Preparation method, product and application of compound with hazel characteristic aroma

A technology for characteristic aromas and compounds, applied in the field of 5-methyl-4-heptanone compounds, can solve problems such as raw hazelnuts without data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

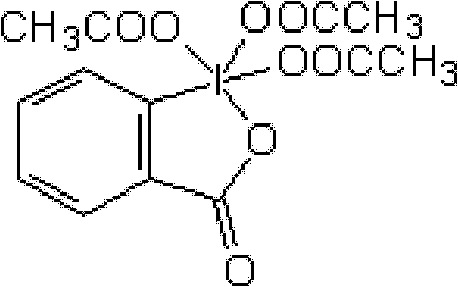

Image

Examples

Embodiment 1

[0070] Example 1 : Synthesis of a Hazelnut Characteristic Aroma Compound

[0071] The implementation steps of this embodiment are as follows:

[0072] A) Dissolve 2ml of 2-butanone in 30mL of anhydrous ether, then slowly add the obtained 2-butanone solution into 5mL of phosphorus tribromide, stir and mix evenly under a nitrogen atmosphere at a temperature of 0-5°C. After mixing, heat up to 22°C, stir and react at this temperature for 24 hours; then add 50g of crushed ice, extract twice with 200mL ether after the ice is completely dissolved, combine the separated organic phases, and then use 100mL of 0.5M carbonic acid Elute with sodium solution, separate the organic phase and remove the moisture contained in the organic phase with granular anhydrous sodium sulfate, then concentrate under reduced pressure at room temperature and pressure 0.05MPa to 2mL to obtain intermediate product A;

[0073] Detection was carried out according to the method described in the specification o...

Embodiment 2

[0081] Take 4g of 2-butanone dissolved in 15g of anhydrous ether to form a solution, add 12g of phosphorus tribromide, stir and mix evenly under nitrogen atmosphere and temperature of 0°C, raise the temperature to 25°C and continue stirring for 22h.

[0082] Then, add 120g of ice to this reaction system, repeatedly extract 3 times with 500g of ether, discard the separated water phase, combine the separated organic phases, then carry out back extraction with 250g of 0.8M sodium carbonate solution, and discard the separated water phase , the separated organic phase was dehydrated with anhydrous sodium sulfate, and then concentrated under reduced pressure at room temperature to obtain intermediate product A.

[0083] Then, add 4g of magnesium powder and 5g of anhydrous ether to the clean reactor, place in an ice-water bath, then add 4g of anhydrous ether solution of intermediate product A; then add 0.5g of crystalline iodine, and stir the reaction in an ice-water bath 30min.

[...

Embodiment 3

[0091] Take 1g of 2-butanone dissolved in 60g of anhydrous ether to form a solution, add 5g of phosphorus tribromide, stir and mix evenly under nitrogen atmosphere and temperature of 5°C, raise the temperature to 20°C and continue stirring for 28h.

[0092] Then, add 30g of ice to this reaction system, extract repeatedly 4 times with 120g of diethyl ether, discard the separated aqueous phase, combine the separated organic phases, then back-extract with 250g of 0.2M sodium carbonate solution, discard the separated aqueous phase , the separated organic phase was dehydrated with anhydrous sodium sulfate, and then concentrated under reduced pressure at room temperature to obtain intermediate product A.

[0093] Then, add 1g of magnesium powder and 12g of anhydrous ether to the clean reactor, place it in an ice-water bath, then add 1g of anhydrous ether solution of intermediate product A; then add 0.1g of crystalline iodine, and stir the reaction in an ice-water bath 1h.

[0094] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com