Bonding agent for stemming and preparation method thereof

A technology of binder and gun clay, which is applied in the field of binder for gun clay and its preparation, which can solve the problems of environmental pollution, insufficient extrusion length of gun clay, and easy thickening of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The embodiment of the invention discloses a method for preparing a binder for gun clay, comprising the following steps:

[0025] a), under the condition that basic catalyst exists, phenol and formaldehyde take place polymerization reaction, obtain resole phenolic resin, the mol ratio of described phenol, formaldehyde and basic catalyst is 1: (1.2~2): (0.01~0.1 ); The resole phenolic resin is mixed with the first organic solvent to obtain a resole phenolic resin solution;

[0026] b), in the presence of an acidic catalyst, phenol and formaldehyde undergo a condensation reaction to obtain a novolak resin, the molar ratio of the phenol, formaldehyde and the acidic catalyst being 1: (0.5-0.9): (0.01-0.4); Dissolving the novolac resin in a second organic solvent to obtain a novolac resin solution;

[0027] c), described resole phenolic resin solution and novolak resin solution are mixed uniformly, obtain the bonding agent for blasting clay, the mass ratio of resole phenolic...

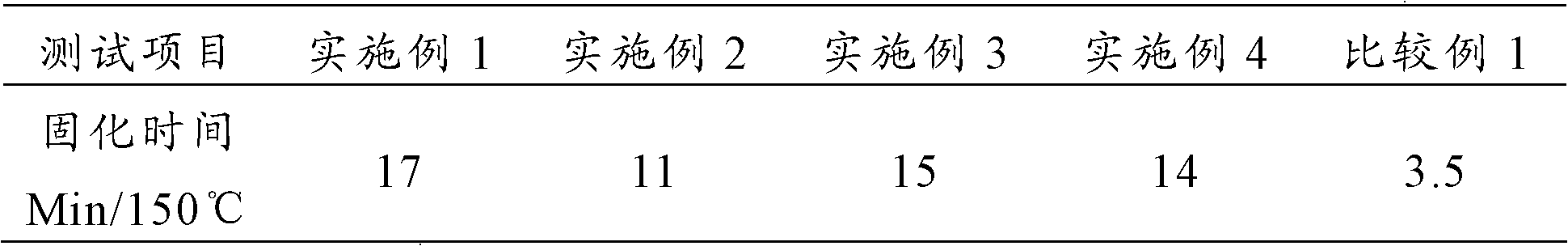

Embodiment 1

[0042] Phenol, formaldehyde and sodium hydroxide solution (concentration: 48%) are fed in a molar ratio of 1:1.43:0.04, stirred at 75°C for 5 hours, and further condensed after dehydration under reduced pressure to obtain a resole phenolic resin. Diethylene glycol is added to the resin to adjust the viscosity to 6300cp / 25°C to obtain a resole phenolic resin solution.

[0043] Feed phenol, formaldehyde and sulfuric acid (concentration: 25%) in a molar ratio of 1:0.77:0.01, raise the temperature to 90-100°C, and keep the temperature at this temperature for 3 hours to obtain a novolac resin, which is then dehydrated under reduced pressure to the novolak resin. Add ethylene glycol to the resin until the viscosity reaches 4800cp / 25°C to obtain a novolac resin solution.

[0044] The resole phenolic resin solution and the novolac resin solution are mixed according to the mass ratio of the resole phenolic resin to the novolak resin at a ratio of 1:2.5 times to obtain a binder for gun ...

Embodiment 2

[0046] Feed phenol, formaldehyde and sodium carbonate solution (concentration: 45%) in a molar ratio of 1:1.2:0.05, stir at 82°C for 3 hours, and further condense after dehydration under reduced pressure. The content of free phenol in the mixed solution is 7-9%. Terminate to obtain a resole phenolic resin, add furfuryl alcohol to the resole phenolic resin to adjust the viscosity to 11000cp / 25°C to obtain a resole phenolic resin solution.

[0047] Feed phenol, formaldehyde and sulfuric acid (concentration: 50%) in a molar ratio of 1:0.77:0.01, raise the temperature to 90-100°C, and keep the temperature at this temperature for 4 hours to obtain a novolac resin. Add ethylene glycol to the type phenolic resin until the viscosity is 3800cp / 25°C to obtain the novolak resin solution.

[0048] The resole phenolic resin solution and the novolac resin solution are mixed according to the mass ratio of the resole phenolic resin to the novolac resin at a ratio of 1:4.8 to obtain a binder f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com