Hybrid inorganic/organic polymer catalytic membrane material including immobilized molecular catalyst and its preparation

A technology of molecular catalysts and catalytic materials, applied in the field of new catalytic hybrid inorganic/polymer materials, can solve the problem of no reactor, no method of manufacturing polymer catalytic membranes, and unsuccessful development of polymer catalytic membranes And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

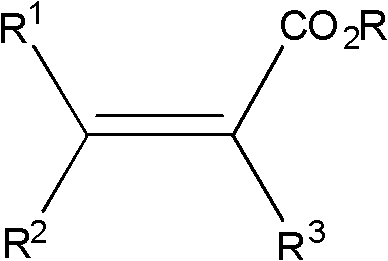

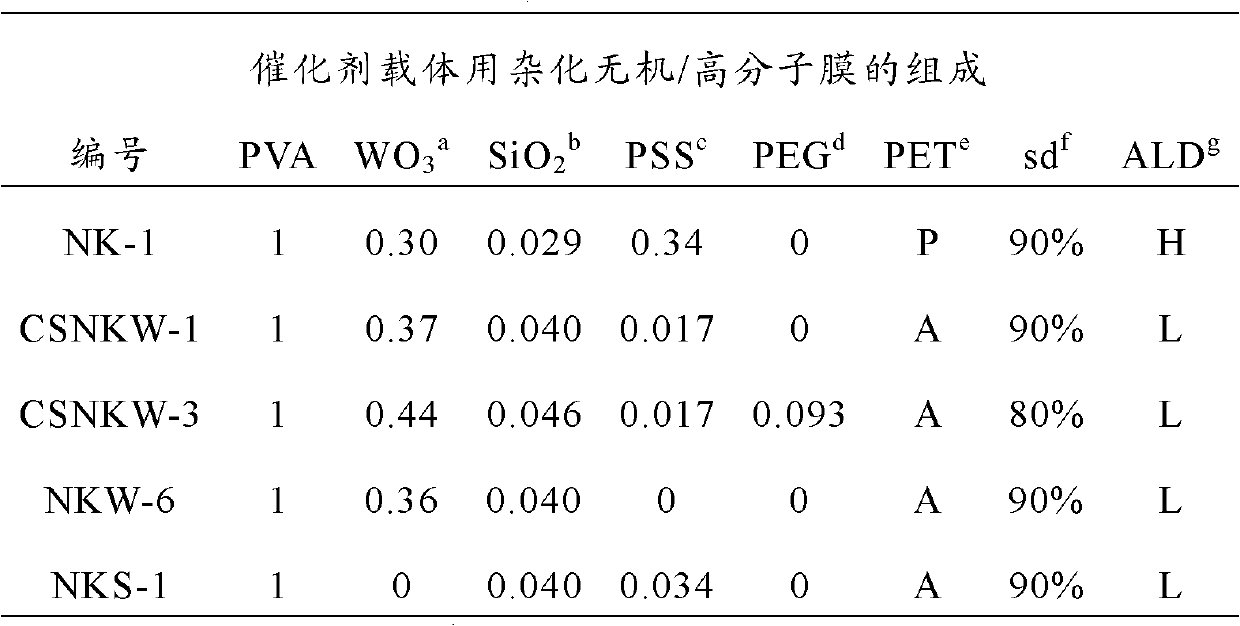

[0048] This example illustrates the general procedure for preparing immobilized hybrid inorganic / polymeric materials, especially membranes, for preformed molecular catalysts. The raw material aqueous solution is passed through a predetermined amount of sodium silicate and / or sodium tungstate dihydrate (Na 2 WO 6 2H 2 O) obtained by mixing into 100 ml of 10% by weight polyvinyl alcohol solution. PVA has an average degree of polymerization of 3100-3900 and a degree of saponification of 86-90%. A hydrochloric acid solution having a concentration of 2.4 M was added dropwise to the raw material aqueous solution under stirring for co-existing neutralization, which induced a hybridization reaction.

[0049] The precursor solution was cast on the polyester film of the coating device with the plate heated to a temperature of 60-80°C. The coating equipment was an RK Print Coat Instruments Ltd. electric coater (Kcontrolcoater) having a doctor blade for adjusting the gap with a microm...

