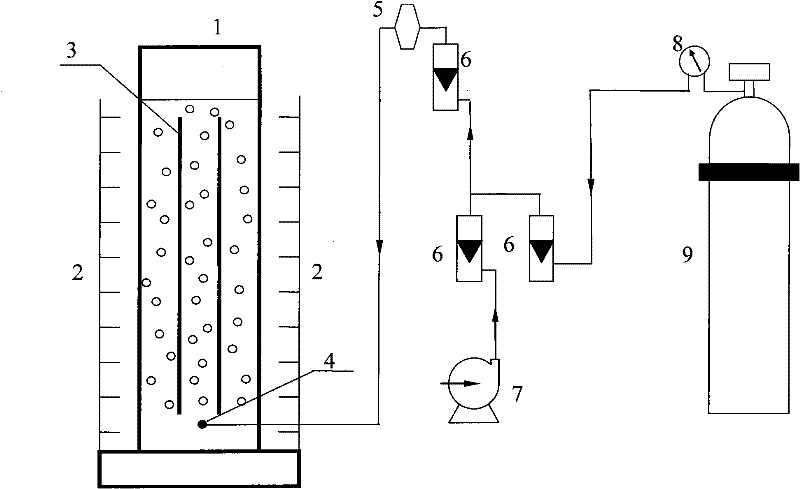

Method used

Image

Examples

Embodiment 1

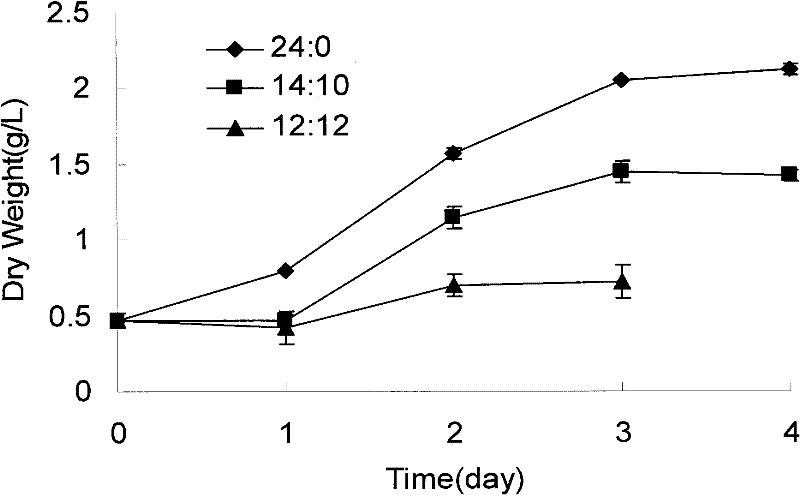

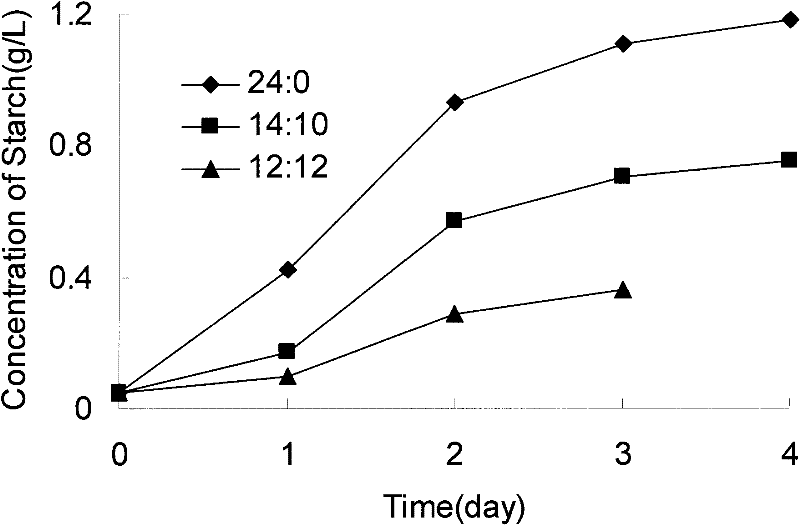

[0031] The effect of light-dark cycle on algal cell growth and starch accumulation was investigated. Tetraselmis subcordiformis was provided by Dalian Fisheries Research Institute of Liaoning Province, and was purified by plate in our laboratory.

[0032] 1) Obtaining algae cell seed solution

[0033] Preparation of nutrient salt mother solution: prepare 1000 times nutrient salt mother solution with deionized water, the formula is: NaNO 3 100g / L, NaH 2 PO 4 2H 2 O 20.0g / L, EDTA-Na 2 45.0g / L,H 3 BO 3 33.6g / L, MnCl 2 4H 2 O 0.36g / L, FeCl 3 ·6H 2 O 1.3g / L, ZnCl 2 0.21g / L, CoCl 2 ·6H 2 O 0.20g / L, (NH 4 ) 4 Mo 7 o 24 4H 2 O 0.09g / L, CuSO 4 ·5H 2 O 0.20g / L. Sterilize by high pressure steam at 110°C for 15 minutes, and cool down for later use.

[0034] Preparation of algae culture medium: natural seawater was filtered through a microfiltration membrane with a pore size of 0.3 μm. Add 1mL of the above nutrient salt mother solution to every liter of filtered ...

Embodiment 2

[0044] Investigate the initial KNO 3 Concentration effects on algal cell growth and starch accumulation. Tetraselmis subcordiformis was provided by Dalian Fisheries Research Institute of Liaoning Province, and was purified by plate in our laboratory.

[0045] The preparation of the algae cell seed liquid and the preparation of the nitrogen-free nutrient salt mother liquid are the same as in "Example 1".

[0046] Preparation of culture medium: Artificial seawater was filtered through a microfiltration membrane with a pore size of 0.3 μm. The artificial seawater formula is: NaCl 27g / L, MgSO 4 ·7H 2 O 6.6g / L, MgCl 2 ·6H 2 O 5.6g / L, CaCl 2 2H 2 O 1.5g / L, NaHCO 3 0.04g / L. Add 1mL of nitrogen-free nutrient salt mother solution to every liter of filtered seawater. Sterilize by high pressure steam at 110°C for 15 minutes, and cool down for later use.

[0047] Cultivation of algae cells: The sterilized reactor is soaked in NaClO, cleaned with sterile water, and inserted int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com