Method for preparing nanoscale magnesium nitride powder

A nano-scale, nano-magnesium technology, applied in nanotechnology, nitrogen-metal/silicon/boron binary compounds, etc., can solve the problems of toxicity, unfavorable large-scale production, high price, and achieve the effect of high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

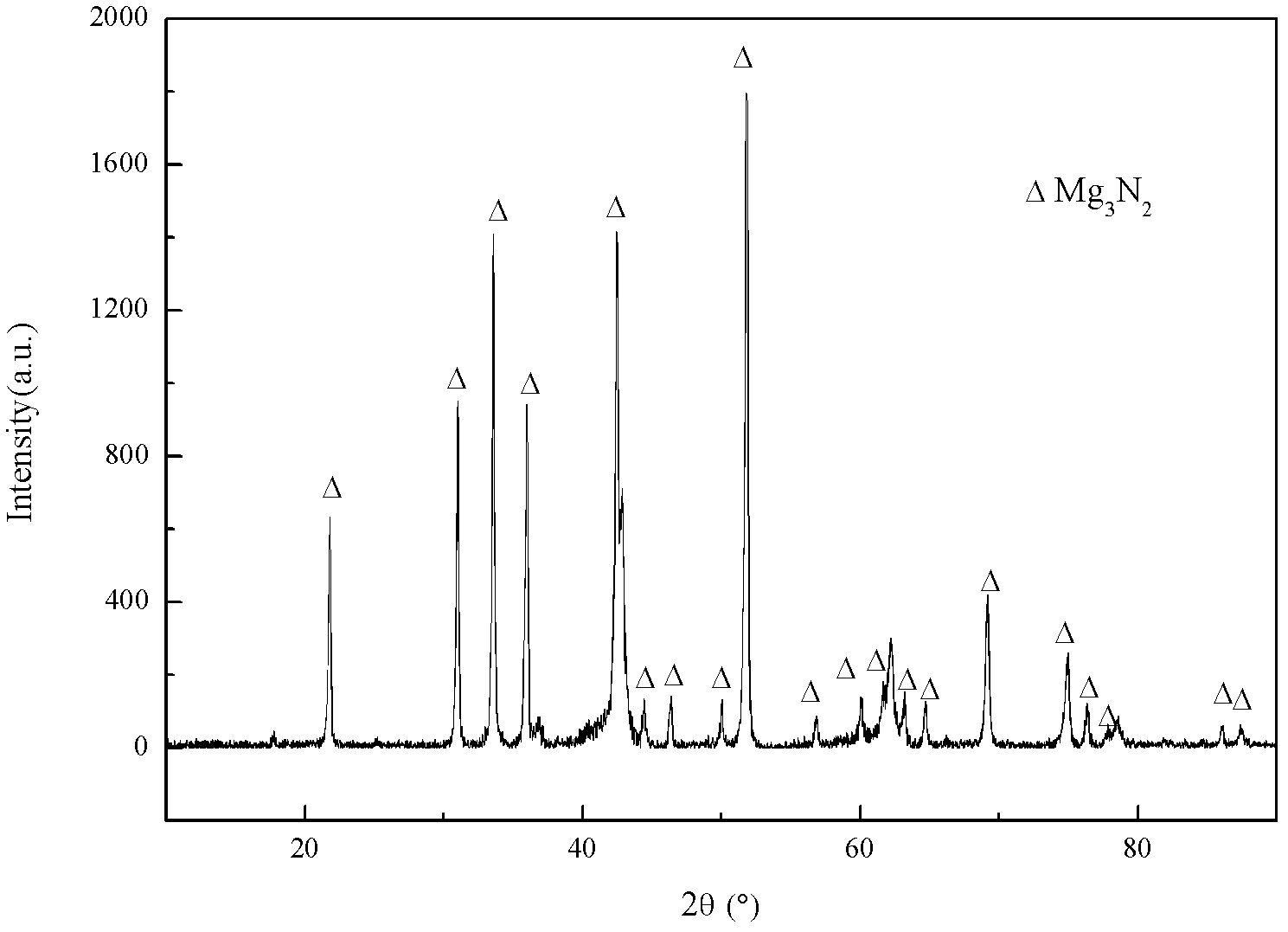

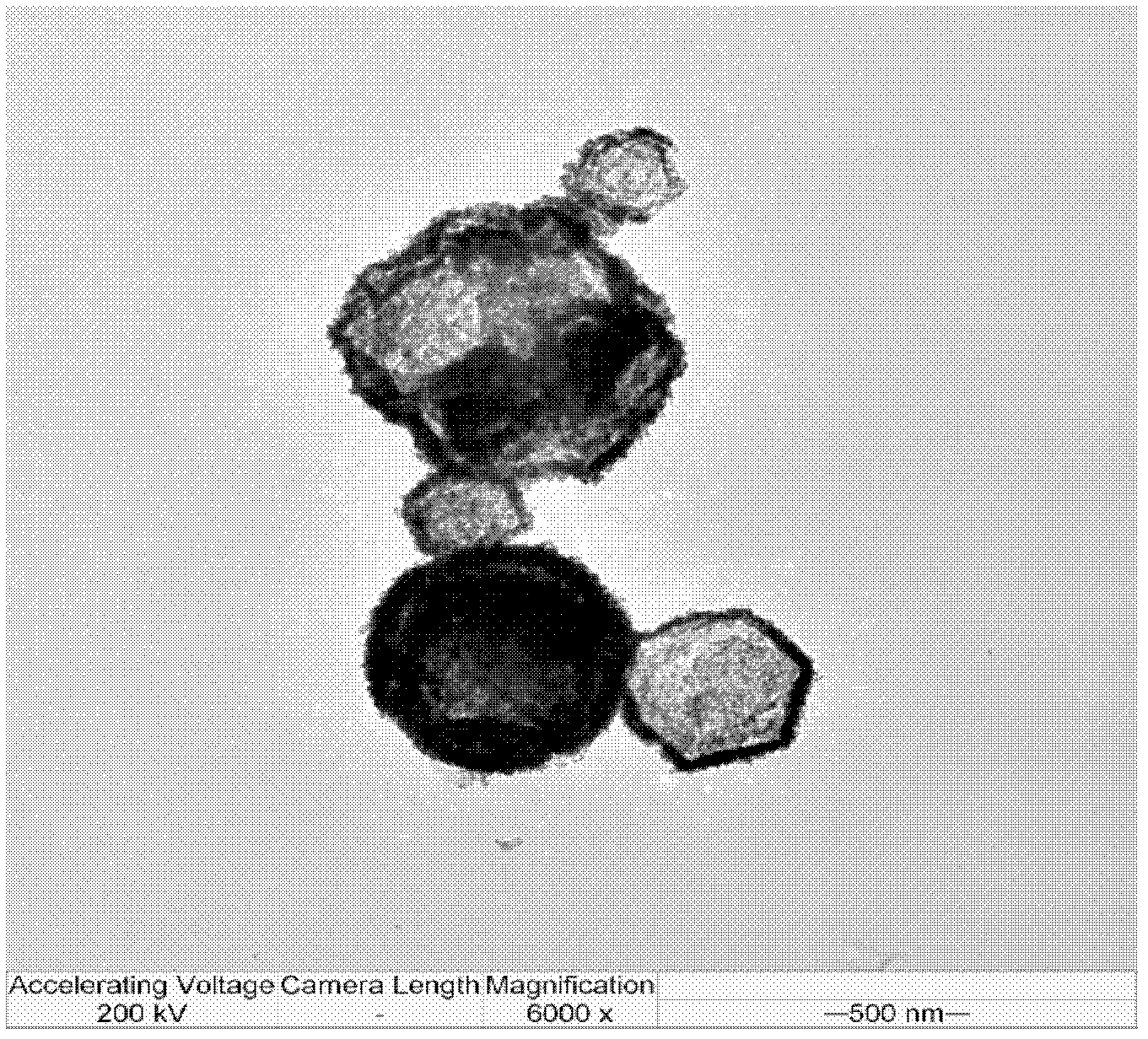

Embodiment 1

[0022] 1. Put a pure magnesium block (length 60mm, width 30mm, height about 10mm) with a smooth surface as the anode, and a tungsten rod as the cathode, and place it in the DC arc plasma equipment; when the device is pumped to a vacuum of 5×10 -2 At Pa, fill in 0.7atm argon and 0.1atm hydrogen; turn on the cooling water system (water pressure 2Mpa) and start the arc, adjust the current to 120A, continue to pass hydrogen to keep the equipment pressure at 0.8-1atm, react for 10min, and extinguish the arc After cooling to room temperature, turn off the cooling water system; vacuum the DC arc plasma equipment to 0.01Mpa; then fill it with 60KPa argon, then fill it with 5KPa air every half hour, and then fill it with 40Kpa air for passivation of the powder ,, the passivation time is 12 hours; collect the inner wall powder, which is the prepared nano-magnesium powder;

[0023] 2. Weigh 2g of the above-mentioned nano-magnesium powder and spread it evenly on the bottom of the ceramic ...