Embodiment II

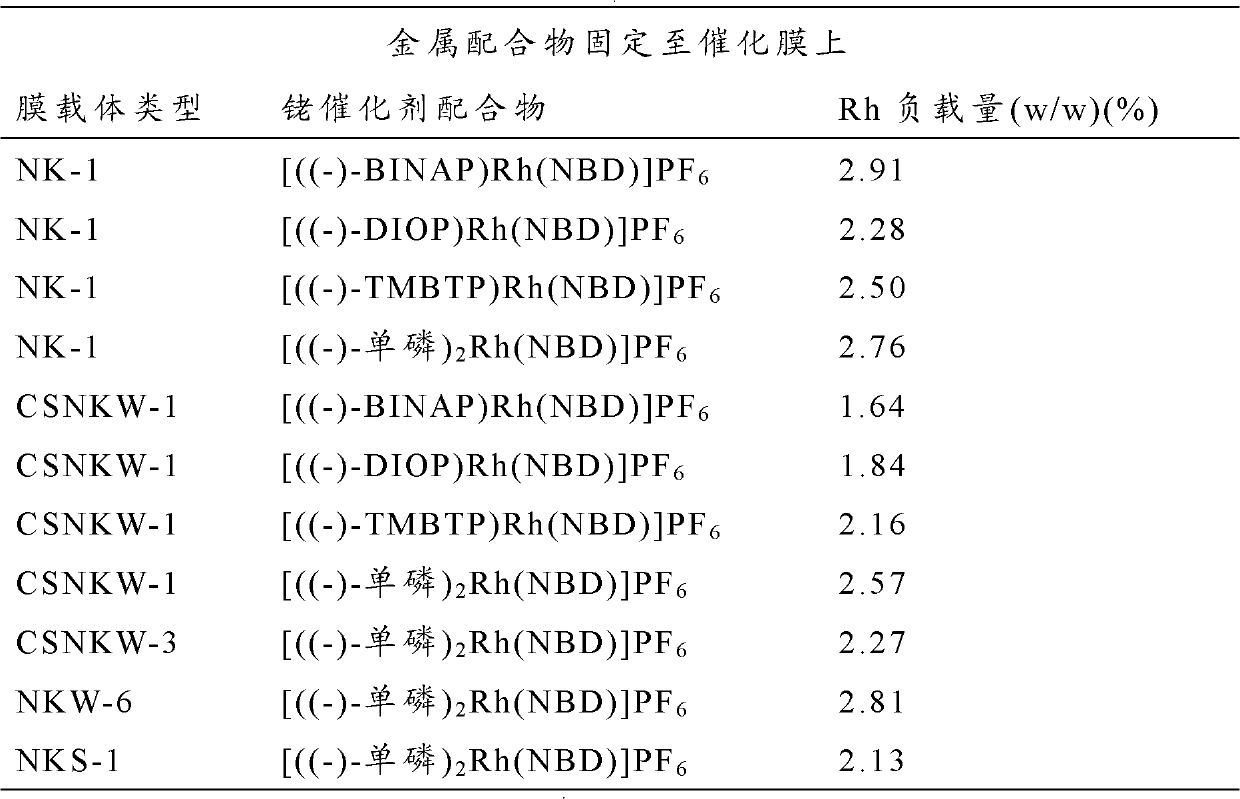

[0053] This example illustrates the general procedure for preparing a catalytic membrane by immobilizing a pre-formed metal catalyst on a hybrid inorganic / polymer membrane prepared as described in Example I according to the method of the invention as described above.

[0054] will be in 2 1cm clamped between windows 2 Hybrid inorganic / PVA membrane support samples were introduced into round bottom glass flasks equipped with lateral stopcocks. Methanol (10 mL) was introduced into the flask degassed with three vacuum / nitrogen cycles. The pre-formed metal complex catalyst (3.10 -3 mmol) of nitrogen degassed solution was passed under nitrogen flow Capillary transfer to flask. The flask was stirred at room temperature for 24 h by means of an orbital shaker. Afterwards, the methanol solution was removed from the flask by decantation under a nitrogen flow, the membrane was carefully washed with sequential addition / removal of degassed MeOH portions (3×15 mL) and dried under a ni...

Embodiment III

[0057] This example illustrates: according to the method of the invention as described in the preceding examples, based on the immobilization of a pre-formed rhodium catalyst [((-)-BINAP)Rh( NBD)]PF 6 Steps to prepare the catalytic membrane.

[0058] will be in 2 1cm clamped between windows 2 (6.76 mg) hybrid inorganic / PVA membrane carrier type NK-1 was introduced into a round bottom glass flask fitted with a side stopper. Methanol (10 mL) was introduced into the flask degassed with three vacuum / nitrogen cycles. The preformed rhodium catalyst [((-)-BINAP)Rh(NBD)]PF in methanol (5 mL) was then 6 (3.00mg, 3.1·10 -3 mmol) of nitrogen degassed solution was passed under nitrogen flow Capillary transfer to flask. The flask was stirred at room temperature for 24 h by means of an orbital shaker. Afterwards, the methanol solution was removed from the flask by decantation under a nitrogen flow, the membrane was carefully washed with sequential addition / removal of degassed MeOH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com