Preparation method for high-purity nanometer-type poly-hydroxy zirconium chloride sol

A polyhydroxyzirconium chloride, nano-type technology, applied in the direction of zirconium halide, nanotechnology, etc., can solve the problems of harsh hydrolysis conditions, cumbersome process, high raw material cost, etc., and achieve the effect of ensuring nano characteristics, high purity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

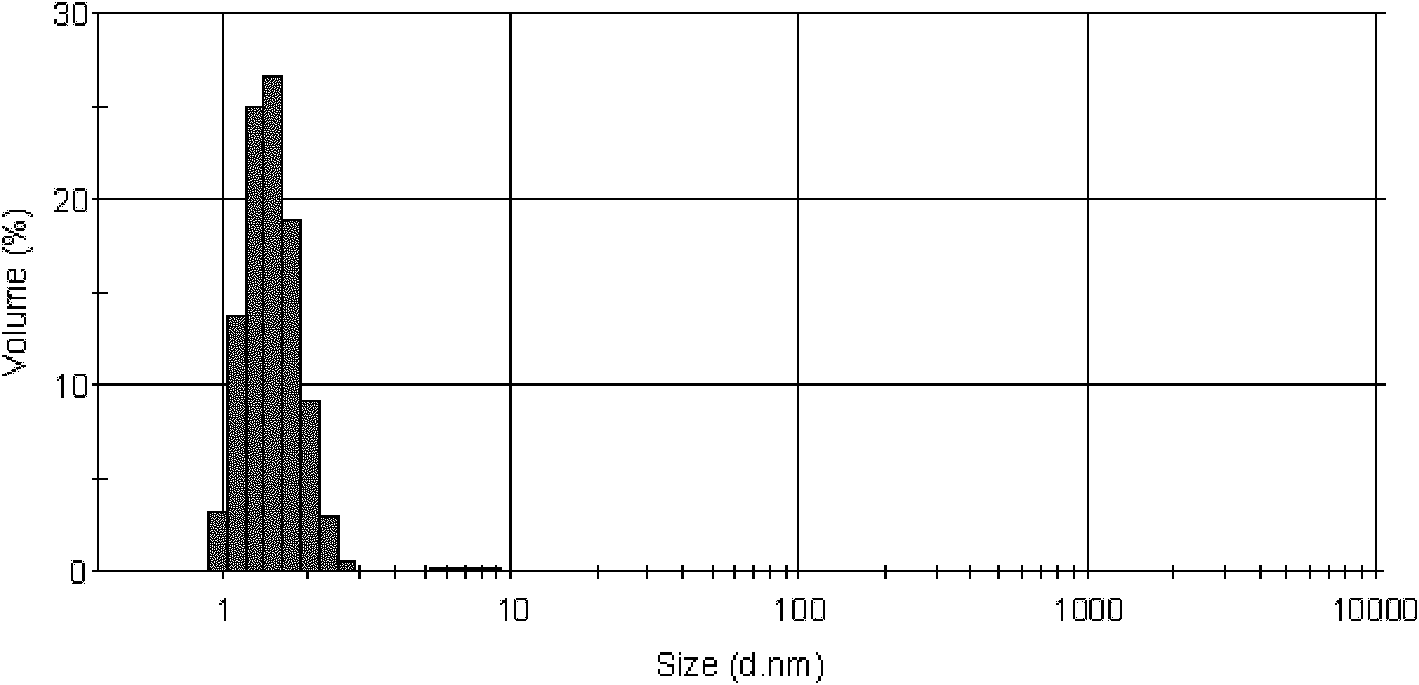

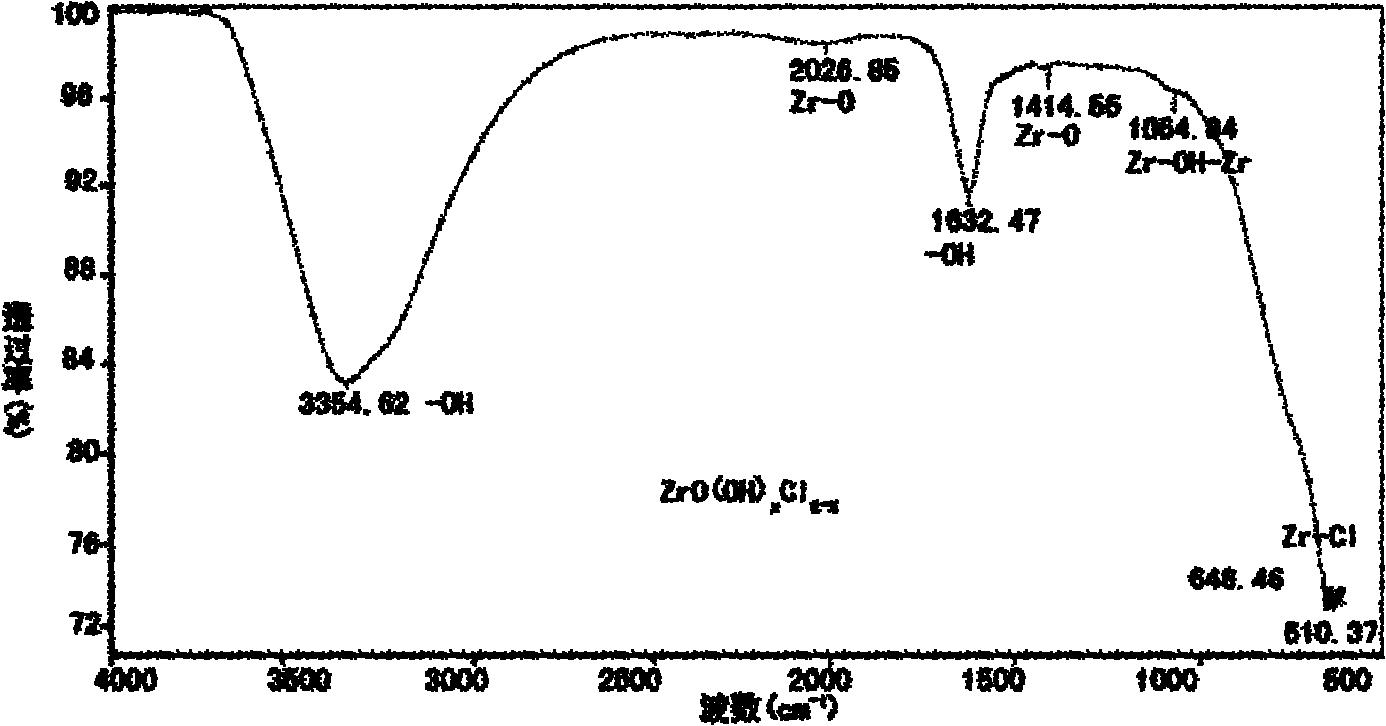

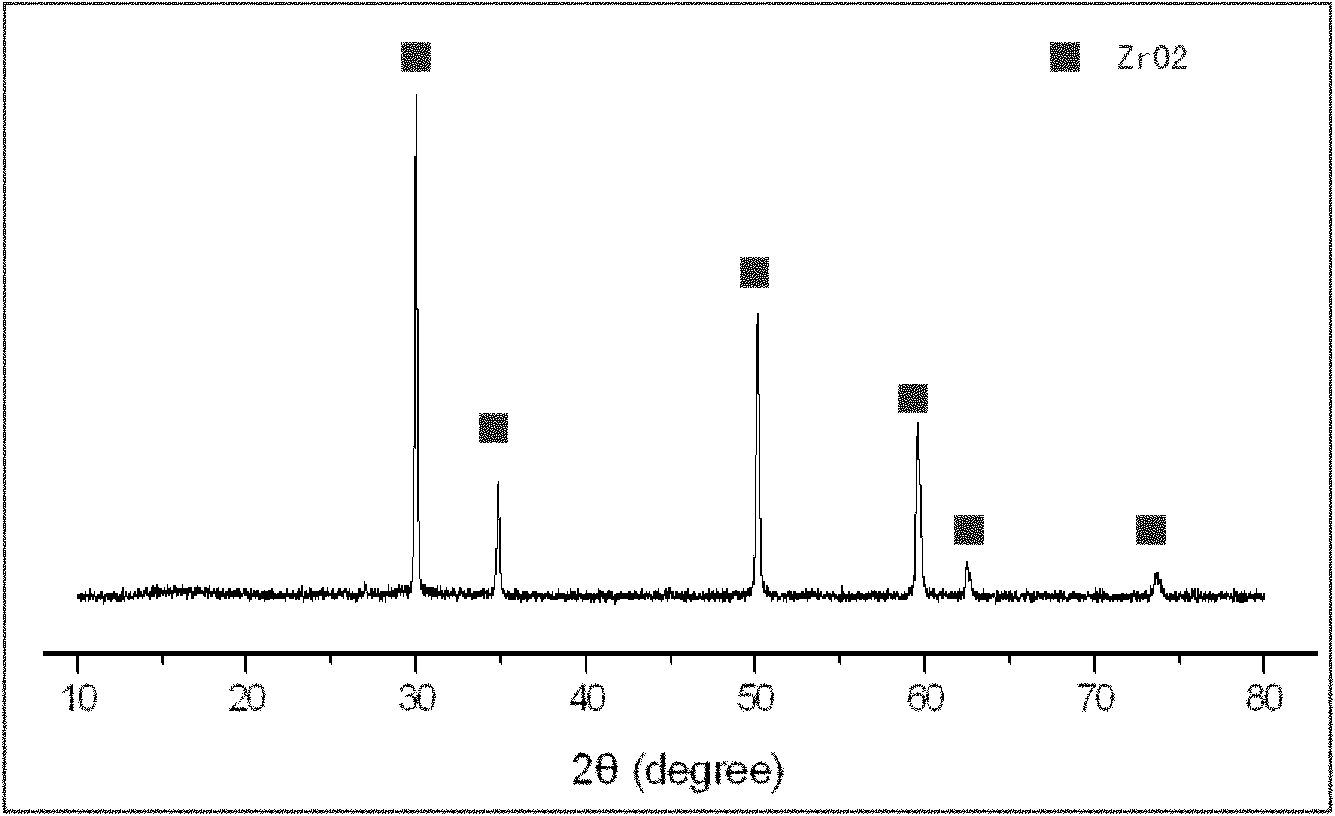

[0027] Put 617g of zirconium carbonate powder in water to form a suspension, filter to remove impurities and set aside. Weigh 117g of industrial hydrochloric acid with a concentration of 31wt%, dilute it to 10wt%, add it to the reflux device, and heat up to 50°C; add the zirconium carbonate powder treated above into the hydrochloric acid solution, stir and heat