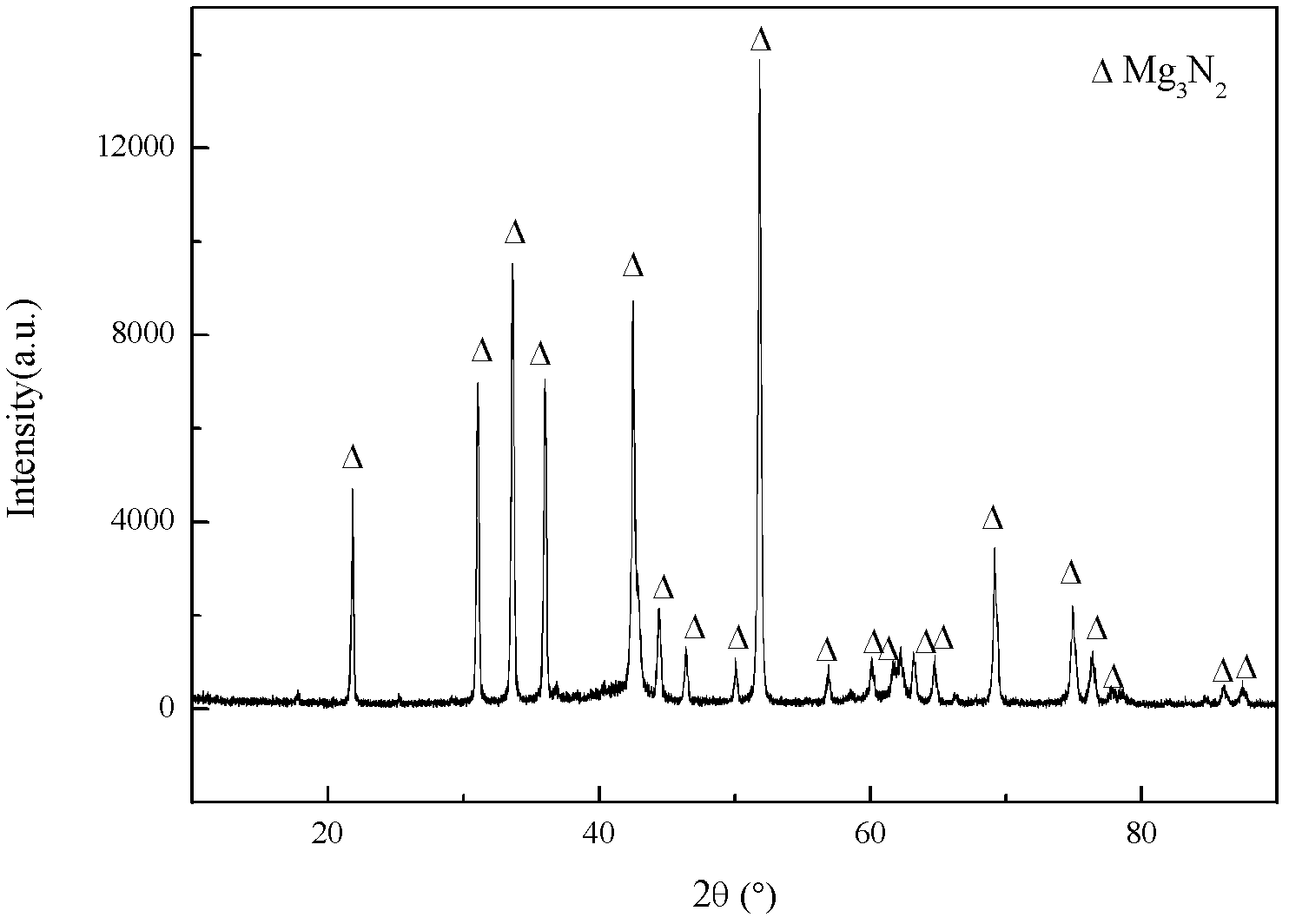

Embodiment 2

[0027] 1. Put a pure magnesium block (length 60mm, width 30mm, height about 10mm) with a smooth surface as the anode, and a tungsten rod as the cathode, and place it in the DC arc plasma equipment; when the device is pumped to a vacuum of 5×10-2Pa , fill in 0.7atm argon and 0.1atm hydrogen; turn on the cooling water system (water pressure 2Mpa) and start the arc, adjust the current to 120A, continue to pass hydrogen and keep the equipment pressure at 0.8-1atm to react for 20min, extinguish the arc, and cool down to room temperature; evacuate the DC arc plasma equipment to 0.01MPa, and then fill it with argon gas of 0.7atm and air of 0.3atm for passivation operation; after passivation, collect the inner wall powder, which is the prepared nano-magnesium powder;

[0028] 2. Weigh 2g of the above-mentioned nano-magnesium powder and spread it evenly on the bottom of the ceramic boat; put the ceramic boat with the magnesium powder into the quartz tube, then put it into the tube furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com