Amino ethyl xanthogenic acid cyanogen ethyl ester compound and preparation method as well as collector thereof

A technology for synthesizing aminoethylxanthate cyanoethyl ester and aminoethylxanthate, which is applied in organic chemistry, solid separation, flotation, etc., and achieves the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: A kind of diethylamino ethyl xanthate cyanoethyl ester and preparation method thereof

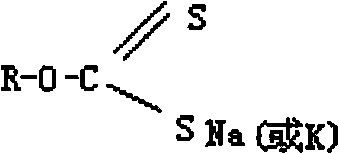

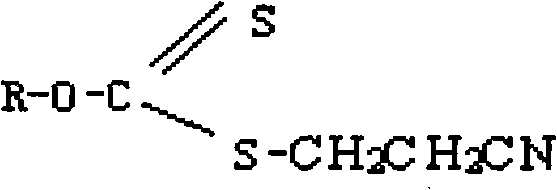

[0055] The structural formula of diethylaminoethyl xanthate cyanoethyl ester compound is:

[0056]

[0057] The raw materials and their weights used in the preparation method are: 73g of diethylamine, 80.5g of chloroethanol, 133g of 30% aqueous sodium hydroxide solution, 76g of carbon disulfide, and 53g of acrylonitrile, including the following two steps:

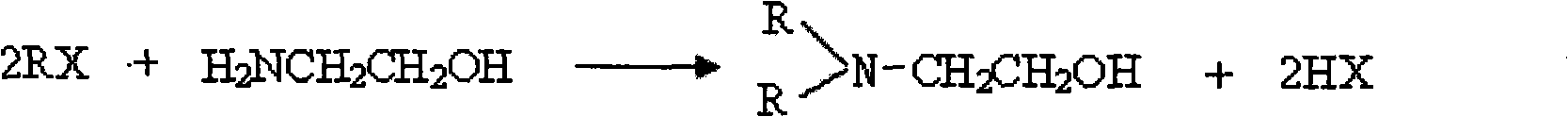

[0058] (1) Take 73g of diethylamine and put it into the reaction bottle, start stirring, add dropwise 80.5g of chloroethanol, then dropwise add 133g of 30% aqueous sodium hydroxide solution, control the reaction temperature to not exceed 50°C, continue stirring after the dropwise addition React at 50° C. for 1 h, then stand to cool and separate the layers, and the oil layer is separated to obtain diethylaminoethanol, and a total of 117 g is obtained.

[0059] (2) Take 117g of diethylamine ethanol and 76g of carbo...

Embodiment 2

[0060] Embodiment 2: A kind of diethylamino ethyl xanthate cyanoethyl ester and preparation method thereof

[0061] The raw materials and their weights used in the preparation method are: 129g of monochloroethane, 61g of aminoethanol, 266g of 30% aqueous sodium hydroxide solution, 76g of carbon disulfide, and 53g of acrylonitrile, including the following two steps:

[0062] (1) Add 129g of monochloroethane and 61g of aminoethanol into the reaction flask, start stirring and raise the temperature to 45-90°C, add dropwise 266g of 30% sodium hydroxide aqueous solution, and neutralize the hydrogen chloride produced by the reaction, about 0.5-1.5h After the dropwise addition, continue to stir and react at 45~90°C for 0.5~1.5h, then let it stand for cooling and separate the layers, and separate the oil layer, which is diethylaminoethanol, and a total of 116g is obtained.

[0063] (2) Put 116g of diethylaminoethanol and 76g of carbon disulfide into the reaction bottle together, contro...

Embodiment 3~22

[0064] Embodiment 3-22: A kind of cyanoethyl aminoxanthate and its preparation method

[0065] The raw materials used in each embodiment and the proportioning ratio are shown in Table 1, and the preparation method is the same as Example 1 or Example 2.

[0066] Table 1

[0067]

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com