to 80°C until completely dissolved ; Add 25g yttrium chloride, further reflux hydrolysis, until the solution is completely clear and transparent. The solution was distilled under reduced pressure at 80° C. and dehydrated to a concentration of 25 wt % to obtain the final colloid. The particle size distribution of the obtained colloid is shown in figure 1 , and the infrared spectrum after drying is shown in figure 2 , the XRD pattern after calcination at 1000°C is shown in image 3 .

Embodiment 2

[0029] Put 174g of zirconium carbonate powder in water to form a suspension, filter to remove impurities and set aside. Weigh 50g of industrial hydrochloric acid with a concentration of 31wt%, dilute it to 10wt%, add it to the reflux device, and heat up to 50°C; add the zirconium carbonate powder treated above into the hydrochloric acid solution, stir and heat to 70°C until completely dissolved ; Add 10.18g yttrium chloride, further reflux hydrolysis, until the solution is completely clear and transparent. The solution was distilled under reduced pressure at 60° C. and dehydrated to a concentration of 30 wt % to obtain the final colloid.

Embodiment 3

[0031] Put 323 zirconium carbonate powder in water to form a suspension, filter to remove impurities and set aside. Weigh 78.5g of industrial hydrochloric acid with a concentration of 31wt%, dilute it to 8wt%, add it to the reflux device, and heat up to 50°C; add the zirconium carbonate powder treated above into the hydrochloric acid solution, stir and heat to 90°C until completely Dissolve; add 7.9g of yttrium acetate, further reflux and hydrolyze until the solution is completely clear and transparent. The solution was distilled under reduced pressure at 70° C. and dehydrated to a concentration of 40 wt % to obtain the final colloid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com