Growth method of terbium gallium garnet crystal

A technology of terbium gallium garnet and a growth method, which is applied in the field of preparing doped terbium gallium garnet magneto-optical crystals, can solve the problems of small crystal size, difficulty in industrialized production, and complicated process compared with the pulling method, and achieves the advantages of suppressing volatilization, Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

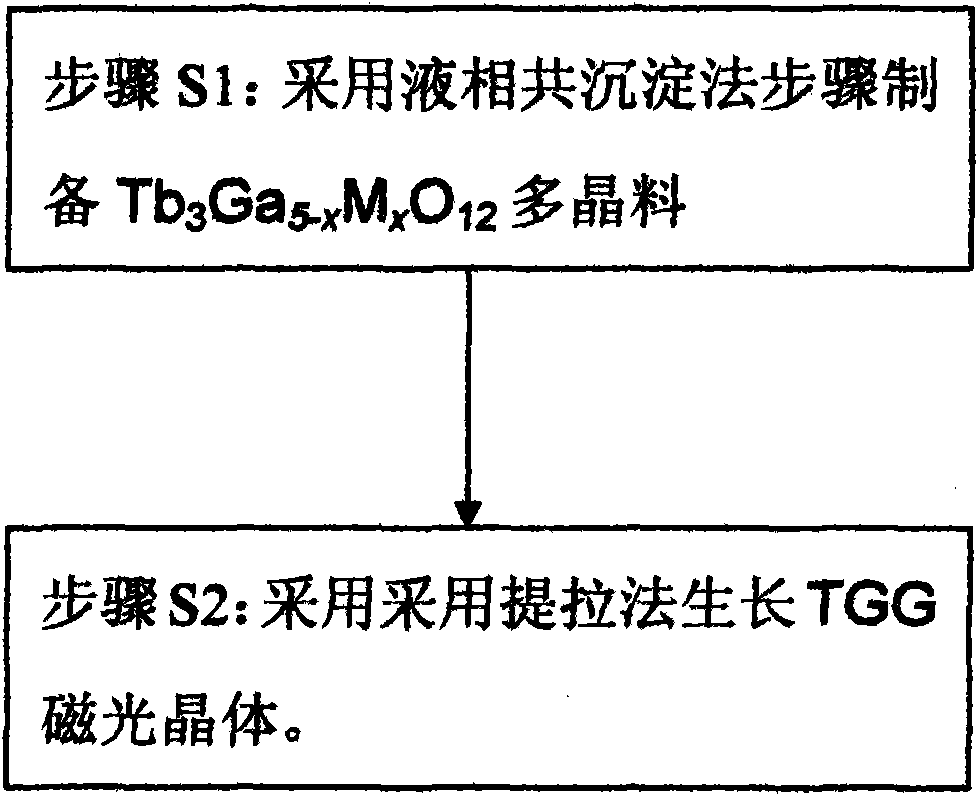

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: use commercial high-purity raw material, by molar ratio Tb 2 o 3 :(Ga 2 o 3 +Al 2 o 3 )=3:5.10 (Material A) and Tb 2 o 3 :(Ga 2 o 3 +Al 2 o 3 )=3:5.15 (Material B) Weigh high-purity Tb 4 o 7 , Ga 2 o 3 and Al 2 o 3 , wherein the aluminum ion doping concentration x is 0.15, and Tb is prepared according to the above-mentioned liquid phase co-precipitation method steps 3 Ga 4.85 al 0.15 o 12 polycrystalline material. Material B is used as the original material, and material A is used as the added material. Al-doped TGG crystals were grown by the pulling method according to the process of seeding, necking, shouldering, equal diameter, and finishing. The pulling speed was 0.8mm / h and the rotation speed was 12r / min. After annealing, a completely transparent aluminum-doped TGG crystal with a diameter of 25 mm and a length of 45 mm was obtained. The Verdet constant measured at 1064nm at room temperature is 0.145min / (Oe·cm).

Embodiment 2

[0032] Embodiment 2: use commercially available high-purity raw material, by molar ratio Tb 2 o 3 :(Ga 2 o 3 +Fe 2 o 3 )=3:5.10 (Material A) and Tb 2 o 3 :(Ga 2 o 3 +Fe 2 o 3 )=3:5.15 (Material B) Weigh high-purity Tb 4 o 7 , Ga 2 o 3 and Fe 2 o 3 , wherein the iron ion doping concentration x is 0.15, and Tb is prepared according to the above-mentioned liquid phase co-precipitation method 3 Ga 4.85 Fe 0.15 o 12 polycrystalline material. Material B is used as the original material, and material A is used as the added material. The iron-doped TGG crystals were grown by the pulling method according to the process of seeding, necking, shouldering, equal diameter, and finishing. The pulling speed was 0.8mm / h and the rotation speed was 12r / min. After annealing, a completely transparent iron-doped TGG crystal with a diameter of 25 mm and a length of 40.5 mm was obtained. The Verdet constant at 1064nm measured at room temperature is 0.14min / (Oe·cm).

Embodiment 3

[0033] Embodiment 3: use commercially available high-purity raw material, by molar ratio Tb 2 o 3 :(Ga 2 o 3 +Al 2 o 3 +Fe 2 o 3 )=3:5.10 (Material A) and Tb 2 o 3 :(Ga 2 o 3 +Al 2 o 3 +Fe 2 o 3 )=3:5.15 (Material B) Weigh high-purity Tb 4 o 7 , Ga 2 o 3 、Al 2 o 3 and Fe 2 o 3 , where the doping concentration x of aluminum ions is 0.15, and the doping concentration x of iron ions is 0.15, and Tb is prepared according to the steps of the above-mentioned liquid phase co-precipitation method 3 Ga 4.7 al 0.15 Fe 0.15 o 12 polycrystalline material. Material B is used as the original material, and material A is used as the added material. Al-doped TGG crystals were grown by the pulling method according to the process of seeding, necking, shouldering, equal diameter, and finishing. The pulling speed was 0.8mm / h and the rotation speed was 12r / min. After annealing, a completely transparent Al-doped TGG crystal with a diameter of 25.6 mm and a length of 43 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Field constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com