Method for reducing allergenicity of special soybean isolation protein of soy-based infant formula powder

A soy protein isolate and infant-based technology, which is applied in protein food processing, protein food ingredients, applications, etc., can solve the problem that genetically modified raw materials cannot be used in infant formula food, etc., and achieves improvement of nitrogen solubility index, less energy consumption, and lower energy consumption. Allergenic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

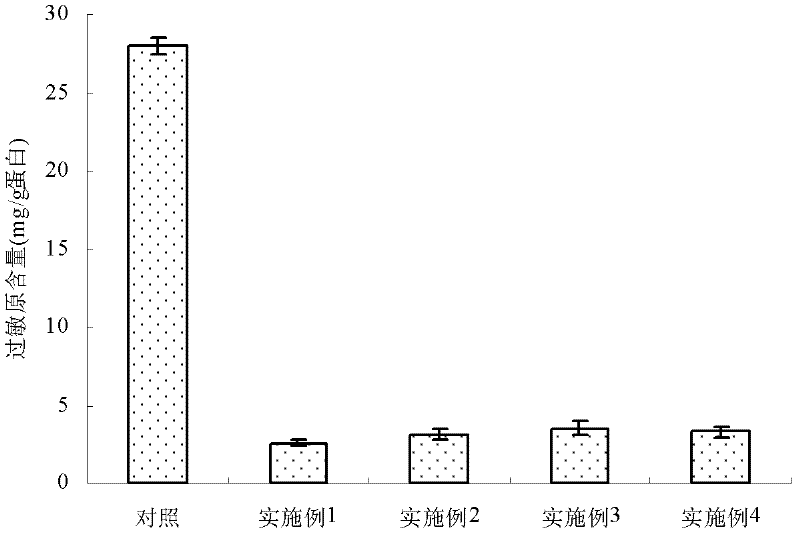

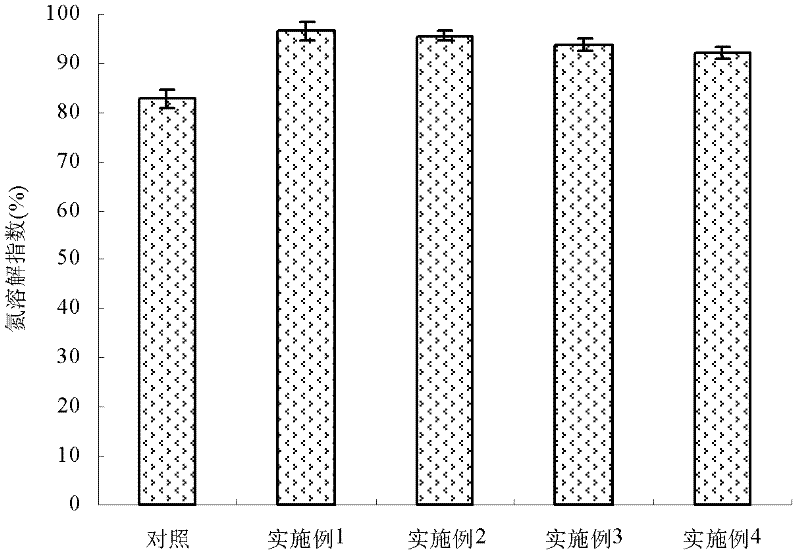

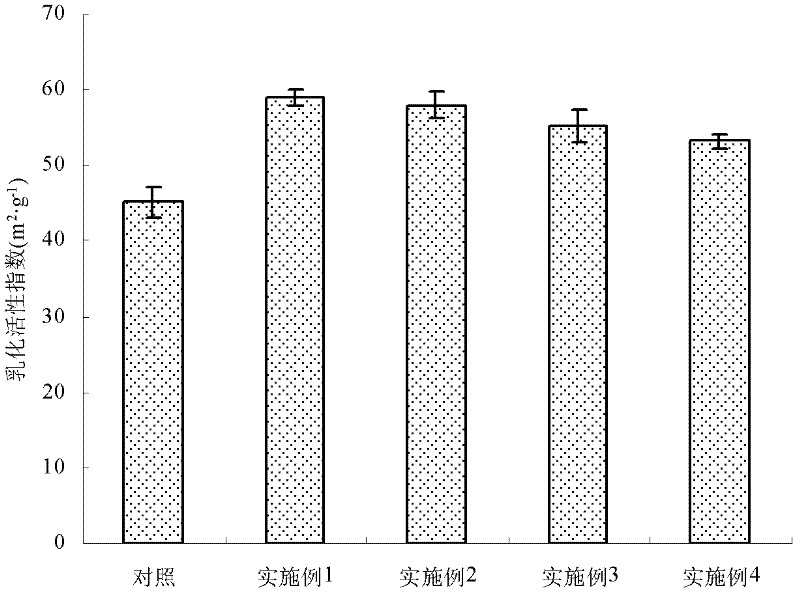

Examples

Embodiment 1

[0022] Production process: (1) Weigh a certain quality of soybean protein isolate, dissolve it in water according to the ratio of 1.06% (mass volume ratio is the amount of soybean protein isolate / volume of water), mix and prepare a uniform slurry, and then transfer it to an aluminum foil bag , seal and vacuumize; (2) Preheat the ultra-high static pressure water bath circulation device to 25°C, then place the soybean protein isolate in the ultra-high static pressure treatment chamber, increase the pressure to 352MPa, and the pressure increase rate is 250MPa / min, Keep the pressure for 16 minutes. After the time is up, the machine will automatically release the pressure quickly, and the pressure relief rate is 300MPa / min. (3) Concentrate the soybean protein isolate solution under the condition of 0.1MPa vacuum degree and 55° C. to 8% (mass volume ratio is soybean protein isolate quality / volume of water). (4) Transfer the soy protein isolate concentrate to the enzymolysis tank, ad...

Embodiment 2

[0032] Production process: (1) Weigh a certain quality of soybean protein isolate, dissolve it in water according to the ratio of 1.03% (mass volume ratio is the amount of soybean protein isolate / volume of water), mix and prepare a uniform slurry, and then transfer it to an aluminum foil bag , sealed and vacuumed; (2) The ultra-high static pressure water bath circulation device is preheated to 20°C, and then the soybean protein isolate is placed in the ultra-high static pressure treatment chamber, and the pressure is increased to 317MPa, and the pressure increase rate is 250MPa / min. The pressure is maintained for 19 minutes. After the time is up, the machine automatically releases the pressure quickly, and the pressure relief rate is 300MPa / min. (3) Concentrate the soybean protein isolate solution under the condition of 0.1MPa vacuum degree and 55° C., and concentrate to 9% (mass volume ratio is the soybean protein isolate quantity / volume of water). (4) Transfer the soy protei...

Embodiment 3

[0035] Production process: (1) Weigh a certain quality of soybean protein isolate, dissolve it in water according to the ratio of 1.65% (mass volume ratio is the amount of soybean protein isolate / volume of water), mix and prepare a uniform slurry, and then transfer it to an aluminum foil bag , sealed and vacuumed; (2) The ultra-high static pressure water bath circulation device is preheated to 24°C, and then the soybean protein isolate is placed in the ultra-high static pressure treatment chamber, and the pressure is increased to 382MPa, and the pressure increase rate is 250MPa / min. Keep the pressure for 18 minutes. After the time is up, the machine will automatically release the pressure quickly, and the pressure relief rate is 300MPa / min. (3) Concentrate the isolated soybean protein solution under the condition of 0.1MPa vacuum degree and 55° C. to 8.5% (mass volume ratio is the isolated soybean protein amount / volume of water). (4) Transfer the concentrated soy protein isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com