Low-concentration nickel-plating technology for permanent magnet material

A permanent magnet material and low-concentration technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of difficult wastewater treatment, high concentration, high cost, etc., and achieve strong impurity resistance and coating binding force Good, low porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

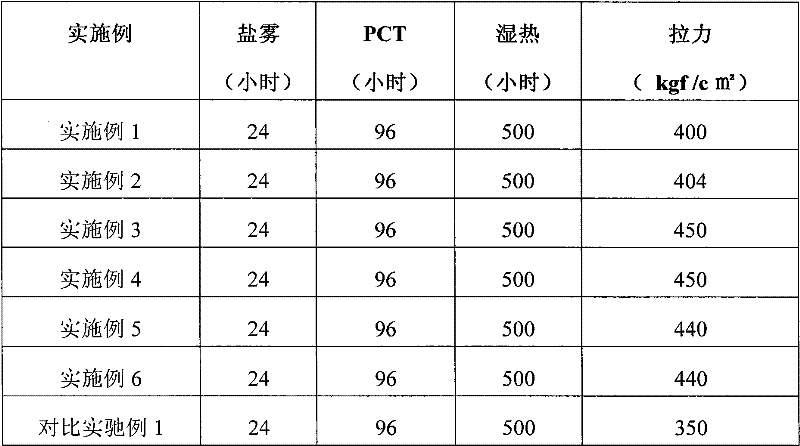

[0017] Grind 2.3 kg of ¢24*¢15*18mm sintered NdFeB permanent magnet material in a vibrating mill for 2 hours. After degreasing and degreasing by sodium phosphate 20g / L, sodium carbonate 10g / L, and sodium hydroxide 10g / L, pickled in 1% nitric acid to remove surface oxides, and washed with water. Nickel sulfate 30 g / L, sodium chloride 12 g / L, boric acid 45 g / L. Among them, the pH was 5.0, the thickness of the nickel layer was 3 microns, and the grain size was 20 nanometers. Then, the salt spray test, damp heat test and tensile test were carried out, and the corrosion resistance was good, see Table 1.

Embodiment 2

[0019] 2.5 kg of ¢24*¢15*18mm bonded NdFeB permanent magnet material was polished according to the method of Example 1, degreased and degreasing, and pickled. Nickel sulfate 80 g / L, sodium chloride 15 g / L, boric acid 30 g / L. Among them, the pH is 4.0, the grain size is 200 nanometers, and the thickness is 10 micrometers. Then, the salt spray test, damp heat test and tensile test were carried out, and the corrosion resistance was good, see Table 1.

Embodiment 3

[0021] 2.5 kg of ¢24*¢15*18mm sintered NdFeB permanent magnet material was polished according to the method of Example 1, degreased and degreasing, and pickled. Nickel sulfate 40 g / L, sodium chloride 14 g / L, boric acid 40 g / L. Among them, the pH was 4.5, the thickness of the nickel layer was 5.5 microns, and the grain size was 80 nanometers. Then, the salt spray test, damp heat test and tensile test were carried out, and the corrosion resistance was good, see Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com