Low-impedance electrically-controlled line for touch panel, and manufacturing method for low-impedance electrically-controlled line

A technology of touch panel and manufacturing method, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of yield reduction, disconnection, uneven line impedance, etc., so as to achieve less loss and increase The overall stability and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail by means of the following specific embodiments and accompanying drawings, as follows:

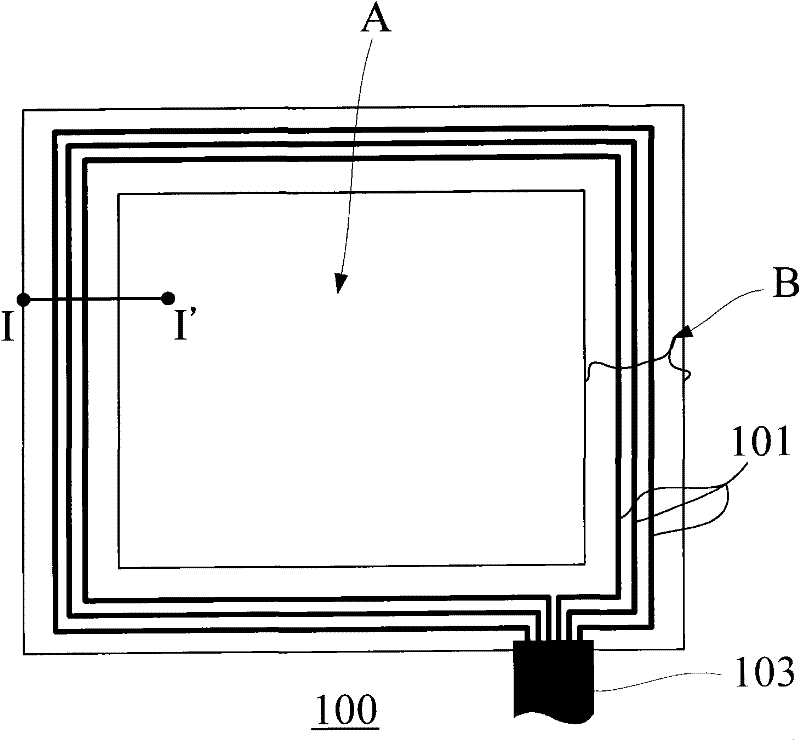

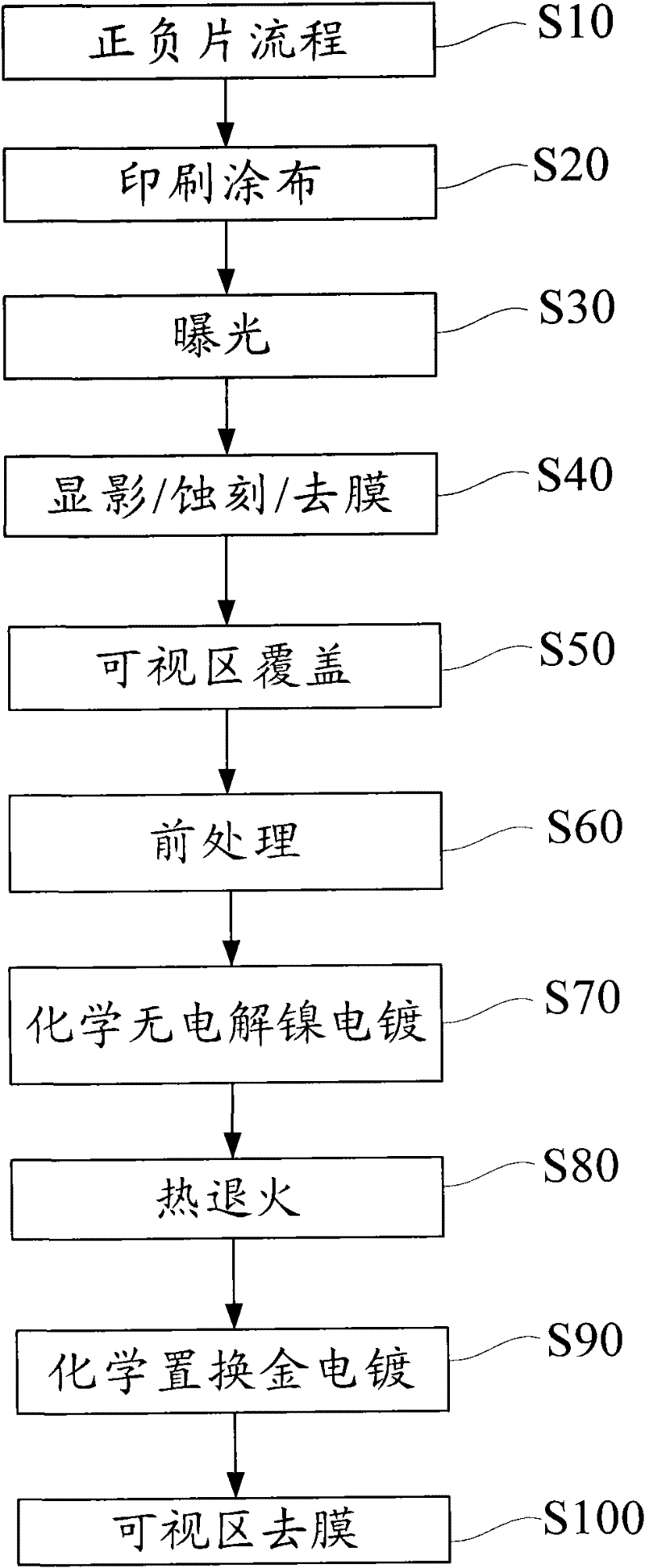

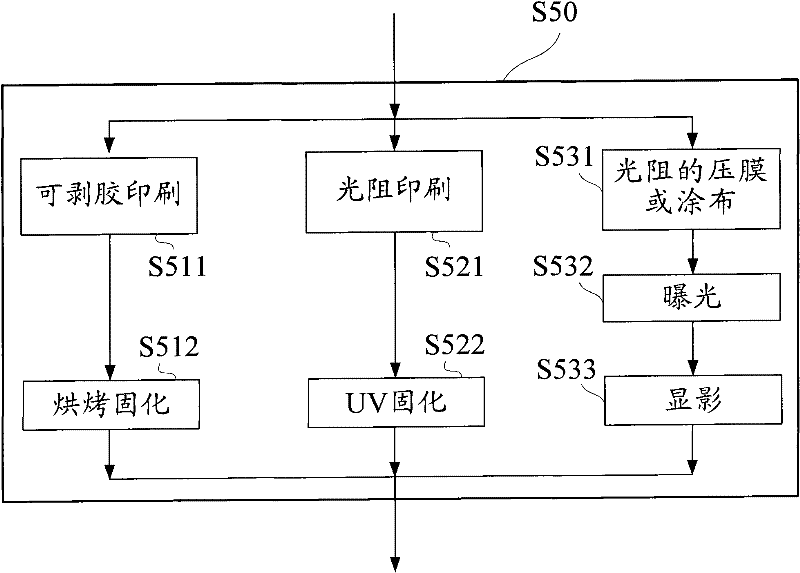

[0030] The low-impedance circuit layer added to the original electronic control circuit in the present invention is different from the low-impedance circuit layer formed by silver glue printing method, molybdenum / aluminum / molybdenum sputtering method and copper electroplating sputtering method. It is known that the exposure / development / etching process carried out on the non-visible area on the substrate makes the transparent conductive layer into an indium tin oxide electronic control circuit. The present invention further performs subsequent method steps for reducing the surface resistance of the electronic control circuit, which is simplified In other words, the present invention adds nickel and gold to the indium tin oxide electronic control cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com