Hydrocracking method for producing lube base oil

A lubricating base oil and hydrocracking technology, which is applied in lubricating compositions, hydrotreating process, petroleum industry, etc., can solve the problems of large investment, increased enterprise investment, and large manpower consumption, and achieve low overall investment and high process efficiency. The effect of simplified process and low labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

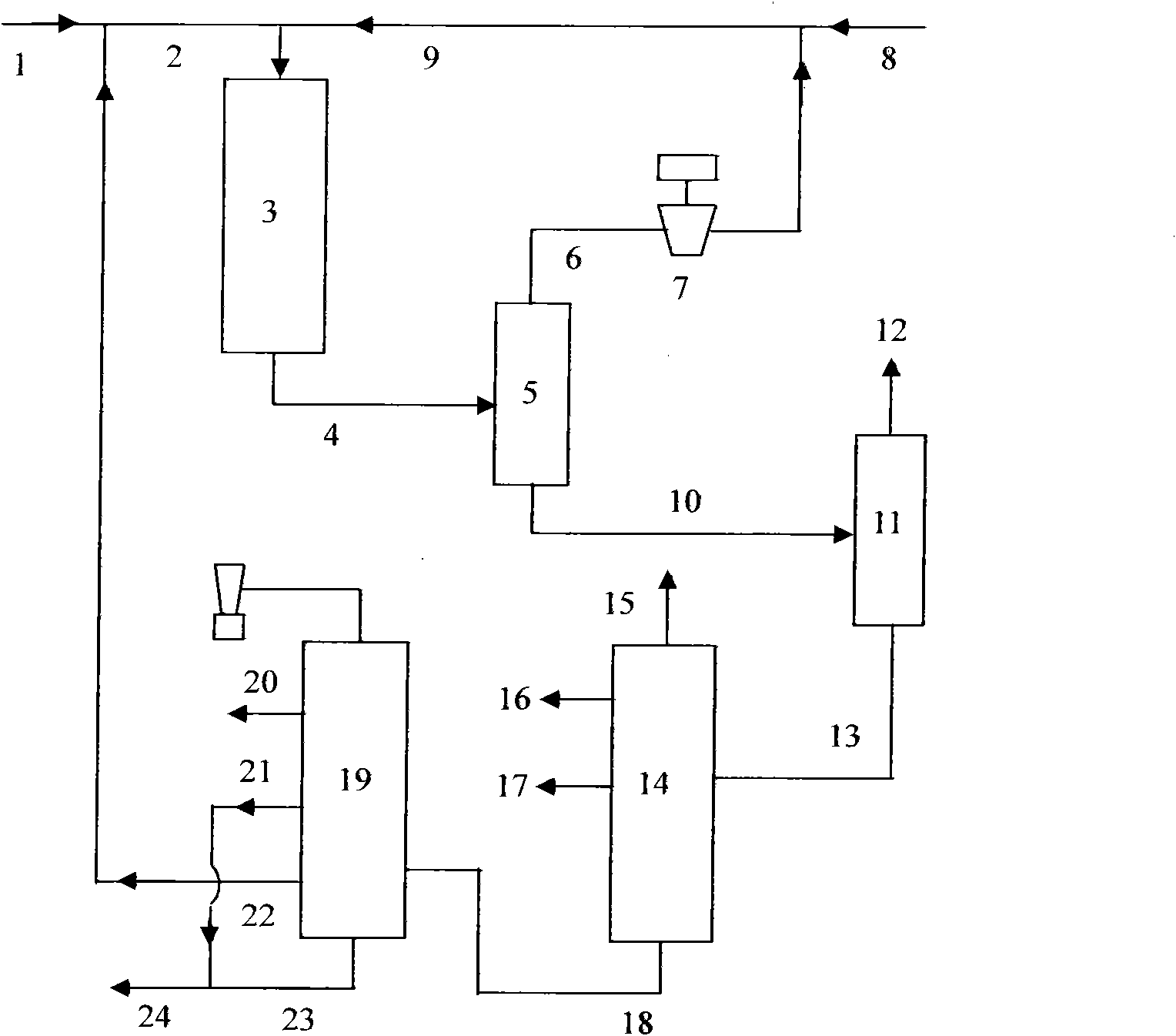

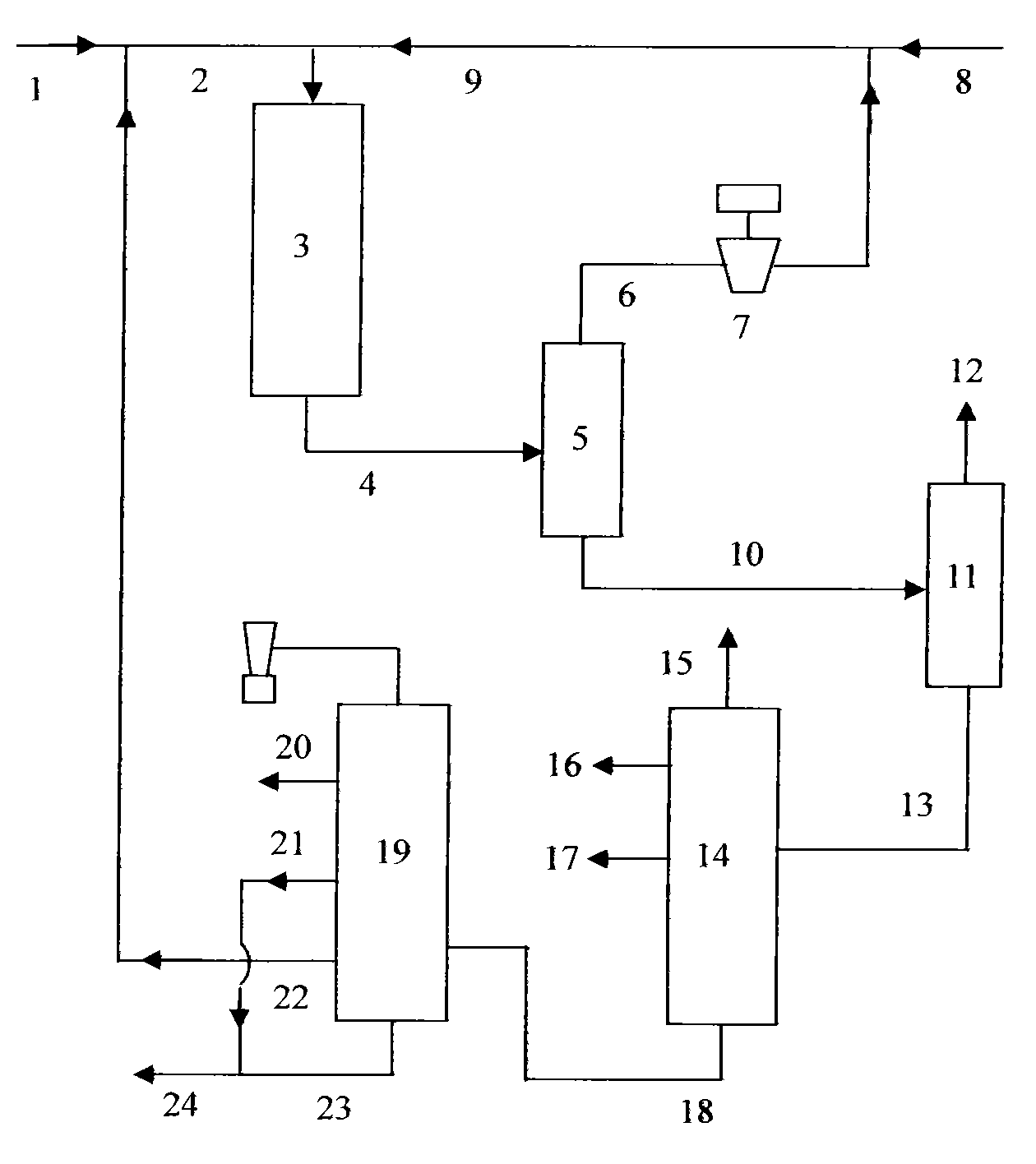

[0025] Such as figure 1 As shown, an implementation of the hydrocracking flexible cutting scheme of the present invention is as follows:

[0026] The fresh raw material 1 is mixed with the circulating intermediate tail oil 22, the obtained raw material oil 2 is mixed with hydrogen gas 9, and then enters the hydrocracking unit 3, the reaction effluent 4 enters the separation system 5, and the obtained gas 6 passes through the circulating hydrogen compressor 7 , and mixed with new hydrogen 8 to obtain hydrogen 9, which is recycled to the reactor inlet or used as quenched hydrogen at the same time; the liquid 10 obtained by the separation system 5 enters the stripping tower 11, and the top part of the tower gives out the top gas 12, and the bottom of the stripping tower The liquid phase 13 obtained enters the atmospheric fractionation tower 14, and light naphtha 15, heavy naphtha 16 and aviation kerosene 17 are sequentially fractionated from top to bottom, and the liquid phase 18...

Embodiment 1

