Cow dung biogas residue floriculture substrate and combining technology thereof

The technology of cultivation substrate and biogas residue is applied in the field of cow dung biogas residue flower cultivation substrate and its compounding process, which can solve the problems of restricting the healthy and orderly development of biogas projects, difficulty in slag removal from biogas digesters, and low added value, etc. Natural peat resources, excellent physical and chemical properties, and the effect of realizing resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

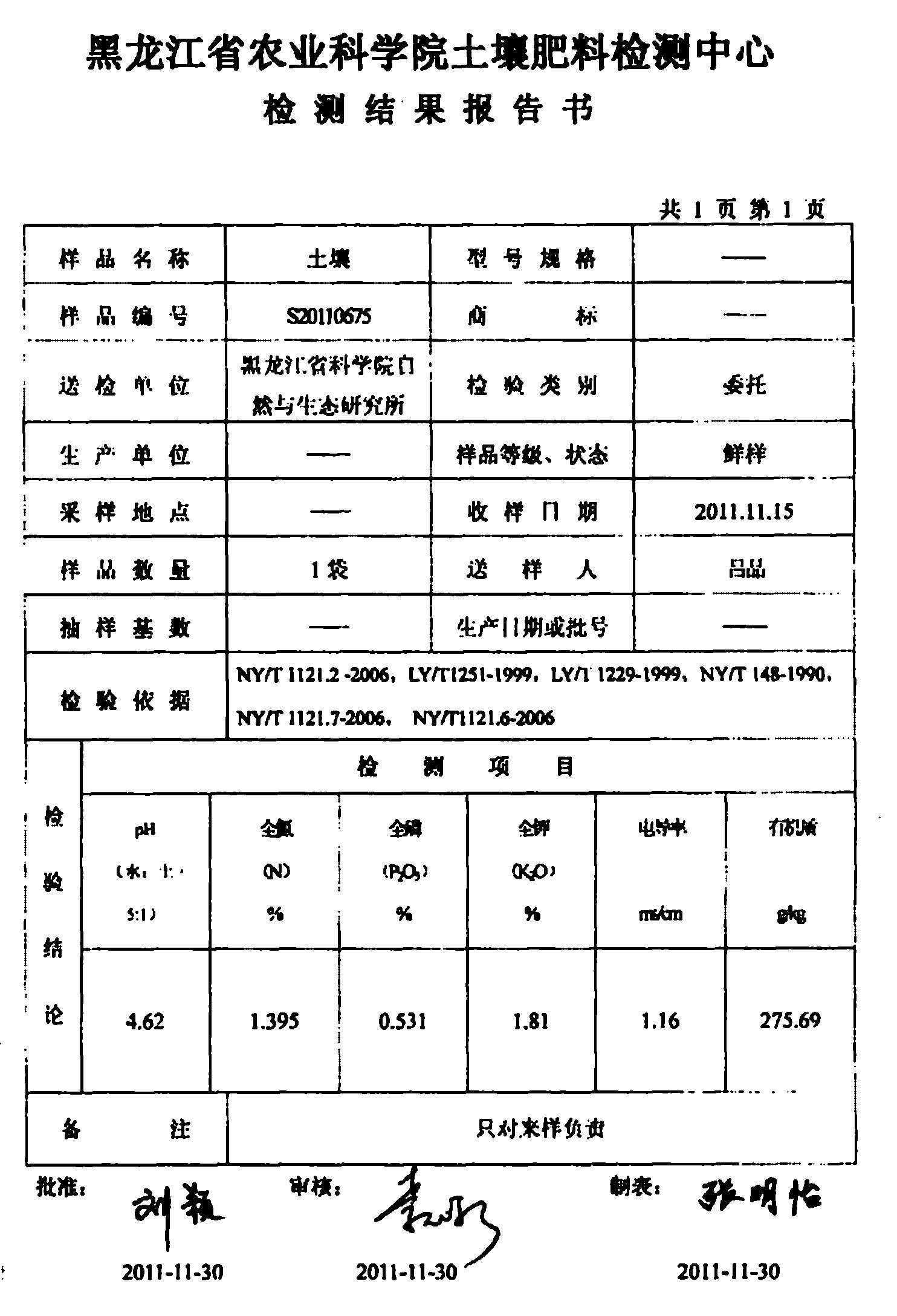

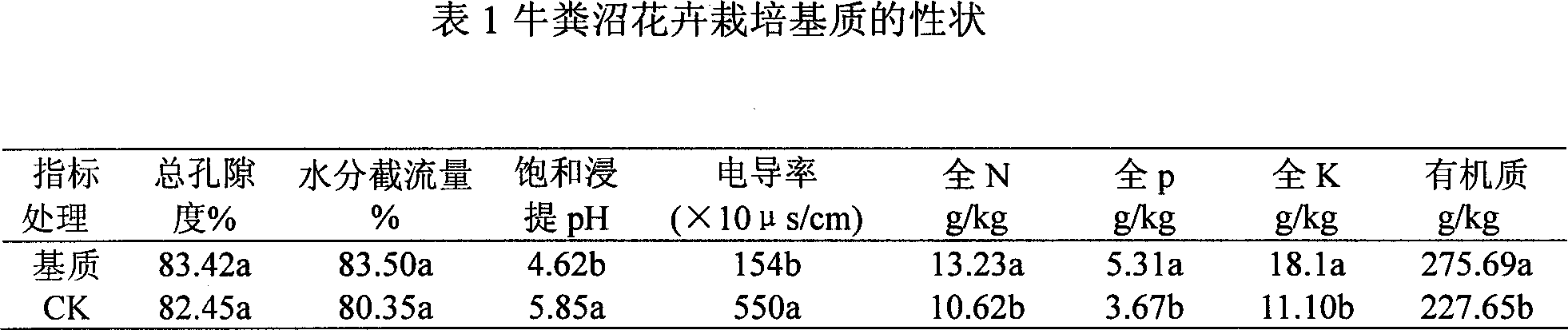

[0020] Cow dung and biogas residue, flattened and air-dried, after crushing larger clumps, compounded with air-dried miscellaneous wood chips, 0.5m 3 Biogas residue and 0.5m 3 The sawdust is mixed evenly, and 15L of phosphoric acid solution diluted 200 times by volume is sprayed and stirred on the substrate with a watering can to obtain the following: figure 2 The nutrient matrix shown is suitable for slightly acidic flowers, its index is pH4.5-5.5, nutrient content NPK≥35g.kg -1 , conductivity 1.1-1.2ms.cm -1 , porosity 80-85%.

Embodiment 2

[0022] Cow dung and biogas residue, flattened and air-dried, after crushing larger clumps, compounded with air-dried miscellaneous wood chips, 0.5m 3 Biogas residue and 0.5m 3 The sawdust is mixed evenly, and 22.5L of phosphoric acid solution diluted 300 times by volume is sprayed and stirred on the substrate with a watering can to obtain the following: figure 2 The nutrient matrix shown is suitable for slightly acidic flowers, its index is pH4.5-5.5, nutrient content NPK≥35g.kg -1 , conductivity 1.1-1.2ms.cm -1 , porosity 80-85%.

Embodiment 3

[0024] Cow dung and biogas residue, flattened and air-dried, after crushing larger clumps, compounded with air-dried miscellaneous wood chips, 0.5m 3 Biogas residue and 0.5m 3 The sawdust is mixed evenly, and 30L of phosphoric acid solution diluted 400 times by volume is sprayed and stirred on the substrate with a watering can to obtain the following: figure 1 The nutrient matrix shown is suitable for slightly acidic flowers, its index is pH4.5-5.5, nutrient content NPK≥35g.kg -1 , conductivity 1.1-1.2ms.cm -1 , porosity 80-85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com