[0031] use figure 1 As shown in the process flow, the cutting scheme of the decompression part of the fractionation system is flexibly adjusted, the tail oil 1 is cut into three different components of light, medium and heavy, and the middle tail oil (415℃~445℃) is recycled back to In the reaction part, light tail oil and heavy tail oil are mixed into tail oil 2.

[0032]The properties of the catalysts used in the examples are listed in Table 1. The catalyst is a commercial catalyst developed and produced by Fushun Petrochemical Research Institute. The properties of the raw oil are shown in Table 2, and the operating conditions of the hydrogenation process are shown in Table 3.

Embodiment 2

[0036] The raw material oil is the mixed raw material oil of VGO and DAO in the Middle East, the intermediate tail oil (430℃~460℃) is recycled to the reaction part, and the light tail oil and heavy tail oil are mixed into tail oil 4. Other conditions are with embodiment 1

[0037] Table 1 Main physicochemical properties of the catalyst

[0038] project

[0039] Table 2 Raw Oil Properties Table

[0040] project

[0041] Table 3 reaction conditions

[0042] Example 1

[0043] Table 4

[0044] Comparative example 1

[0045] It can be seen from the above examples that the biggest feature of the hydrocracking method of the present invention is that, compared with the conventional product cutting method, the pour point of the tail oil can be lowered by 4-5°C, so that the downstream shape-selective isomerization can be eliminated It can directly produce high-quality low-point lubricating base oil and improve the economic benefits of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com